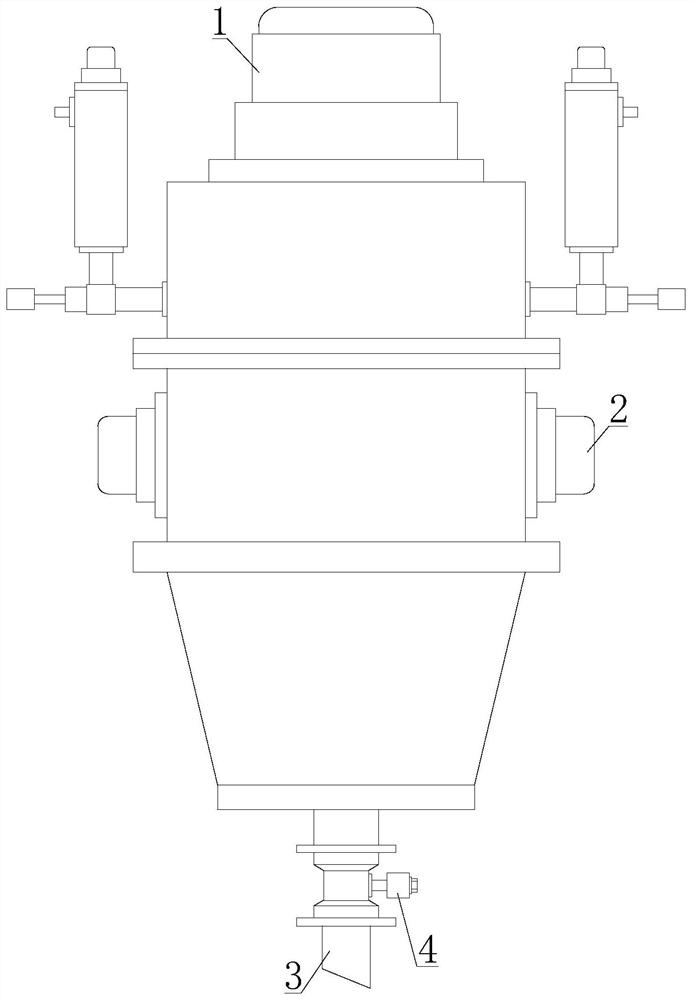

Mixing and blending device for water-borne wood paint production and implementation method of mixing and blending device

A water-based wood lacquer, mixing and blending technology, applied in the direction of chemical instruments and methods, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problem of excessive addition of ingredients, affecting the quality of water-based wood lacquer finished products, and the amount of ingredients added cannot be obtained Effective control and other issues to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

