Preparation method of quartz glass and quartz glass

A quartz glass and silica technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of inability to meet high-end market demands, inability to actively and precisely control hydroxyl groups, and uncontrollable hydroxyl content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

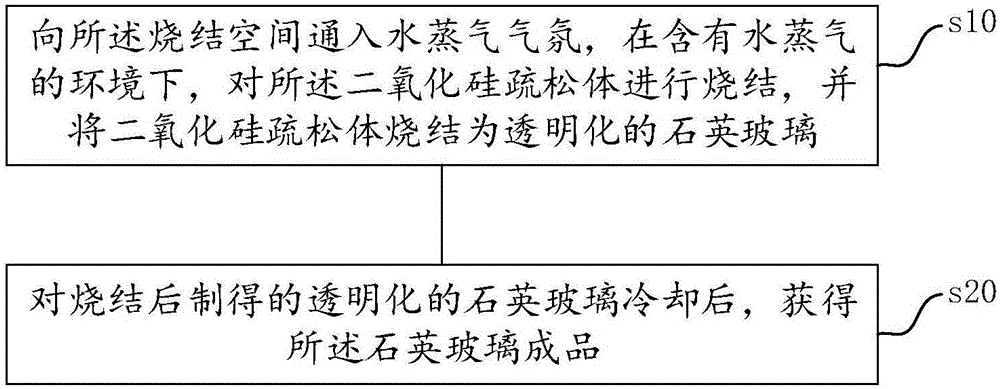

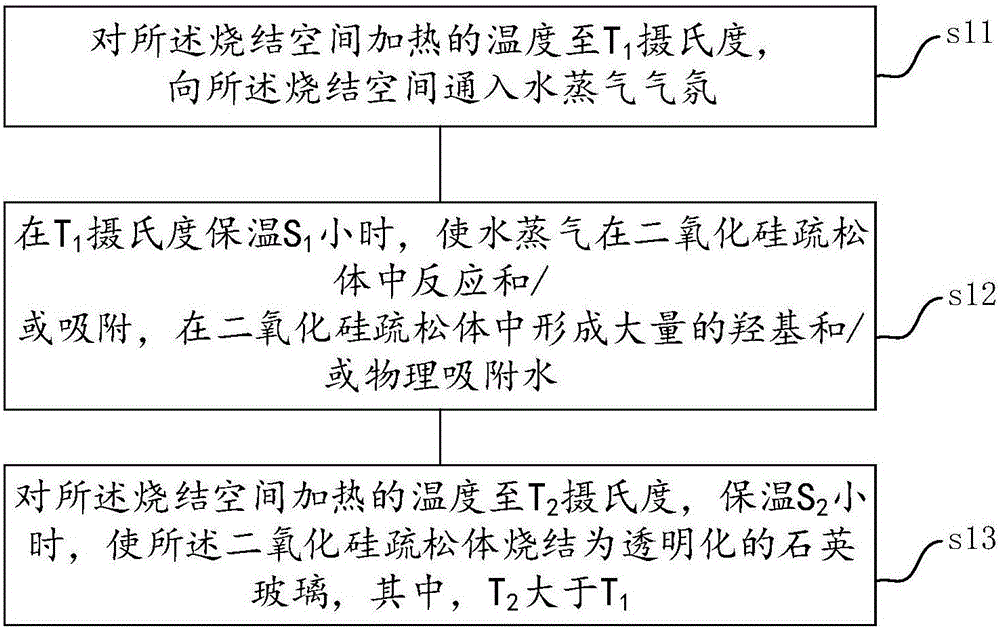

[0050] Such as figure 1 As shown, one embodiment of the present invention proposes a method for preparing quartz glass, which is used to prepare a silica soot body into a finished quartz glass product in a sintering space, wherein the silica soot body has pores; The sintering device for preparing quartz glass described in the following embodiment 2 is implemented, and for details, refer to the relevant expressions in the following embodiment 2. The methods include:

[0051] S10, introducing a water vapor atmosphere into the sintering space, sintering the silicon dioxide loose body in an environment containing water vapor, and sintering the silicon dioxide loose body into transparent quartz glass;

[0052] The inventors have obtained a technical solution for how to increase hydroxyl groups in the porous silica body through experiments: water vapor reacts and / or adsorbs in the porous silica body, forming a large number of hydroxyl groups and / or physical absorb water,

[0053]...

