Comprehensive treatment process of lithium slag

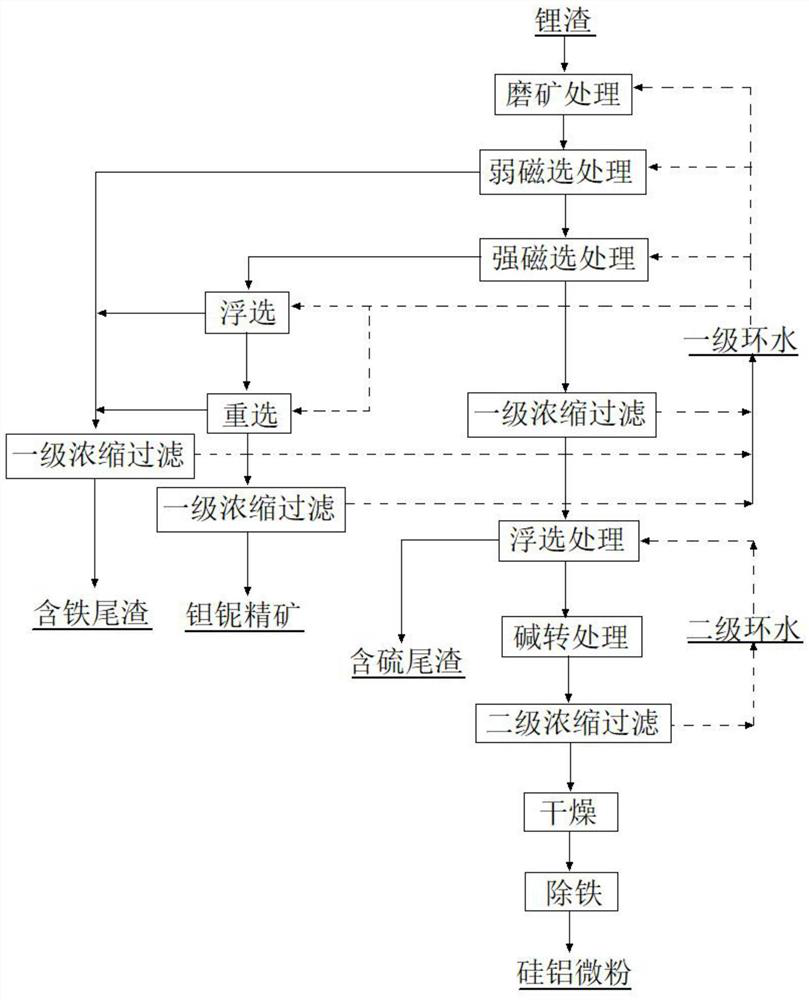

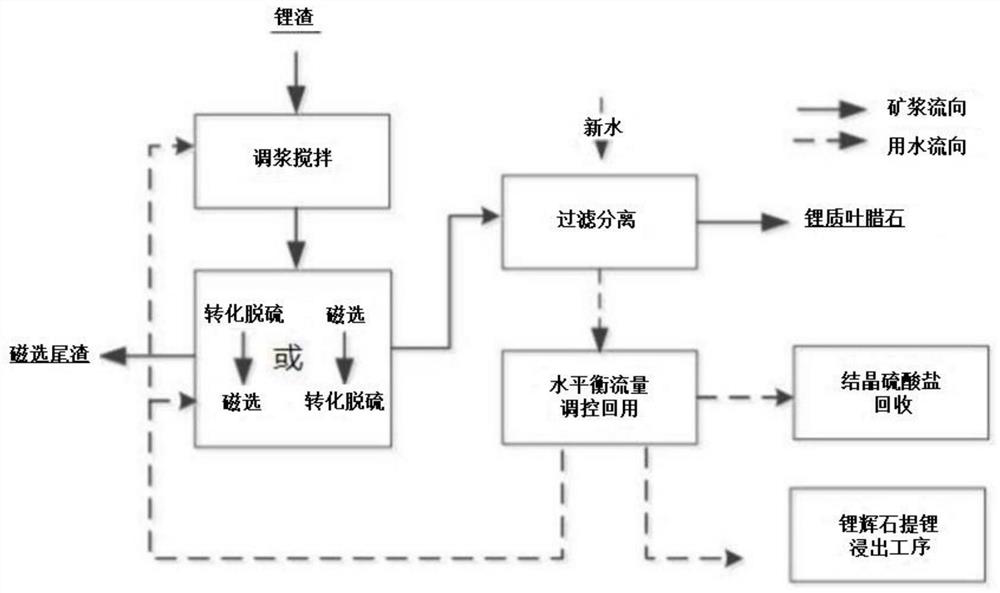

A comprehensive treatment and process technology, applied in the field of comprehensive utilization of waste residue generated after lithium extraction from lithium ore sulfuric acid process, can solve the problem of inability to truly achieve zero discharge of waste water, low replacement rate of natural pyrophyllite, and iron-containing silicon-alumina micropowder. In order to achieve the effect of realizing reuse, increasing the replacement rate and reducing the amount of replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Lithium slag (SiO 2 : 61.50%, Al 2 o 3 : 20.95%, SO 3 : 7.27%, Fe 2 o 3 : 0.81%, particle size: -45μm content: ≤45%), first use a ball mill to grind ore, and add dispersant water glass at the same time, grinding concentration: 35%; grinding products (particle size: -45μm proportion: ≥98% ) first go through weak magnetic separation to remove iron, and the magnetic field strength of weak magnetic separation is 0.3T; then use a two-stage high-field magnetic separator to remove iron, the rough magnetic field strength is 1.5T, and the sweeping magnetic field strength is 1.8T , The magnetic material slurry obtained by strong magnetic separation is flotation and re-election to obtain tantalum-niobium concentrate for sale. The magnetic material slurry obtained by weak magnetic separation and the tailings after flotation and gravity separation (flotation and gravity separation treatment of magnetic material slurry after strong magnetic separation) are mixed and dehydrated and...

Embodiment 2

