Patents

Literature

30results about How to "Improve adsorption and separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

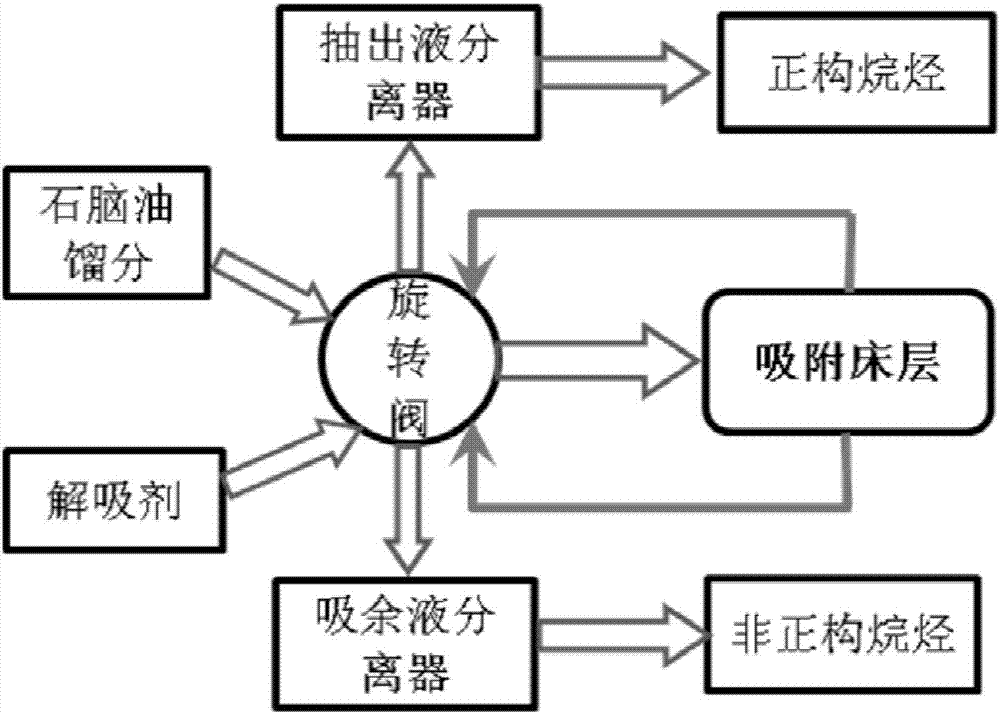

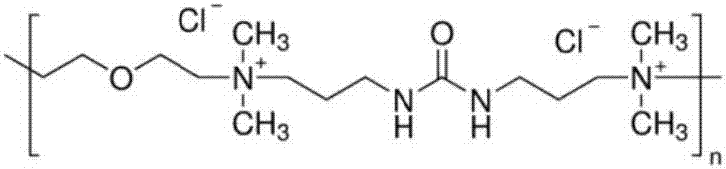

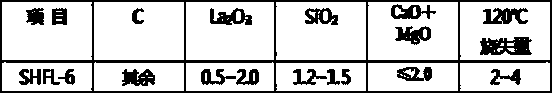

5A molecular sieve absorbent for adsorptive separation of distillate containing n-alkane and preparation method of 5A molecular sieve adsorbent

PendingCN106861614AAdsorption equilibrium time is shortImprove adsorption and separation efficiencyOther chemical processesHydrocarbon oils refiningIon exchangeMolecular sieve

