Composition containing calcium conjugated linoleate and its preparation method

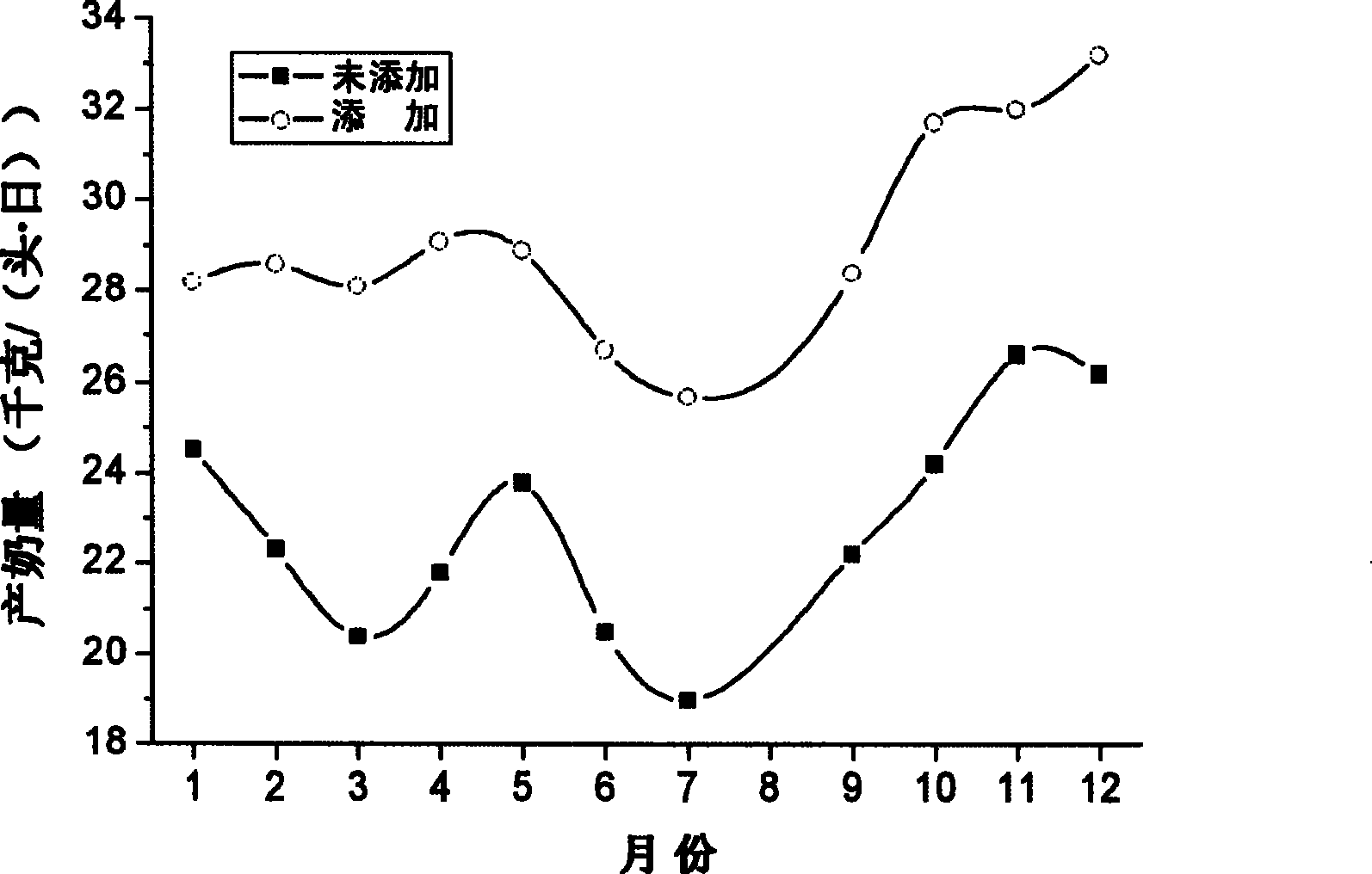

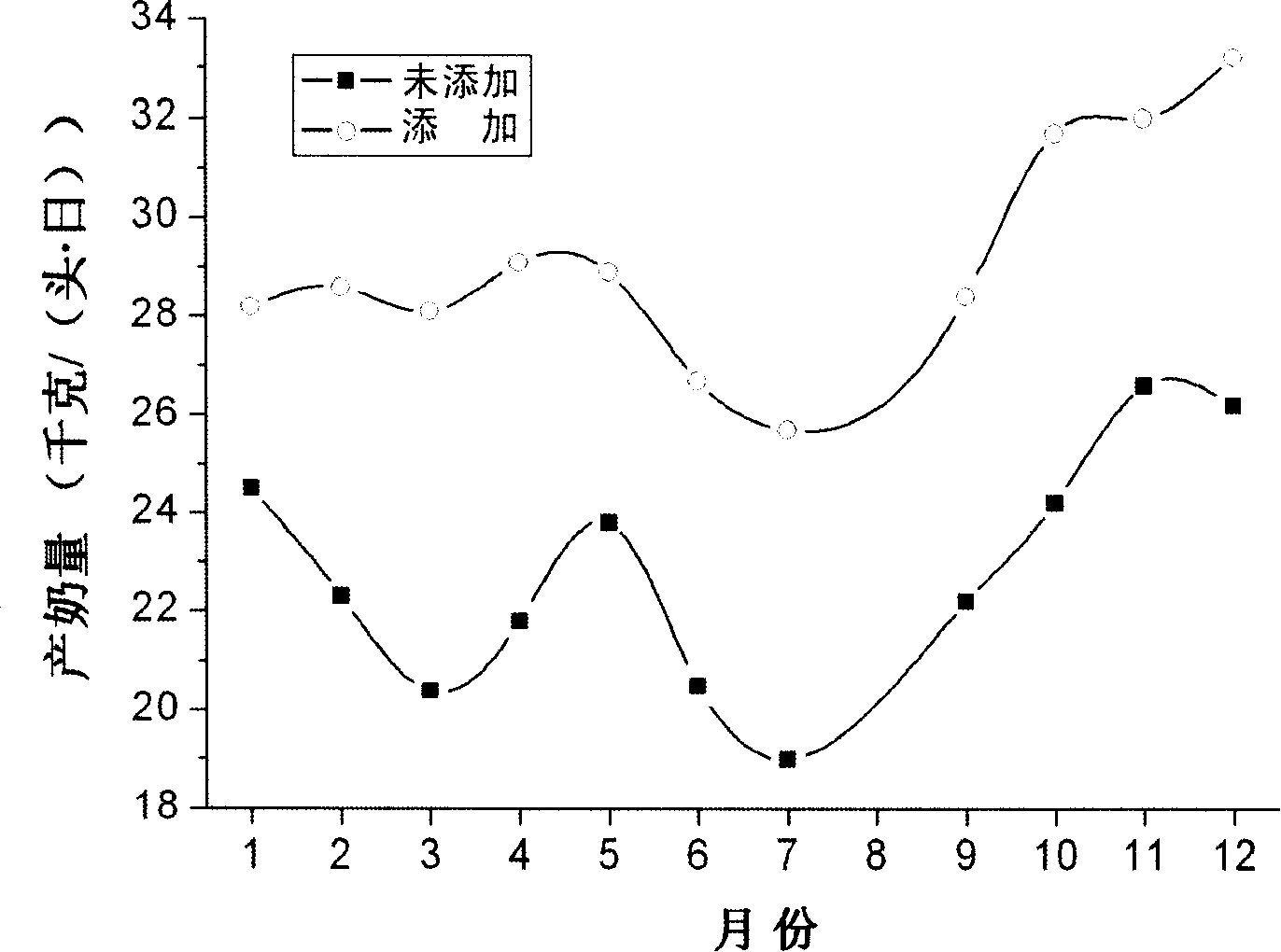

A technology of calcium conjugated linoleate and composition, applied in the field of high-purity calcium conjugated linoleate products and preparation thereof, can solve the problem that properties and colors are not very satisfactory, and the influence of milk production of dairy cows is not specifically reported, etc. problems, to achieve good physical properties, improve purity, and increase milk production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 4.8 liters of methanol and 81 grams of potassium hydroxide to 11 liters of sunflower oil, react at 35°C for 2 hours, separate out the glycerol after cooling down, then carry out molecular distillation at 6 Pa and 160°C to obtain 90% methyl linoleate. Take 7.5 liters of methyl linoleate, add 4 liters of methanol, 1.7 kg of potassium hydroxide, and react at 150° C. for 5 hours.