[0087] Lithium slag (SiO 2 : 61.50%, Al 2 o 3 : 20.95%, SO 3 : 7.27%, Fe 2 o 3 : 0.81%, particle size: -45μm content: ≤45%), first use a ball mill to grind ore, and add dispersant water glass at the same time, grinding concentration: 40%; grinding products (particle size: -45μm proportion: ≥98% ) first go through weak magnetic separation to remove iron, and the magnetic field strength of weak magnetic separation is 0.3T; then use a two-stage high-field magnetic separator to remove iron, the rough magnetic field strength is 1.5T, and the sweeping magnetic field strength is 2.5T , The magnetic material slurry obtained by strong magnetic separation is flotation and re-election to obtain tantalum-niobium concentrate for sale. The magnetic material slurry obtained by weak magnetic separation and the tailings after flotation and gravity separation (flotation and gravity separation treatment of magnetic material slurry after strong magnetic separation) are mixed and dehydrated a...

Embodiment 3

[0090] For the lithium slag in embodiment 1, at first add water to adjust slurry, slurry concentration: 30%, add dispersant water glass simultaneously; The lithium slag slurry adopts weak magnetic field (magnetic field strength: 0.3T) magnetic separator to remove iron first, then adopts strong Magnetic field (magnetic field strength: 1.5T) magnetic separator to remove iron; after iron removal, the material is ground by ball mill, grinding concentration: 35%; the grinding product (particle size is -45μm proportion: ≥98%) is then used in a strong magnetic field (Magnetic field strength: 1.8T) Magnetic separator removes iron; Strong magnetic separation (Magnetic field strength: 1.8T) obtains tantalum and niobium concentrate for sale after flotation and gravity separation. The magnetic material slurry obtained by weak magnetic separation and the tailings after flotation and gravity separation (flotation and gravity separation treatment of magnetic material slurry after strong magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com