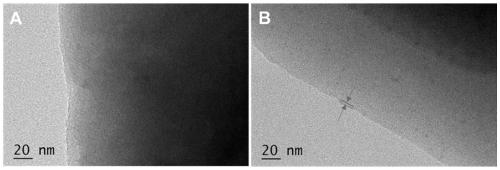

The invention discloses a 5A molecular sieve adsorbent for adsorptive separation of distillate containing n-alkane and a preparation method of the 5A molecular sieve adsorbent. The preparation method comprises the following steps: adding polyquaternary ammonium salt serving as a crystallization synthetic soft template agent into a sol system formed by mixing a silicon source with an aluminum source, and carrying out hydrothermal synthesis to obtain a hierarchically porous 4A molecular sieve with a microporous-mesoporous structure; after the 4A molecular sieve is subjected to soft template agent removal, carrying out roll forming on the treated 4A molecular sieve and a binder to obtain small balls with particle sizes of 0. 2 to 0.8mm; drying, roasting and then carrying out calcium ion exchange and activating to obtain the 5A molecular sieve adsorbent with the microporous-mesoporous structure, wherein the proportion of a 5A molecular sieve in the adsorbent is 90 to 97 weight percent, and the proportion of the binder is 3 to 10 percent. The preparation method of the adsorbent, provided by the invention, has the advantages that a diffusion coefficient of the n-alkane in the molecular sieve is remarkably improved while the synthesized hierarchically porous 5A molecular sieve maintains higher equilibrium adsorption capacity for the n-alkane, thereby increasing the rate of adsorptive separation.

Owner:CHINA CATALYST HLDG CO LTD

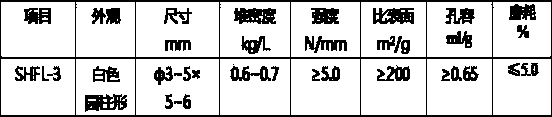

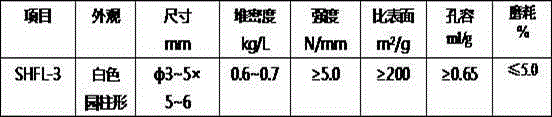

Special activated carbon for adsorption separation of chlorine gas and oxygen

ActiveCN103752270AImprove adsorption capacityImprove adsorption and separation efficiencyChlorine/hydrogen-chloride purificationOther chemical processesActivated carbonPhysical chemistry

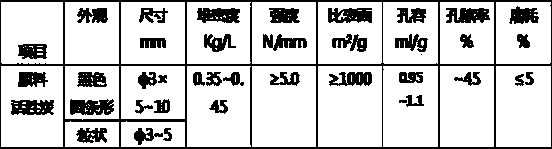

The invention discloses special activated carbon for adsorption separation of chlorine gas and oxygen. A product is prepared from activated carbon by the processes of dipping, drying and baking for decomposing in sequence. The special activated carbon has the physical properties that the bulk density is 0.40-0.45 kg / L, the strength is greater than or equal to 5.5N / mm, the specific surface is greater than or equal to 900m<2> / g, the pore volume is 0.9-1.0 ml / g, and the abrasion is smaller than or equal to 5%. By virtue of the special activated carbon, the related application performance such as the adsorption and separation efficiency and stability, the compression strength and the abrasion resistance quality uniformity of the chlorine gas and the oxygen are improved, and not only is the purity of the products, namely the chlorine gas and the oxygen, is improved, but also the safe and stable operation of an industrial device is facilitated.

