Polyphenylene sulfide composite filament one-step method complete plant and production method

A technology of polyphenylene sulfide and composite filament, which is applied in the direction of conjugated synthetic polymer artificial filament, filament/thread forming, filament forming treatment, etc., which can solve the problem of high quality, high processing cost and uniformity In order to reduce the cost of raw materials, increase the production rate, and manage easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

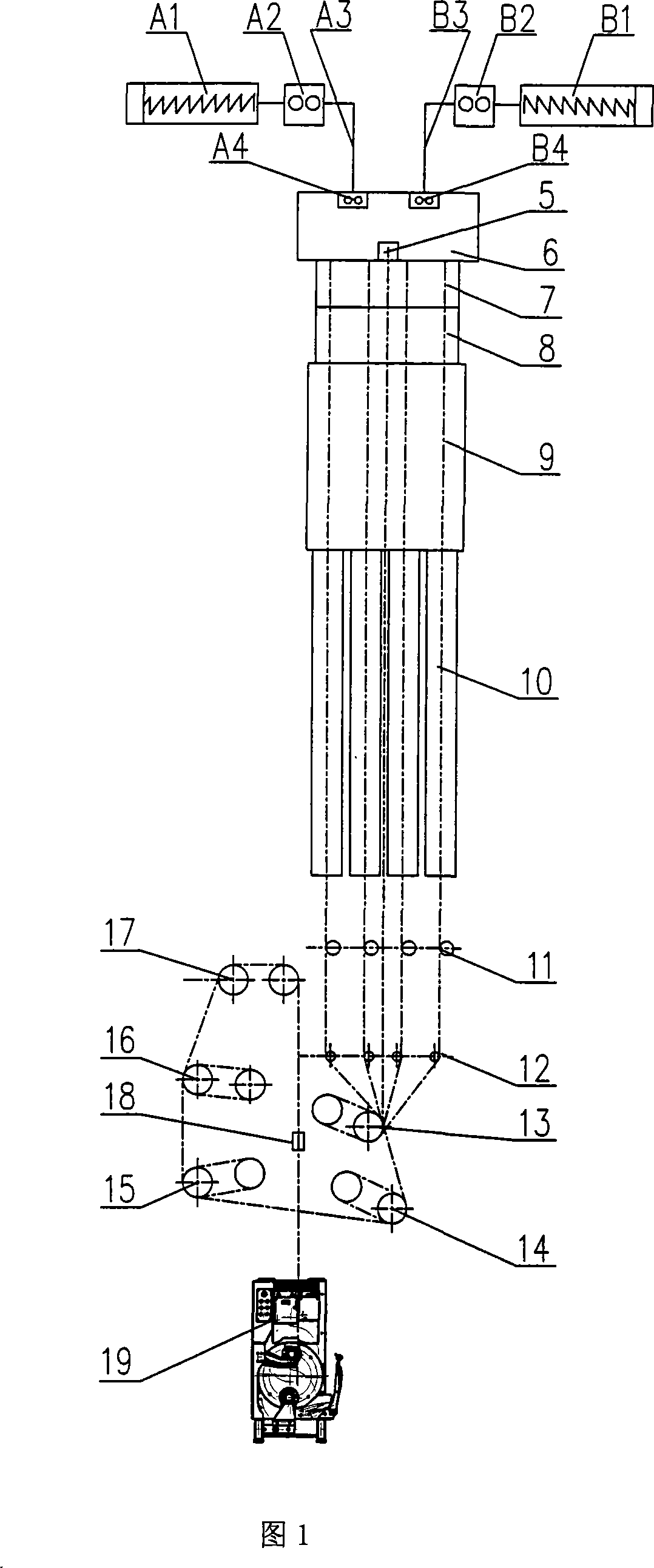

Method used

Image

Examples

Embodiment 1

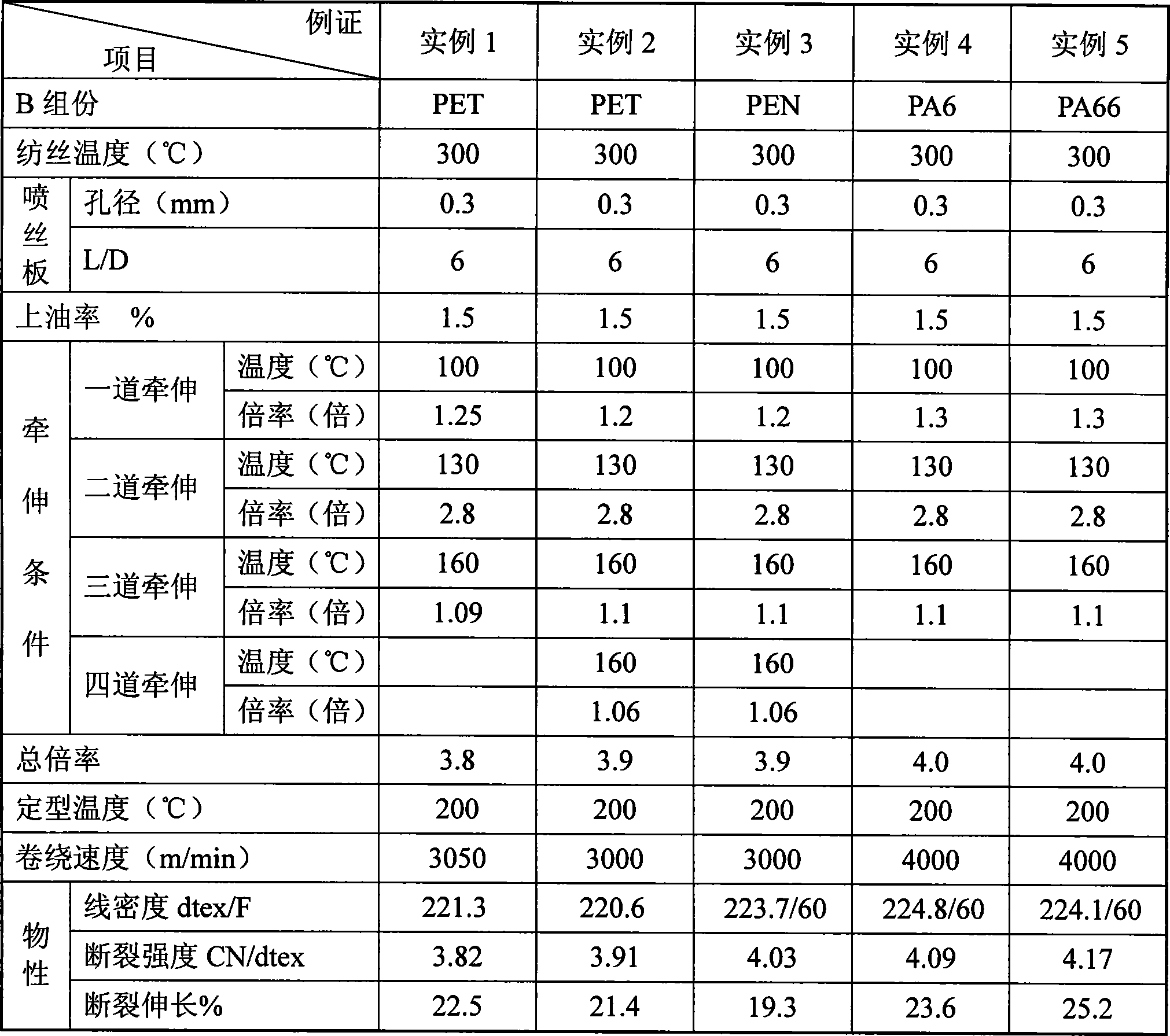

[0031]Component A adopts linear PPS slices with an MFR of 210g / 10min. In order to avoid the blockage of polyphenylene sulfide slices during the screw melt extrusion process, causing pressure fluctuations, oxidative degradation and crosslinking, etc., before melt spinning, Dry in known vacuum drum or pre-crystallization drying equipment, moisture content is 23PPM. When melting, the screw temperature is 280-325°C; for component B, PET chips with an intrinsic viscosity of 0.67 are used. After drying, the moisture content is 21PPM, and the screw temperature is 278-295°C when melting. The temperature of the composite box is controlled at 300°C, the spinneret hole diameter is 0.3mm, the length-to-diameter ratio (L / D) is 6, the number of spinneret holes is 60, the slow cooling zone is 10cm below the spinneret, and the slow cooling zone The temperature is 240°C; the wind temperature in the cooling zone is 25°C; the oiling rate is 1.5%; three draftings are used for drafting, the total ...

Embodiment 2

[0032] The spinning conditions of Example 2 are the same as in Example 1, except that four drafting processes are adopted during drafting, and the drafting conditions and physical property indexes are shown in Table 1.

Embodiment 3

[0033] Component A of Example 3 is the same as that of Example 1. Component B is PEN with a water content of 26PPM, and the screw temperature is 275-290°C during melting. The spinning and drawing winding conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com