High-resistance water-based metal matte stoving varnish for computer case and preparation method of high-resistance water-based metal matte stoving varnish

A computer case, high-resistance technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of chemical resistance gap and harshness, and achieve good recoatability, strong adhesion, and excellent sag resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] A preparation method of the above-mentioned high-resistance water-based metal matte baking varnish for a computer case, comprising the following steps:

[0065] a. Preparation of water-based pigment and filler intermediates

[0066] According to the formula of the water-based pigment and filler intermediate, add water, dispersant, defoamer 1, wetting agent, superfine barium sulfate, anti-rust pigment, coloring pigment, anti-settling agent, ethylene glycol and others into the dispersing tank in turn. Components, high-speed dispersion for 30-50min, high-speed dispersion speed is 1200-1500r / min, sampling and testing, if the slurry fineness is ≤20μm;

[0067] b. Preparation of high-resistance water-based metal matte paint

[0068] Add epoxy-modified hydroxypropyl dispersion, water-based acrylic-modified polyurethane resin, neutralizer, cosolvent, water-based pigment and filler intermediate, defoamer 2, fluorocarbon surfactant, partial methyl etherification into the dispers...

Embodiment

[0070] The present invention will be further described below in conjunction with specific embodiments, but not limited thereto.

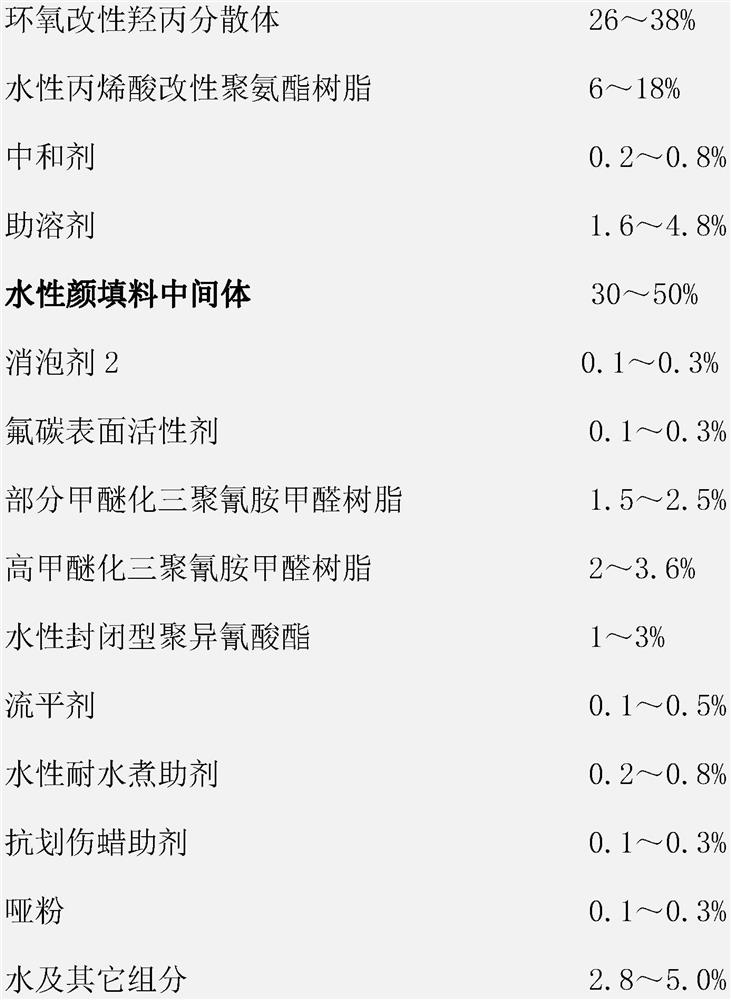

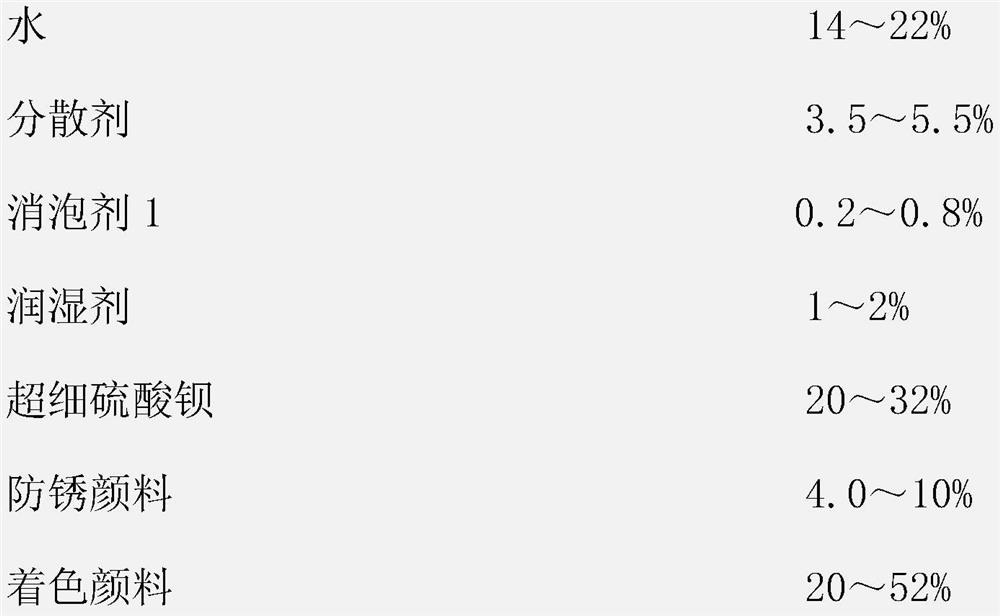

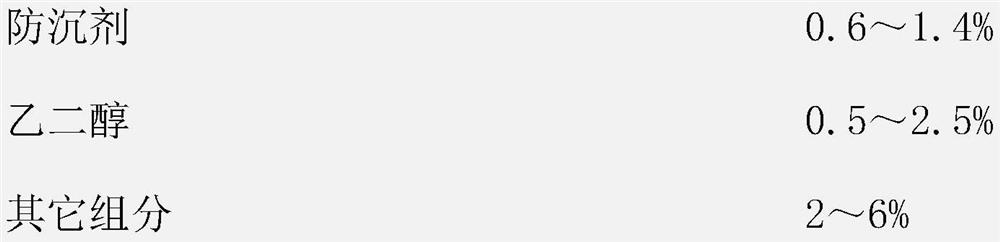

[0071] In this specific embodiment, Examples 1 to 5 are set to prepare the high-resistance water-based metal matte baking paint for computer chassis, wherein the formula of the water-based pigment and filler intermediate is shown in Table 1, and the formula of the main paint is shown in Table 2. The formula composition of Table 1 and Table 2 is calculated in terms of raw material mass percentage (%):

[0072] Table 1 The formula of water-based pigment and filler intermediate (unit: %)

[0073]

[0074]

[0075] Table 2 Main paint formula composition (unit: %)

[0076]

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com