Owner:FININGS CO LTD

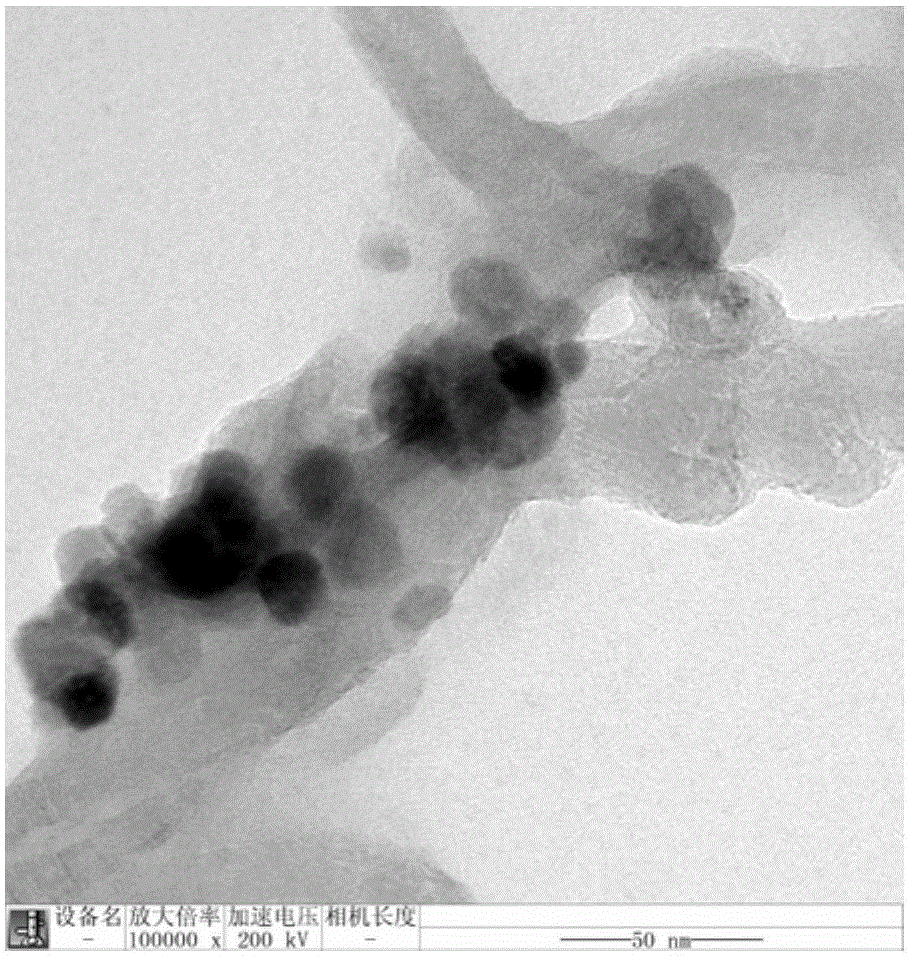

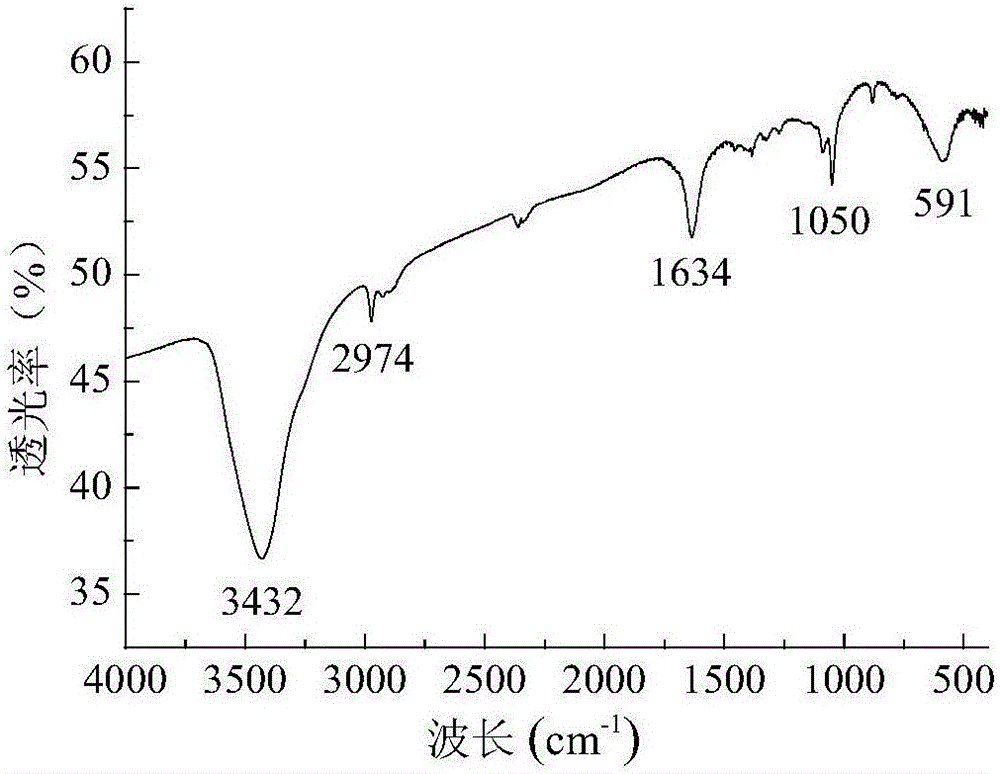

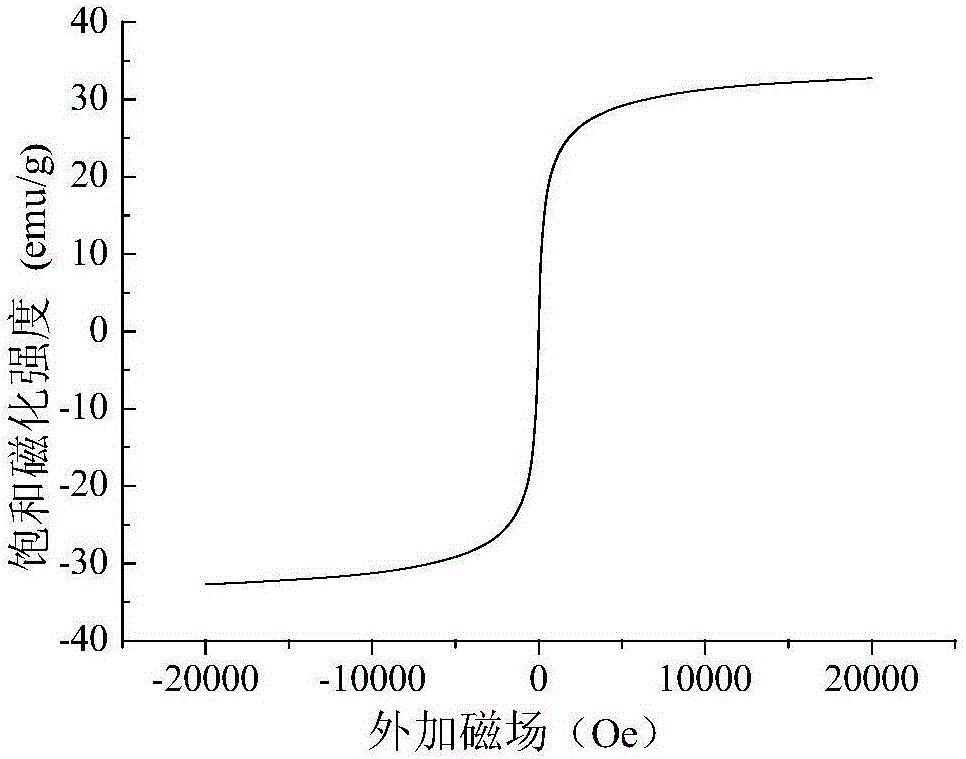