[0036] In a 50-liter reactor, add 16 liters of water and 14 liters of methanol to 7.5 kg of potassium salt rich in conjugated linoleic acid. After fully stirring and dissolving, slowly add concentrated hydrochloric acid to adjust the pH to 9-10, and slowly add 3.9 kg of 35% calcium chloride aqueous solution was added dropwise while stirring, the kettle temperature was controlled at about 30° C., reacted for 3 hours, suction filtered, and the filter cake was vacuum-dried to obtain the product.

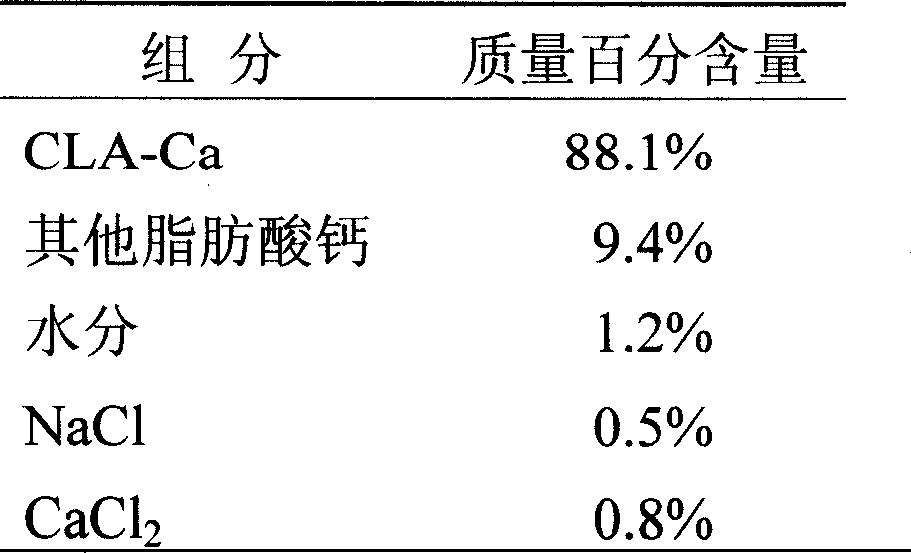

[0037] After analysis, the product is composed of the following components by mass percentage:

[...

Embodiment 2

[0045] Add 250 milliliters of methanol, 6 grams of caustic soda to 550 milliliters of safflower oil, react for 2.5 hours at 40° C., separate glycerin after cooling, then carry out molecular distillation at 2 Pa and 140° C. to obtain 90% methyl linoleate. Take 150 milliliters of methyl ester, add 120 milliliters of methanol, 25-30 grams of caustic soda, and react at 155° C. for 4.5 hours under normal pressure.

[0046] In a 2-liter glass reactor, add 300 ml of water and 200 ml of ethanol to 145.3 g of sodium salt rich in conjugated linoleic acid. After fully stirring and dissolving, slowly add concentrated hydrochloric acid to adjust the pH to 9-10, slowly Add 75 milliliters of 40% calcium chloride aqueous solution dropwise, stir while adding dropwise, the kettle temperature is controlled at about 40°C, react for 2 hours, filter with suction, and obtain the product after the filter cake is vacuum-dried.

[0047] After analysis, the product is composed of the following component...

Embodiment 3

[0055] In 2.5 liters of Suaeda salsa seed oil, add 1.2 liters of methanol, 20 grams of KOH, react at 62°C for 2.5 hours, separate out glycerol after cooling; carry out molecular distillation at 6Pa, under the condition of 150°C to obtain 85% methyl linoleate; Add 150 ml of methyl ester, add 120 ml of methanol, 30 g of caustic soda, and react at 155° C. for 4.5 hours under normal pressure.

[0056]In a 2-liter glass reactor, add 300 ml of water and 200 ml of ethanol to 145.3 g of sodium salt rich in conjugated linoleic acid. After fully stirring and dissolving, slowly add concentrated hydrochloric acid to adjust the pH to 9-10, slowly Add 75 milliliters of 40% calcium chloride aqueous solution dropwise, stir while adding dropwise, the kettle temperature is controlled at about 40°C, react for 2 hours, filter with suction, and obtain the product after the filter cake is vacuum-dried.

[0057] After analysis, the product is composed of the following components by mass percentage: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com