Anhydrous cerium-doped lanthanum bromide and preparation method thereof

A technology of cerium lanthanum bromide and hydrogen bromide, which is applied in the field of deep processing of rare earth materials, can solve the problems of difficult preparation of high-purity lanthanum bromide and cerium bromide, difficulty in growing large-sized crystals, waste of energy and time, and achieve large-scale Large-scale mass production, low production cost, consistent effect of cerium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

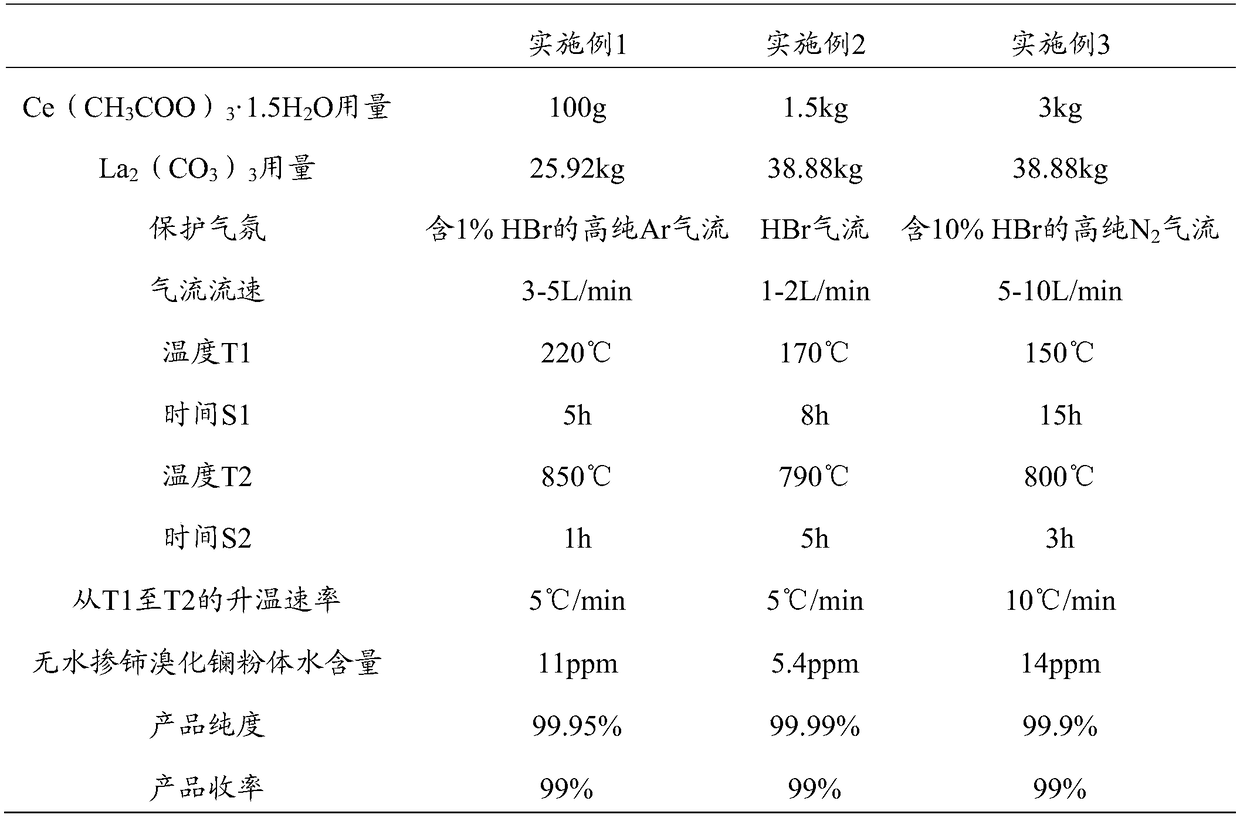

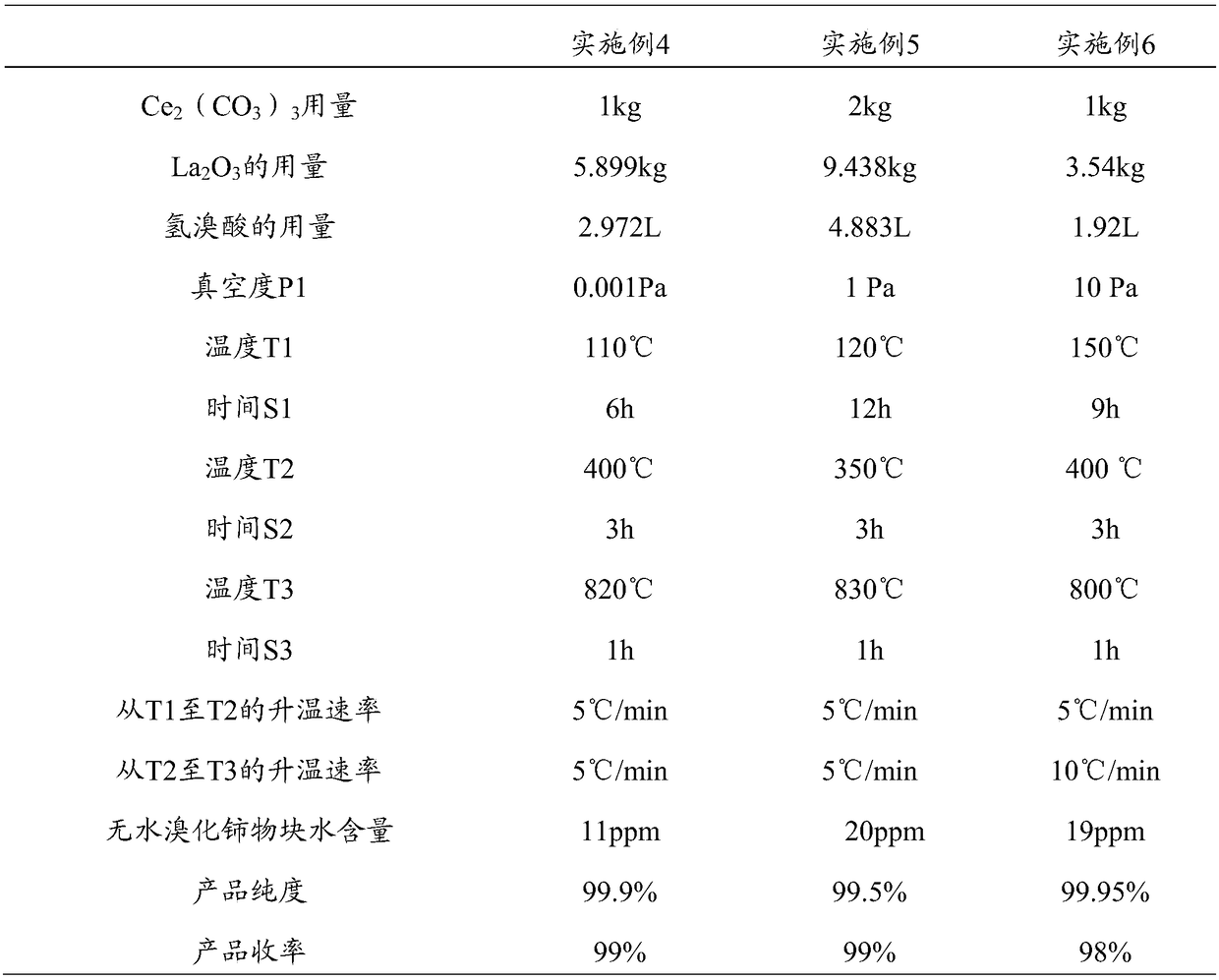

Examples

preparation example Construction

[0015] The preparation method of the anhydrous cerium-doped lanthanum bromide of the present invention specifically includes the following steps, and the whole preparation process is carried out under protective atmosphere or vacuum conditions.

[0016] (1) A cerium source and a lanthanum source are reacted in the presence of bromide ions.

[0017] Wherein, the cerium source may be cerium acetate hydrate or cerium carbonate. Preferably, the cerium acetate hydrate is cerium acetate with 1.5 to 3 crystal waters, more preferably, the cerium acetate hydrate is Ce(CH 3 COO) 3 1.5H 2 O, Ce(CH 3 COO) 3 2H 2 O or Ce(CH 3 COO) 3 ·3H 2 O. Lanthanum source can be lanthanum oxide (La 2 o 3 ) or lanthanum carbonate (La 2 (CO 3 ) 3 ). The mass ratio of cerium source and lanthanum source is (0.1-2):(0.5-50).

[0018] Wherein, the bromide ion is in the form of hydrogen bromide gas or hydrobromic acid aqueous solution, that is, the bromide ion is derived from hydrogen bromide g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com