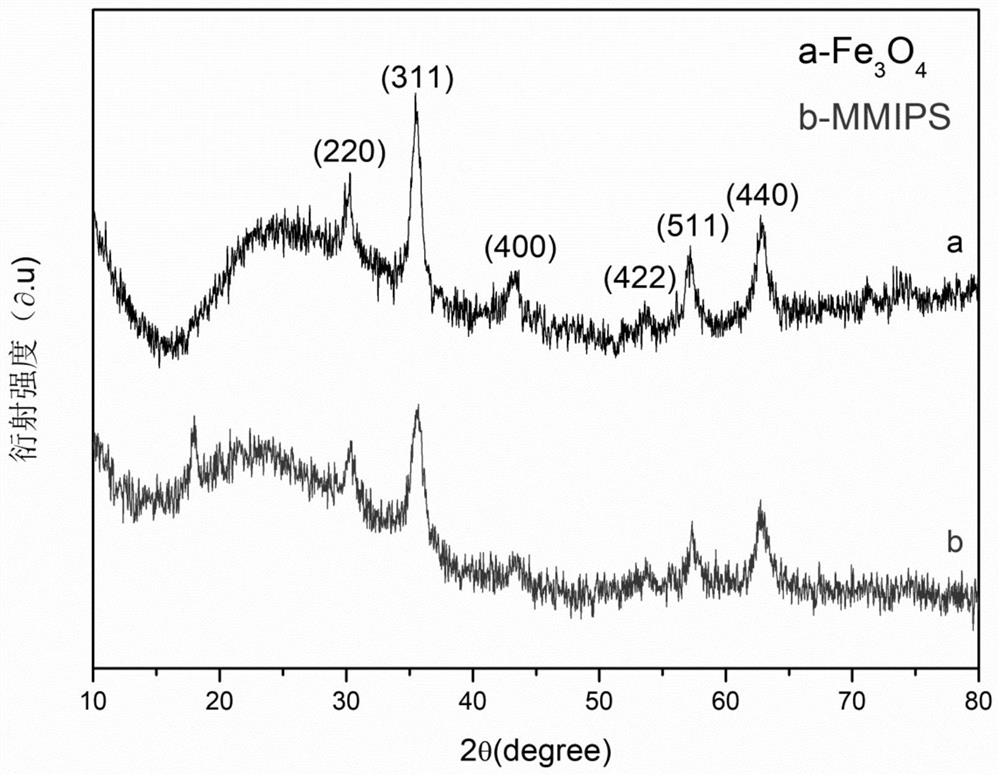

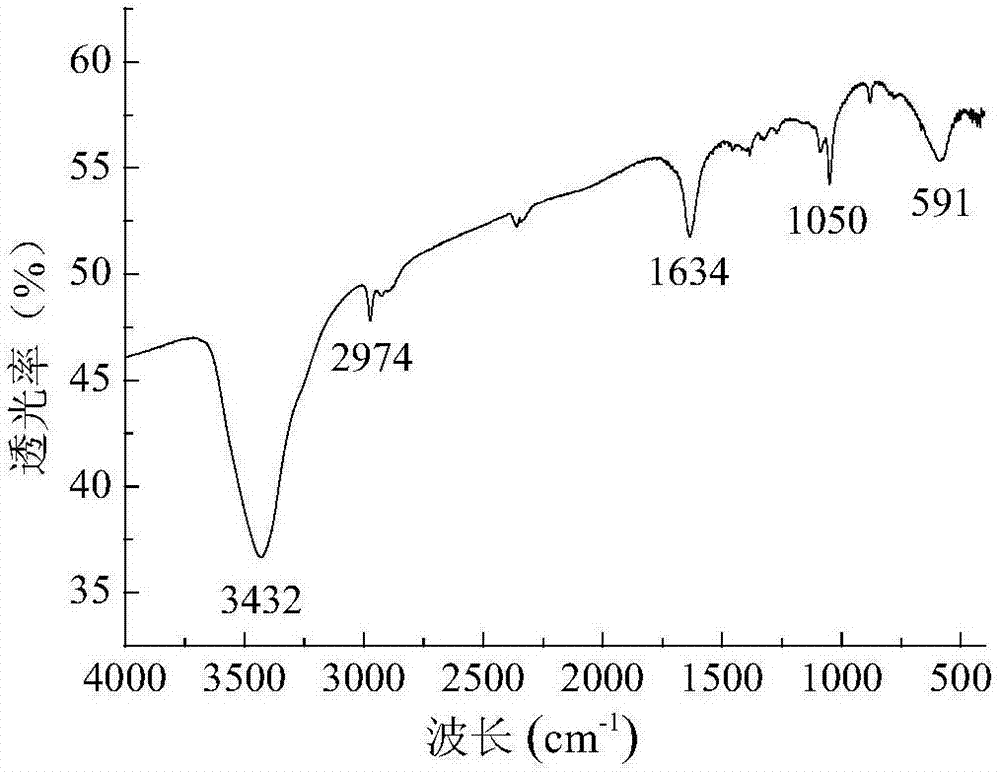

Methods for preparing and using sudan red magnetic molecularly imprinted polymer

InactiveCN103059206AImprove magnetic propertiesFacilitate adsorption and separationOscillatory reactionElution

