Method for encapsulating LED with rotary glue and optical etching technology

A technology of light-emitting diodes and photolithography technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as low production efficiency, application restrictions, and difficulty in ensuring seamless bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

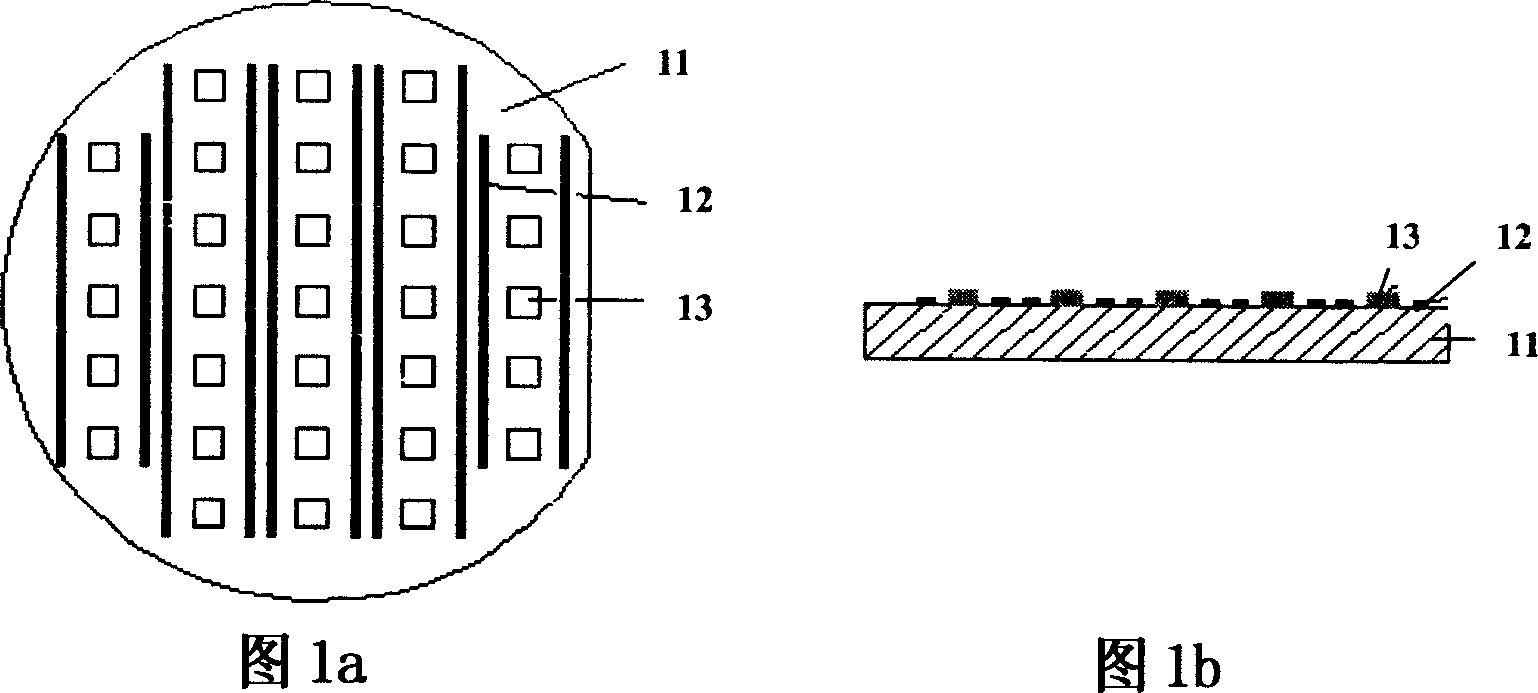

[0011] Referring to Fig. 1a and Fig. 1b, GaN blue light-emitting chips 13 and electrodes 12 are fabricated into an array on the chip substrate 11 by multi-layer epitaxy and photolithography and etching processes;

