Preparation method of low-dysprosium corrosion-resistant sintering neodymium iron boron

A NdFeB, corrosion-resistant technology, applied in the field of magnetic material preparation, can solve the problems of affecting corrosion resistance, easy to change the electrochemical corrosion potential of grain boundary phase, etc., and achieve the effect of optimizing corrosion resistance and effective content control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

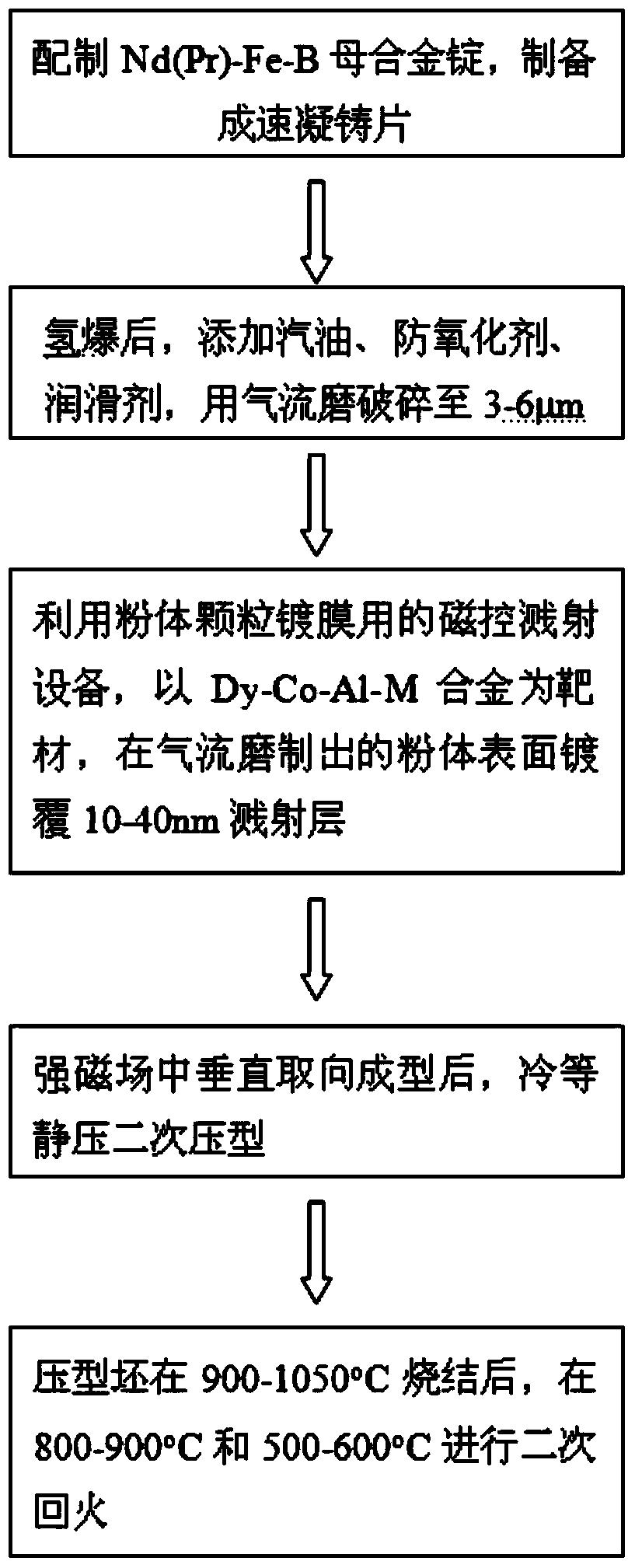

Method used

Image

Examples

Embodiment 1

[0019] 1. Prepare a master alloy ingot, the atomic percentage of which is: Nd: 9.0%, Pr: 3.0%, Fe: 81.5%, B: 6.5%, and use the vacuum induction quick-setting casting technology to prepare the master alloy quick-setting casting.

[0020] 2. After the master alloy quick-setting cast sheet is crushed by hydrogen explosion, add 0.5% of gasoline, 3.0% of special antioxidant and 0.1% of lubricant to the powder, mix well, and place in the air flow It is further crushed in the mill to make a powder with an average particle size of 6 μm.

[0021] 3. The powder made by jet milling is placed on the rolling sample stage of the magnetron sputtering equipment used for powder particle coating. Select the alloy target, its atomic percentage composition is: Dy: 80%, Co: 15%, Al: 5%; after the magnetron sputtering system is evacuated, the target material is sputtered on the rolling sample stage in an argon atmosphere On the powder falling with gravity, the average thickness of the sputtered la...

Embodiment 2

[0026] 1. Prepare a master alloy ingot, the atomic percentage of which is: Nd: 13.5%, Fe: 80.2%, B: 6.3%, and use the vacuum induction quick-setting casting technology to prepare the master alloy quick-setting casting.

[0027] 2. After the master alloy quick-setting cast sheet is crushed by hydrogen explosion, add 1.0% of gasoline, 0.5% of special antioxidant and 0.05% of lubricant to the powder, mix well, and place in the air flow It is further crushed in the mill to make a powder with an average particle size of 5 μm.

[0028] 3. The powder made by jet milling is placed on the rolling sample stage of the magnetron sputtering equipment used for powder particle coating. Select the alloy target, its atomic percentage composition is: Dy: 60.0%, Co: 25.0%, Al: 10.0%, Ga: 5.0%; after the magnetron sputtering system is evacuated, the target components are sputtered in an argon atmosphere Sputtered on the powder falling with gravity in the rolling sample stage, the average thickne...

Embodiment 3

[0033] 1. Prepare a master alloy ingot, the atomic percentage of which is: Nd: 12.5%, Fe: 80.8%, B: 6.7%, and use the vacuum induction quick-setting casting technology to prepare the master alloy quick-setting casting.

[0034] 2. After the master alloy quick-setting cast sheet is crushed by hydrogen explosion, add 1.0% of gasoline, 1.5% of special antioxidant and 0.1% of lubricant to the powder, mix well, and place in the air flow It is further crushed in the mill to make a powder with an average particle size of 4 μm.

[0035] 3. The powder made by jet milling is placed on the rolling sample stage of the magnetron sputtering equipment used for powder particle coating. Select the alloy target, its atomic percentage composition is: Dy: 40.0%, Co: 20.0%, Al: 30.0%, Cu: 2.0%, Nb: 3.0%, Ga: 5.0%; after the magnetron sputtering system is vacuumed, In an argon atmosphere, the target material components are sputtered on the powder falling with gravity in the rolling sample stage, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic coercive force | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

| Maximum energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com