Erbium strengthened magnesium-lithium alloy and preparation method thereof

A technology of magnesium-lithium alloys and alloying elements, applied in the field of magnesium-lithium alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

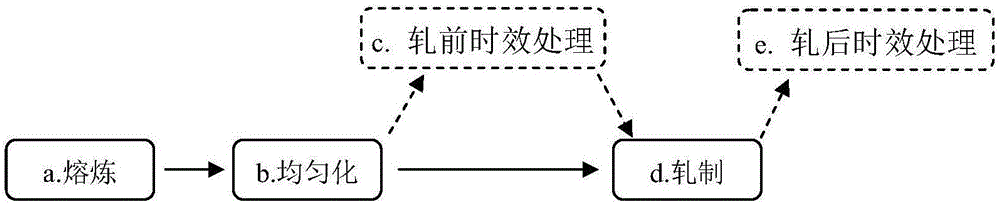

Method used

Image

Examples

Embodiment 1

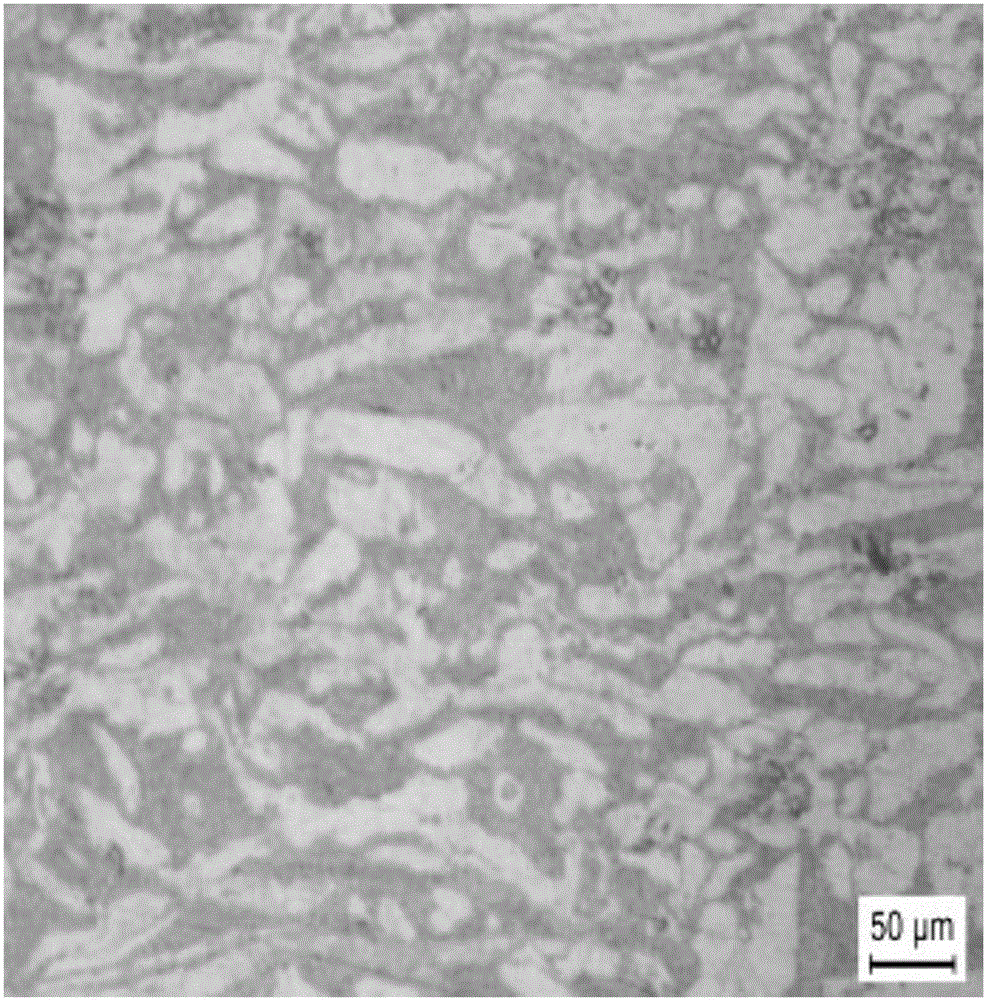

[0039] This embodiment is an erbium-strengthened magnesium-lithium alloy and its preparation method. The chemical composition is: Li: 8.21%, Al: 3.12%, Er: 2.94%, and the rest is Mg and unavoidable impurities. The homogenization treatment temperature is 240°C, and the treatment time is 2h. The aging temperature before rolling is 200°C, the holding time is 4h, and air-cooled to room temperature. The rolling temperature is 320°C, rolling 5 passes, with an average reduction of 27% each time, and a total reduction of 80%. No post-rolling aging treatment. Its mechanical properties are significantly improved, and its yield strength, tensile strength and elongation are respectively 9.2%, 19.2% and 20% higher than those of the Mg-Li-Al alloy. Metallographic photos see figure 2 , the mechanical properties of alloy materials see Figure 5 Table 1.

