III-group nitride light-emitting diode (LED) and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the complexity and uncertainty of the LED manufacturing process, improve crystal quality and uniformity of light emission, improve crystal quality, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

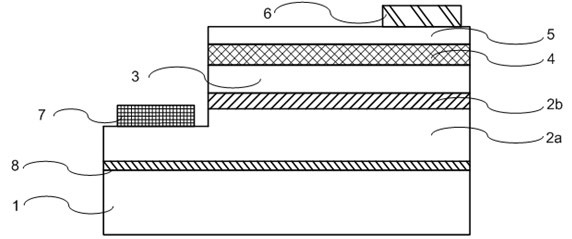

[0032] Such as figure 1 As shown, a III-nitride light-emitting diode includes a substrate 1 and a semiconductor epitaxial stack stacked on the substrate. The above-mentioned substrate 1 is made of sapphire (Al 2 o 3 ) material, the semiconductor epitaxial stack is made of aluminum gallium indium nitrogen (In x Ga y Al 1-x-y N, 0<=x<=1, 0<=y<=1) material formation. In order to solve the lattice mismatch problem between the semiconductor epitaxial stack and the substrate, a buffer layer 8 is provided between the semiconductor epitaxial stack and the substrate.

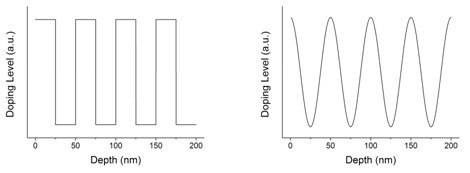

[0033] The semiconductor epitaxial stack includes an N-type layer 2, a light-emitting layer 3, and a P-type layer 4 from bottom to top. Part of the semiconductor epitaxial stack is etched to form an N-type layer mesa in the N-type layer 2. The N-type layer mesa N-type electrode 7 is arranged on it; P-type electrode 6 is arranged on the upper surface of the unetched part of P-type layer 4; The heterogeneous layer 2b, ...

Embodiment 2

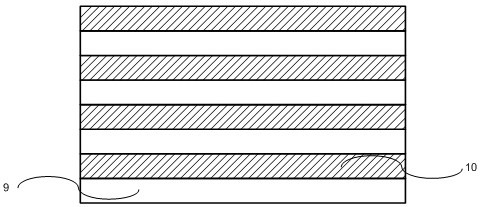

[0044] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the modulation doped layer 2b in the N-type layer 2 of the light-emitting diode of this embodiment is a gradient transition layer with a concentration, and the doping concentration of the uniform doped layer gradually decreases. for low doping concentration. The doping concentration is controlled by the flow rate of metal organic chemical vapor deposition equipment for impurities during epitaxial growth. The modulation doped layer 2 b is a doping linearly changing region with a thickness of 50 nm, and the closer to the light-emitting layer 3 , the lower the doping concentration. During the manufacturing process, the doping method can be changed to a non-linear monotonically decreasing form according to actual requirements, and the thickness of the modulation doping layer 2b can also be changed accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com