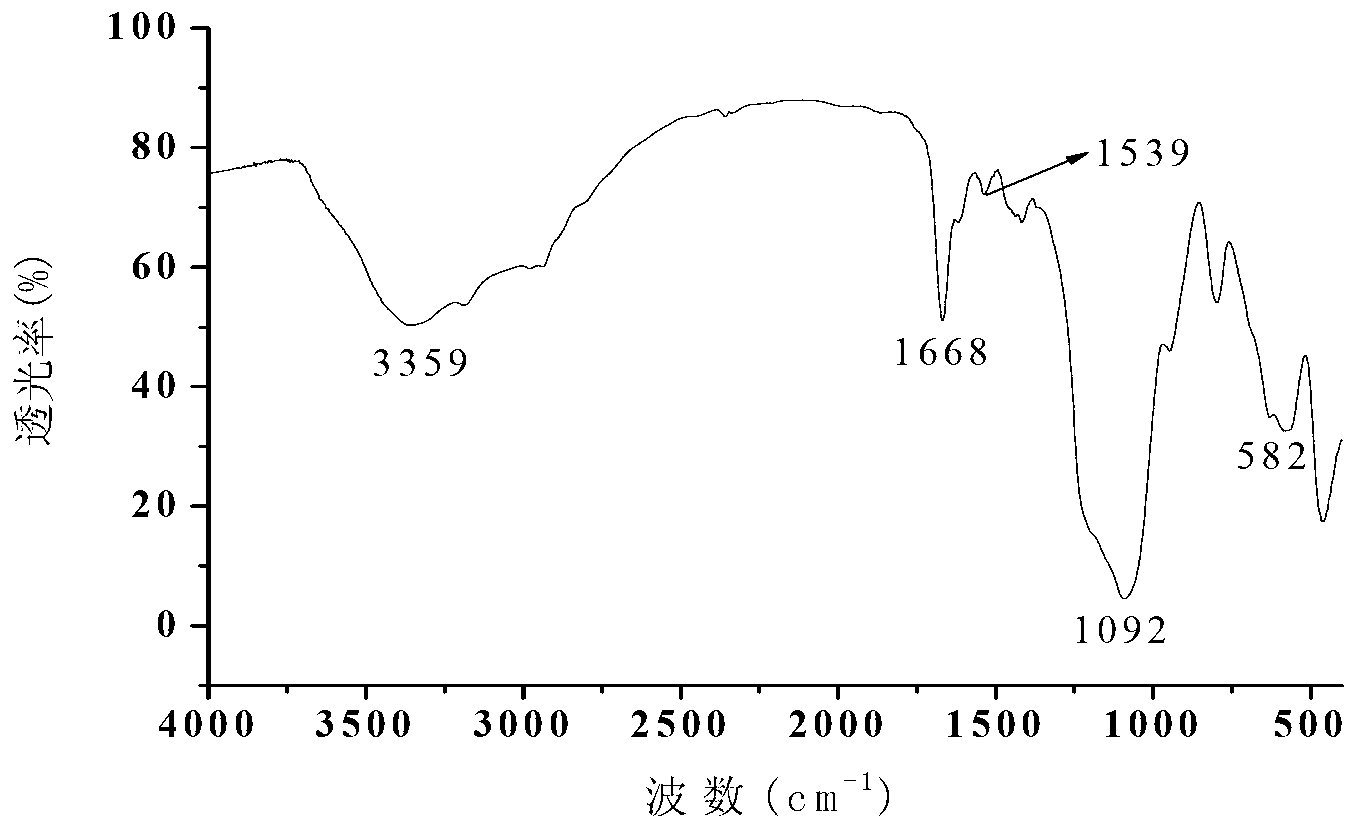

The invention relates to methods for preparing and using a sudan red magnetic molecularly imprinted polymer. The methods aim to solve the problems that the conventional separated / purified sudan red I magnetic molecularly imprinted polymer has a 'solution polymerization' phenomenon in the synthesis process and the obtained separated / purified sudan red I magnetic molecularly imprinted polymer has a non-uniform spatial network structure. The preparation method comprises the following steps of: 1, preparation of Fe3O4; 2, preparation of