Embodiment 2

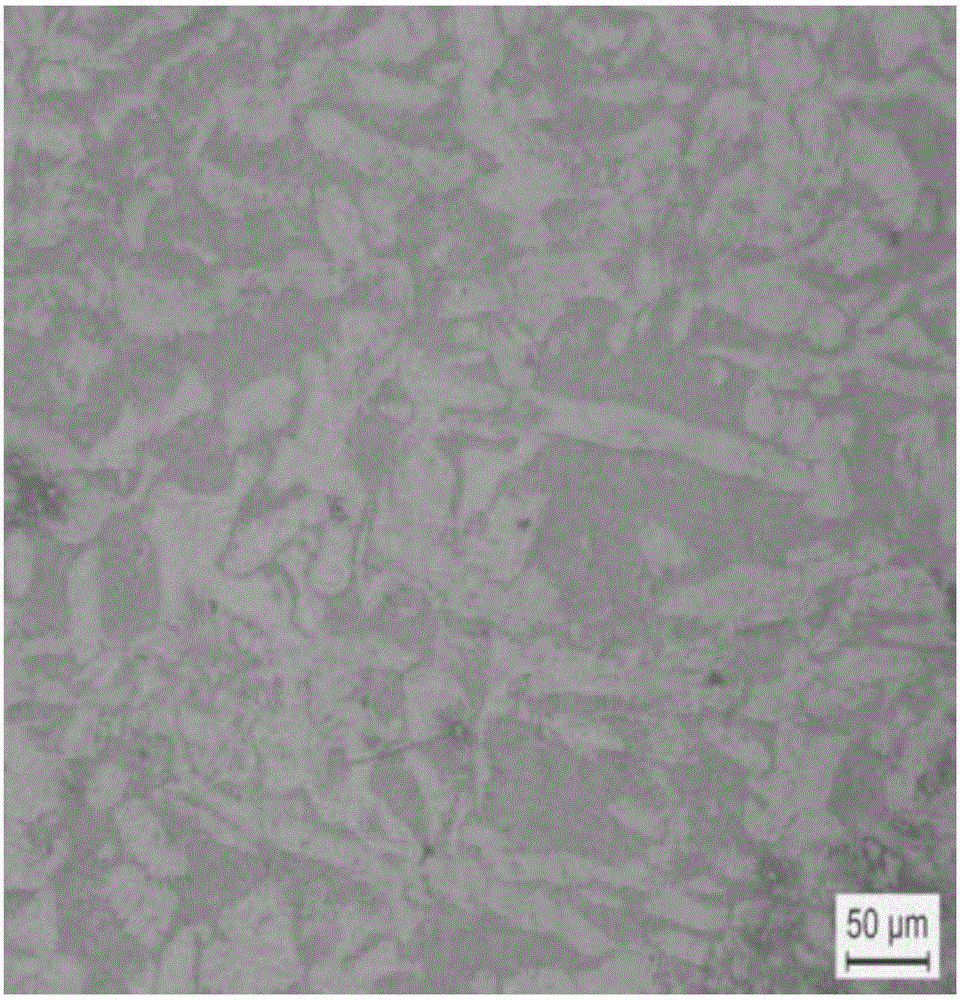

[0041] This embodiment is an erbium-strengthened magnesium-lithium alloy and its preparation method. The chemical composition is: Li: 8.21%, Al: 3.12%, Er: 2.94%, and the rest is Mg and unavoidable impurities. The homogenization treatment temperature is 240°C, and the treatment time is 2h. The aging temperature before rolling is 200°C, the holding time is 4h, and air-cooled to room temperature. The rolling temperature is 320°C, rolling 5 passes, with an average reduction of 27% each time, and a total reduction of 80%. The post-rolling aging treatment temperature is 180°C, the treatment time is 8h, and air-cooled to room temperature. Its mechanical properties are significantly improved, and its yield strength, tensile strength and elongation are respectively 11.3%, 23.9% and 1.3% higher than those of the Mg-Li-Al alloy. Metallographic photos see image 3 , the mechanical properties of alloy materials see Figure 5 Table 1.

Embodiment 3

[0043]This embodiment is an erbium-strengthened magnesium-lithium alloy and its preparation method. The chemical composition is: Li: 8.21%, Al: 3.12%, Er: 2.94%, and the rest is Mg and unavoidable impurities. The homogenization treatment temperature is 240°C, and the treatment time is 2h. The aging temperature before rolling is 200°C, the holding time is 4h, and air-cooled to room temperature. The rolling temperature is 320°C, rolling 5 passes, with an average reduction of 27% each time, and a total reduction of 80%. The post-rolling aging treatment temperature is 180°C, the treatment time is 8h, and the quenching water is cooled to room temperature. Its mechanical properties are significantly improved, and its yield strength, tensile strength and elongation are respectively 16.2%, 28.7% and 39.1% higher than those of the Mg-Li-Al alloy. Metallographic photos see Figure 4 , the mechanical properties of alloy materials see Figure 5 Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com