Embodiment 2

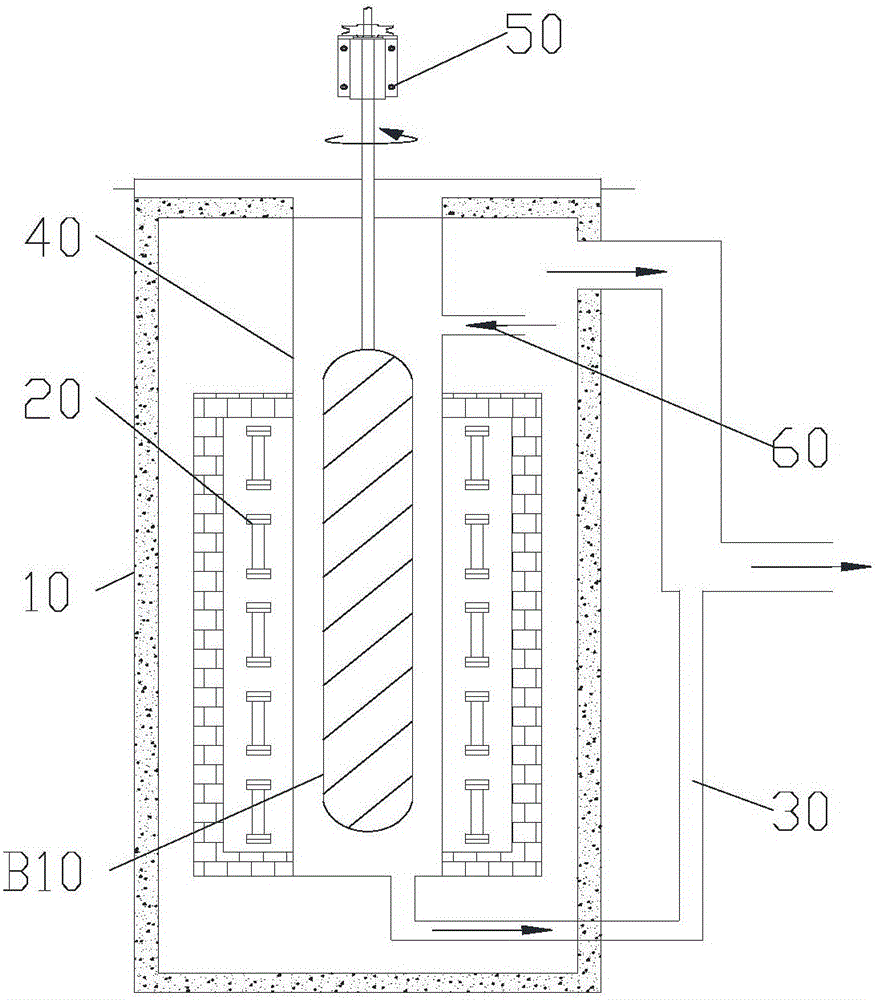

[0113] Embodiment 2 of the present invention provides a sintering device for preparing quartz glass, which is used for sintering a soot silica body to obtain a finished quartz glass product, wherein the soot silica body has pores; the soot silica body has a diameter of Can be more than 300mm; such as φ350mm, φ550mm, φ750mm, φ850mm, φ950mm.

[0114] The silicon dioxide loose body can be synthesized from silicon-containing raw materials through low-temperature chemical vapor deposition. The silicon dioxide loose body is a high-purity silicon dioxide loose body, and the silicon dioxide in the high-purity silicon dioxide loose body is The content is above 99.99%. Or the silica soot body is a doped silica soot body, and the doping elements are boron (B), aluminum (Al), fluorine (F), iron (Fe), titanium (Ti), cerium (Ce), At least one of calcium (Ca), magnesium (Mg), sodium (Na), potassium (K), barium (Ba), yttrium (Y), lanthanum (La), zirconium (Zr), and germanium (Ge).

[0115] ...

Embodiment 3

[0145] Such as Figure 5 As shown, a system for preparing quartz glass provided by Embodiment 3 of the present invention includes:

[0146] A low-temperature chemical vapor deposition device (not shown in the figure) is used for synthesizing silicon-containing raw materials through low-temperature chemical vapor deposition to obtain a silicon dioxide loose body, and the silicon dioxide loose body is a high-purity silicon dioxide loose body or a doped silicon dioxide Heterosilica soot body, wherein the content of silicon dioxide in the high-purity silica soot body is above 99.99%;

[0147] A sintering device 100 for preparing quartz glass, the sintering device for preparing quartz glass includes:

[0148] a furnace body, the furnace body has a sintering space for accommodating the silica loose body;

[0149] The furnace body also has a heater for heating the sintering space;

[0150] The furnace body is also equipped with a vacuum passage connecting the sintering space, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com