Processing method of high-grade tobacco expansion shreds

A processing method and technology of shredded tobacco, which is applied in the field of processing high-grade tobacco expanded shreds, can solve the problems of obvious dryness of smoke, less aroma, and poor internal quality, so as to reduce the amount of tar and harmful components released, and lose flavor components Small, intrinsic quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

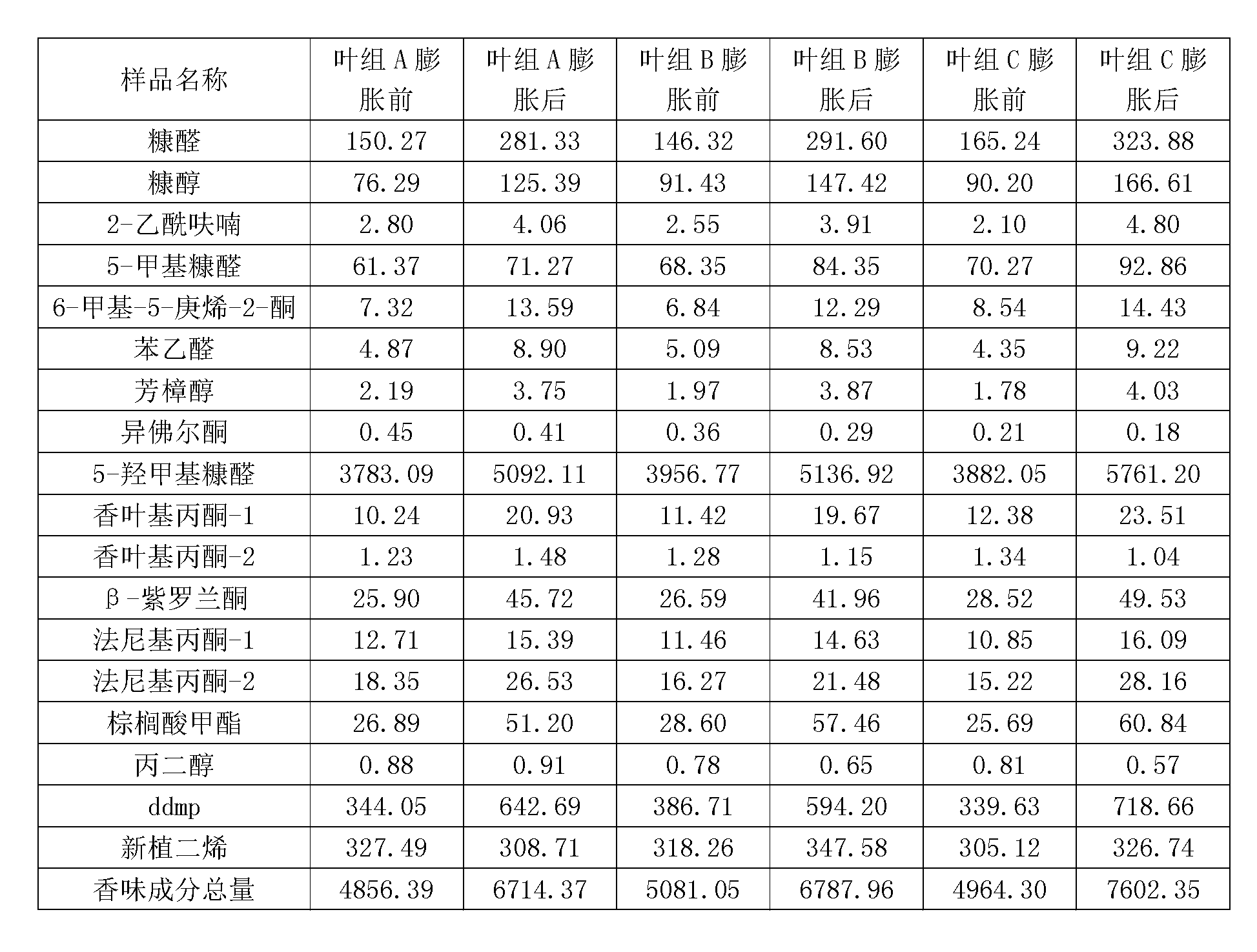

Embodiment 1

[0023] Leaf group formula A composed of top and medium tobacco leaves, the width of shredded tobacco after moistening and cutting is 0.8mm, and the shredded tobacco is treated with CO 2 The moisture content of the shredded tobacco is 20.1% after the expansion line is dampened once, and the shredded tobacco enters the CO 2 Dipping in a dipping tank, the dipping pressure is 2.8Mpa, the dipping time is 25 seconds, CO 2 The drainage time is 150 seconds, and the CO in shredded tobacco after impregnation 2 The content accounts for 3% by weight of shredded tobacco. After impregnation, the shredded tobacco is dried and expanded by the fluidized bed. The flow rate of the fluidized bed drying process is 2500kg / h (the so-called process flow rate is the flow rate of the shredded tobacco in the fluidized bed), and the temperature of the first zone of the fluidized bed is 100 0 C. The temperature in the second and third zones is normal temperature, the steam flow rate is 600 kg / h, and the...

Embodiment 2

[0026] Leaf group formula B composed of top and medium tobacco leaves, the width of shredded tobacco after moistening and cutting is 1.0 mm, and the shredded tobacco is treated with CO 2 The moisture content of the shredded tobacco is 22.6% once the expansion line is re-moisturized, and the shredded tobacco enters CO after the first re-moisture 2 Dipping in a dipping tank, the dipping pressure is 2.8Mpa, the dipping time is 35 seconds, CO 2 The drainage time is 240 seconds, and the CO in shredded tobacco after impregnation 2 The content accounts for 5% by weight of shredded tobacco. After impregnation, the shredded tobacco enters the fluidized bed for drying and expansion after preliminary loosening. 0 C, the temperature in the second and third zones is normal temperature, the steam flow rate is 750kg / h, and the moisture content of cut tobacco after fluidized bed drying and expansion is 12.5%. Then enter the flavoring machine to add characteristic spices.

[0027] The prep...

Embodiment 3

[0029] Leaf group formula C composed of top and medium tobacco leaves, the width of shredded tobacco after moistening and cutting is 1.1 mm, and the shredded tobacco is treated with CO 2 The moisture content of the shredded tobacco is 24.8% once the expansion line is dampened once, and the shredded tobacco enters the CO 2 Dipping in a dipping tank, the dipping pressure is 2.8Mpa, the dipping time is 60 seconds, CO 2 The drainage time is 320 seconds, and the CO in shredded tobacco after impregnation 2 The content accounts for 6% by weight of shredded tobacco. After the impregnated shredded tobacco is preliminarily loosened, it enters the fluidized bed for drying and expansion. The flow rate of the fluidized bed drying process is 2500kg / h, and the temperature of the first zone of the fluidized bed is 140 0 C, the temperature in the second and third zones is normal temperature, the steam flow rate is 850kg / h, and the moisture content of cut tobacco after fluidized bed drying and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com