Preparation device and preparation method of rubber antioxidant TMQ

A technology of rubber anti-aging agent and preparation equipment, applied in the direction of organic chemistry, etc., can solve the problems of product application expansion, hindering market application, and long synthesis route of high-content anti-aging agent TMQ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

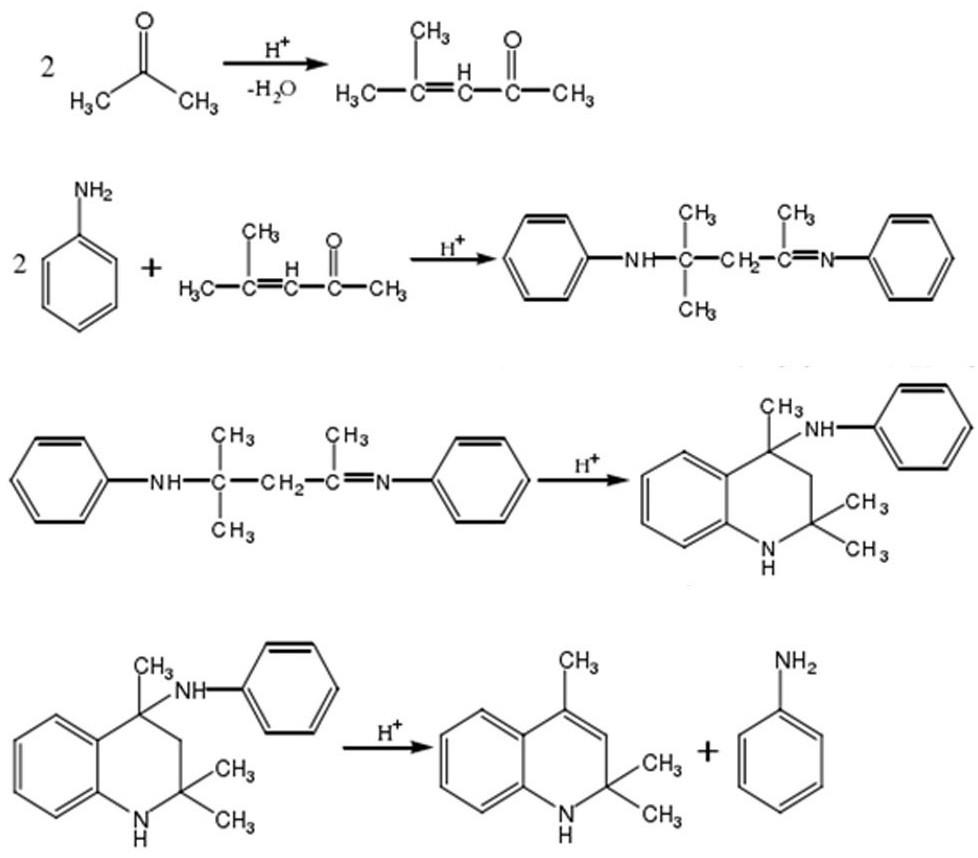

Method used

Image

Examples

preparation example Construction

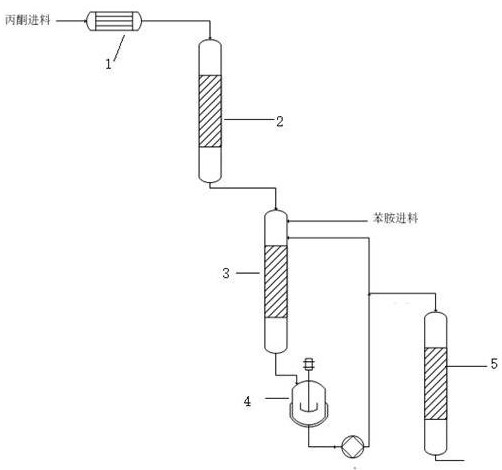

[0043] figure 1 A preparation device of a rubber antioxidant TMQ is shown, comprising an acetone preheater 1, an acetone polymerization tower 2, a semi-finished product synthesis tower 3, a semi-finished product receiving kettle 4 and a reaction kettle 5 connected in sequence;

[0044] The semi-finished product synthesis tower is provided with an aniline feed port; the acetone polymerization tower is provided with a basic resin, and the semi-finished product synthesis tower is provided with an acidic resin; the acetone preheater, the acetone polymerization tower, The semi-finished product synthesis tower, the semi-finished product receiving kettle, and the reaction kettle are all provided with heaters.

