Combination vibration sieve

A vibrating sieve and coarse sieve technology, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems of high water content requirements of lump ore, easy blockage of sieve holes, and large relative flow rate of the lower sieve, so as to improve the utilization factor of the blast furnace , Improve screening efficiency and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

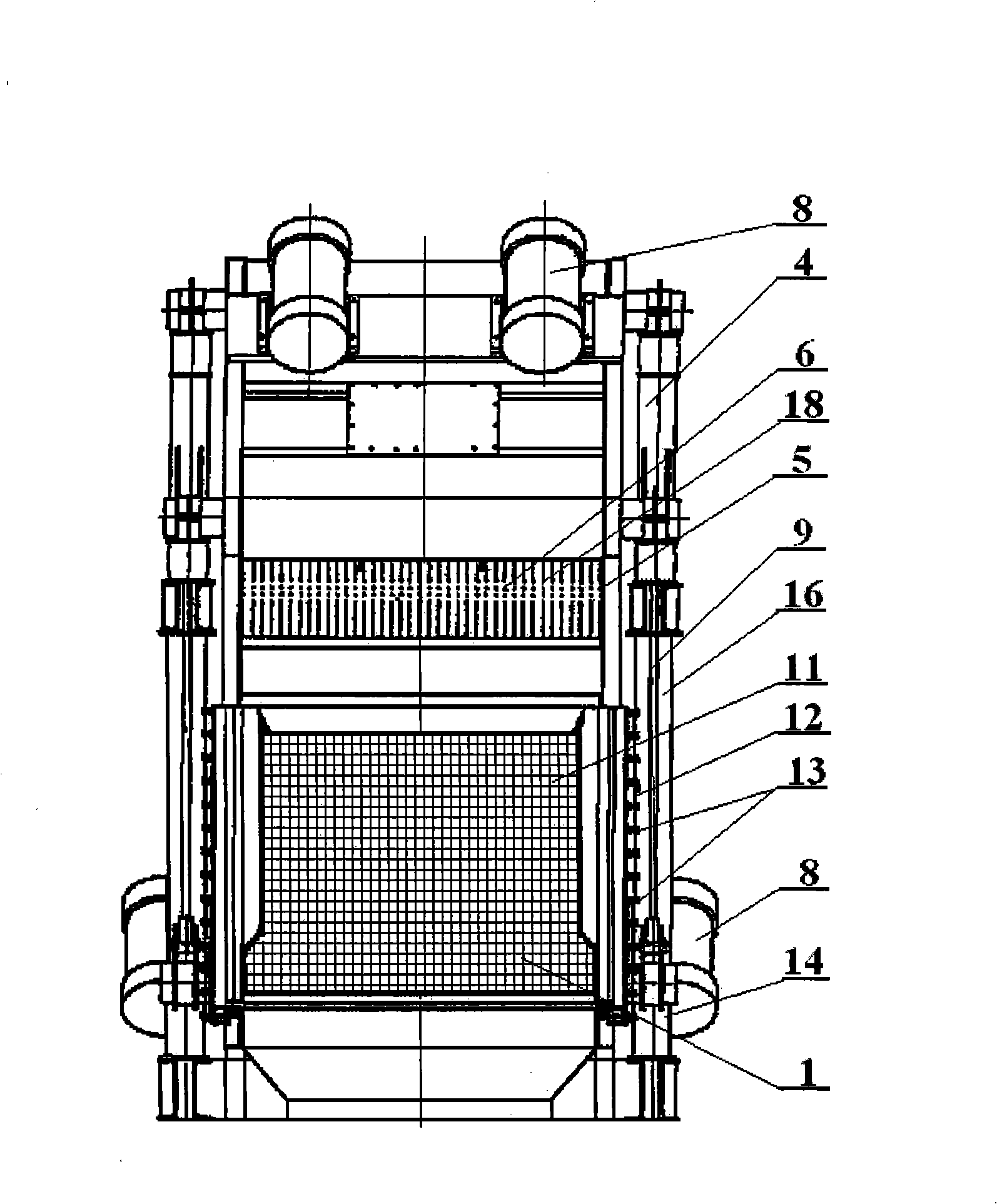

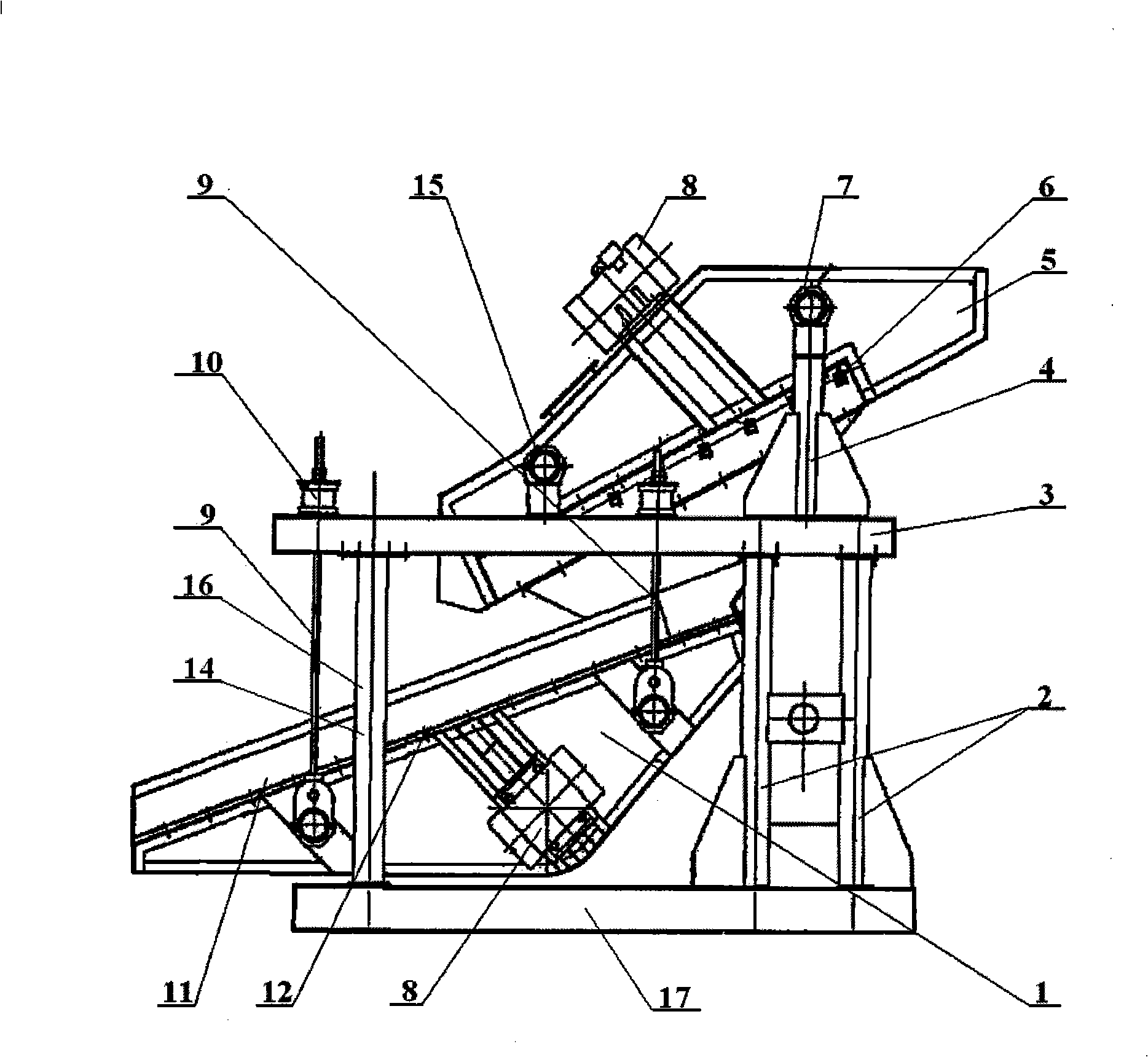

[0038] The technical scheme of the screening structure on the fine vibrating screen 1: the screening structure on the fine vibrating screen 1 is a fine sieve plate 11, the material of the fine sieve plate 11 is polyurethane, and a steel wire layer is arranged in the interlayer , making it a three-layer structure from top to bottom. The purpose of using the polyurethane material is to make the fine sieve plate 11 have good flexibility and strength; the purpose of using the steel wire layer is to strengthen the strength of the fine sieve plate 11 .

[0039] SF-150×330-T can be selected as the sieve type of fine vibrating sieve 1, and the sieving inclination angle can be adjusted. For the adjustment method, refer to Embodiment 6 and Embodiment 7. The amplitude of the fine vibrating screen 1 is: 2.5-12cm; the single point dynamic load of the fine vibrating screen 1: 26KN; the processing capacity is ≥100T / h.

Embodiment 2

[0041] The upper and lower layers of the fine sieve plate 11 are installed in such a way that the sieve holes of each layer are arranged in a dislocation manner.

[0042] The sieve holes of the upper and lower layers are arranged in a dislocation, so that the sieve holes of each layer of mesh can be one size larger, which is not easy to cause blockage; ; Simultaneously, because the fine sieve plate 11 has certain elasticity, under the effect of vibration, the upper and lower sieves can be staggered with each other, so as to clean up the blockage.

Embodiment 3

[0044] The sieve frame body used to connect the fine sieve plate 11 around the fine sieve plate 11 is a steel frame 12, and the two sides of the fine sieve plate 11 are connected to the steel frame 12 by tension springs 13. .

[0045] Tension springs 13 are installed between both sides of the single-layer fine sieve plate and the steel frame 12 to keep the surface of the fine sieve flat, avoid the fall of the fine sieve plate 11, and improve the screening efficiency of lump ore.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com