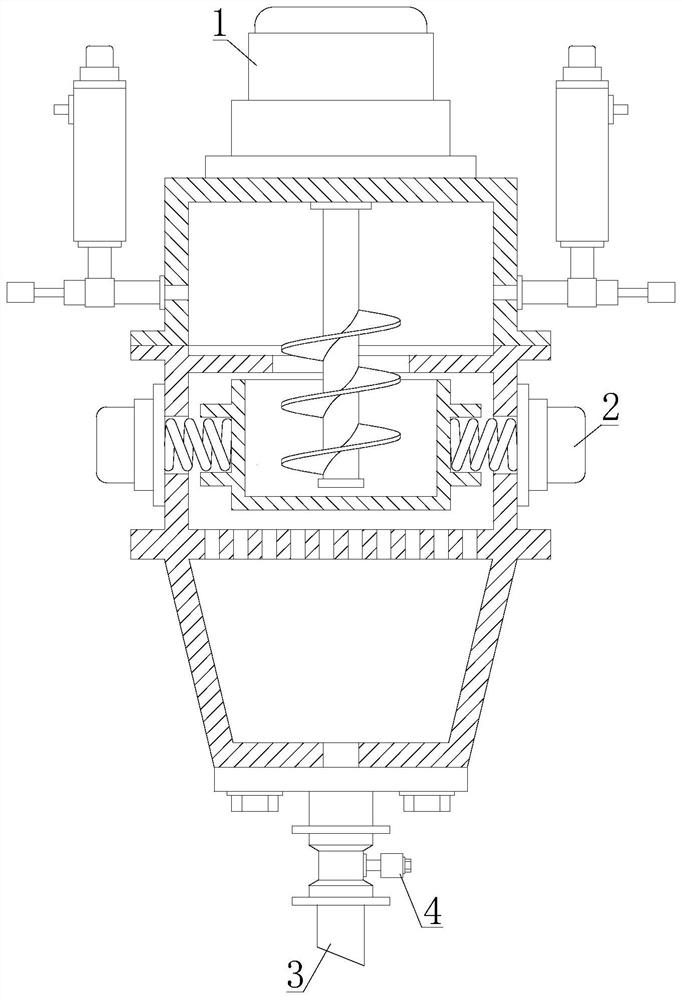

[0032] In order to better demonstrate the implementation process of the mixing and blending device for the production of water-based wood lacquer, this embodiment now proposes an implementation method of the mixing and blending device for the production of water-based wood lacquer, including the following steps:

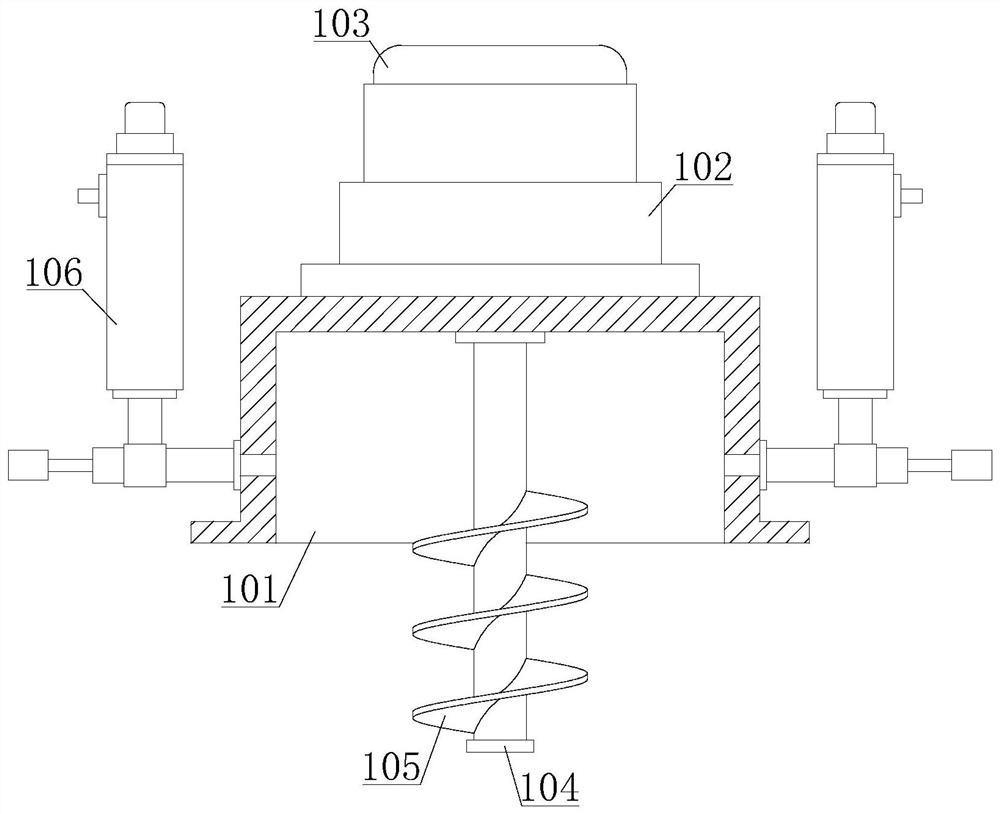

[0033] Step 1: Move the pushing head 10610 in the batching assembly 106 to the right below the feeding folded tube 1067, and use the pushing head 10610 to seal the mixing tube 1061;

[0034] Step 2: Drive the blending shaft 1064 and blending blade 1065 by the driving motor 1063 on the top of the stirring material pipe 1061 to stir the ingredients evenly;

[0035] Step 3: Move the pushing head 10610 to the lower right side of the feeding folded tube 1067, and then push forward, use the pushing head 10610 to push the ingredients flowing into the feeding folded tube 1067 into the mixing assembly 2, and pass through the deflector 23 and through hole 24, finally enter in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com