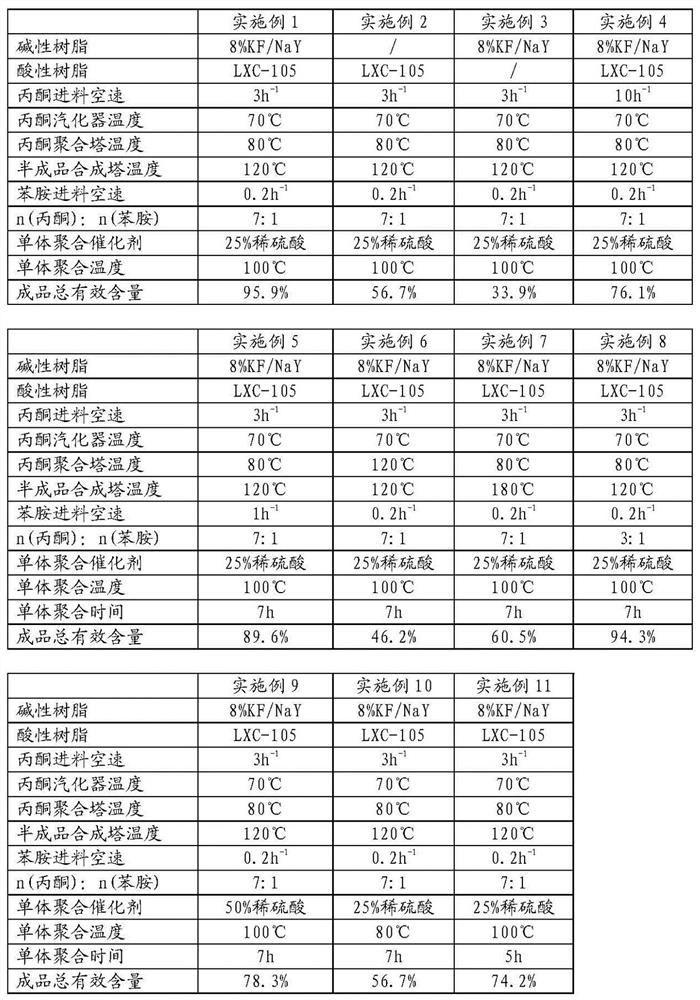

Embodiment 1

[0045] Embodiment 1: a method for preparing rubber antioxidant TMQ using the described preparation device of rubber antioxidant TMQ, comprising the following steps: (1) adding 8% KF / NaY resin catalyst to the acetone polymerization tower, and adding 8% KF / NaY resin catalyst to the semi-finished product. Xi'an Lanxiao LXC-105 high temperature resistant and strong acid cation exchange resin was added into the synthesis tower, and the mass ratio of the two catalysts was controlled to be 0.29:1; the heating medium of the acetone vaporizer was turned on and the temperature was raised to 70°C, and the heater of the acetone polymerization tower was turned on and the temperature was raised. to 80°C, turn on the semi-finished synthesis tower heater and raise the temperature to 120°C.

[0046] (2) First inject 50% volume of aniline into the semi-finished product receiving kettle, turn on the circulating pump and the semi-finished product receiving kettle heater, preheat the aniline to 100...

Embodiment 2

[0052] Example 2: Compared with Example 1, only the acetone polymerization tower is not filled with catalyst, and other conditions remain unchanged. In the reaction process, since there is no catalyst to catalyze the selective polymerization of acetone, acetone basically does not react during the heating process, and various reactions occur with aniline under the action of an acidic catalyst, resulting in many by-products and a low effective content of the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com