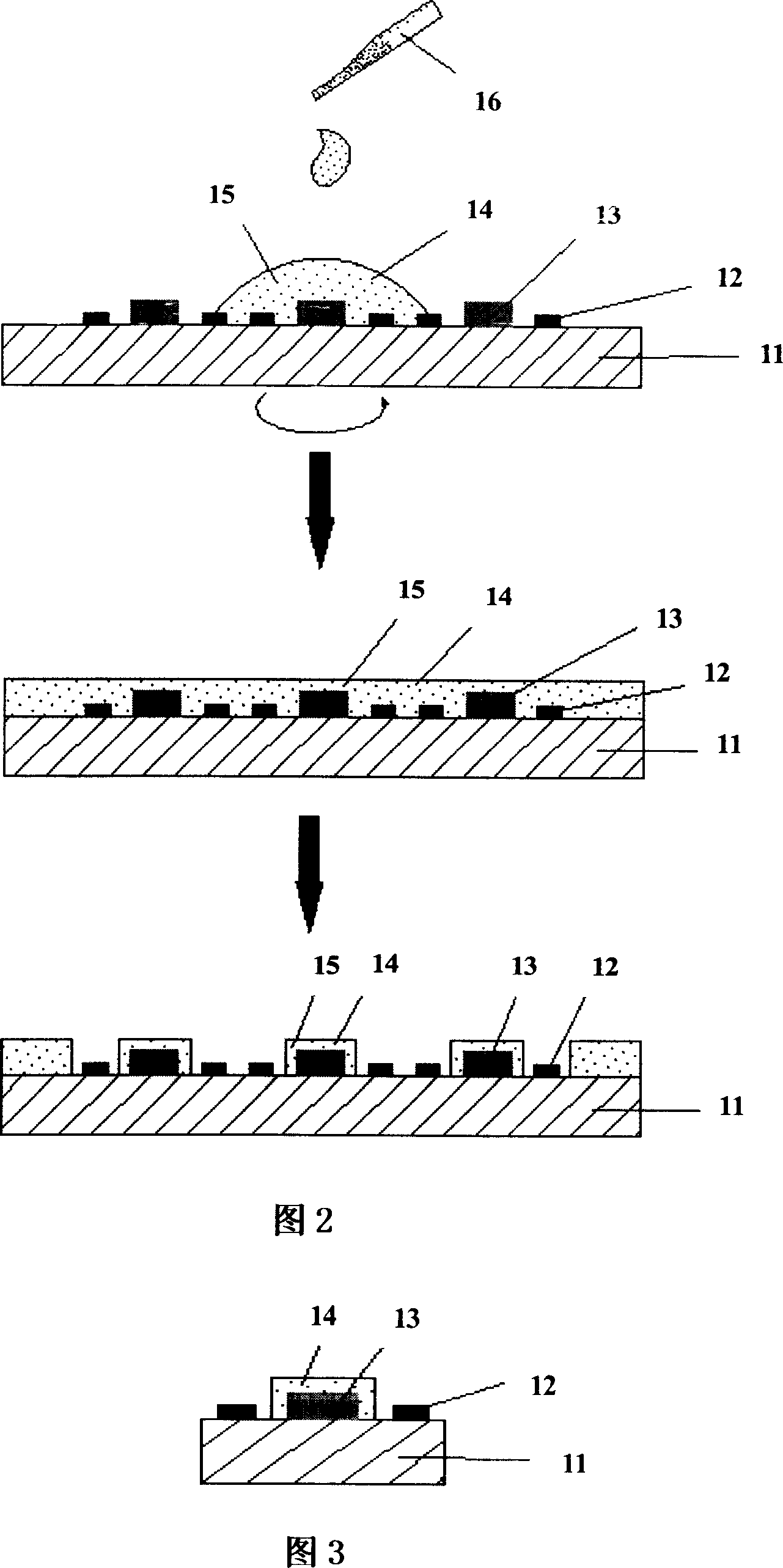

[0012] The present invention adopts glue-spinning and photolithography technology, and the glue-spinning process refers to dripping glue 14 containing fluorescent powder when the chip substrate 11 is rotating, so that the glue is evenly dispersed and coated on the chip substrate 11, and the blue-ray chip array containing GaN 13, a phosphor-containing adhesive layer 14 with a uniform thickness is formed on the surface of the chip substrate 11, and a white LED package is realized by photolithography, development, curing, and cutting processes. Referring to Fig. 2, its specific process steps are as follows:

[0013] 1) In the photolithography room, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com