magnetic SiO2; 3, preparation of aminated magnetic SiO2; 4, preparation of initiator / magnetic SiO2; and 5, polymerization reaction. The using method comprises the following steps of: adding the sudan red magnetic molecularly imprinted polymer into a sample solution containing sudan red, and then sequentially performing oscillatory reaction, magnetic separation and elution. The method is mainly used for preparing the sudan red magnetic molecularly imprinted polymer.

Owner:NORTHEAST FORESTRY UNIVERSITY

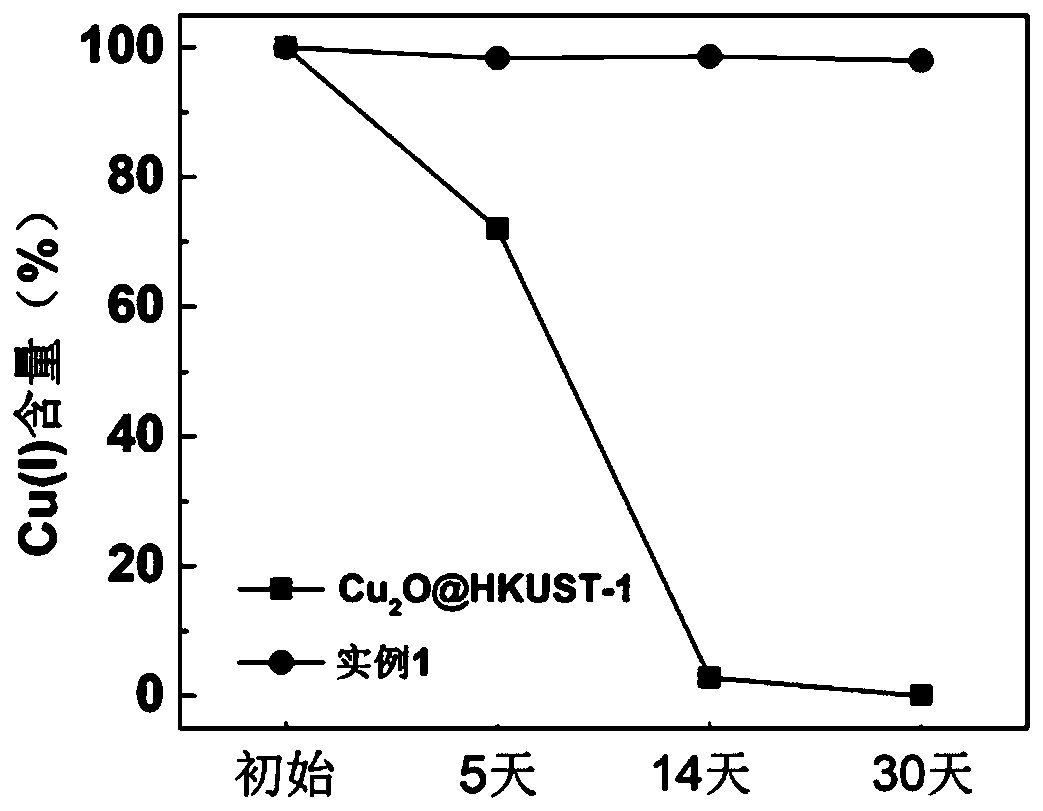

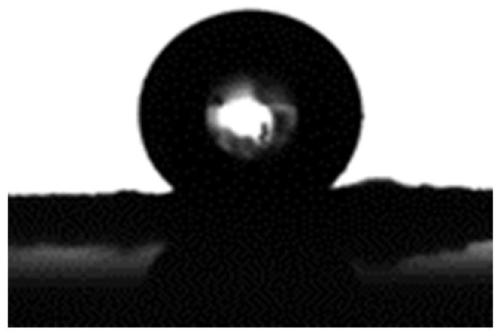

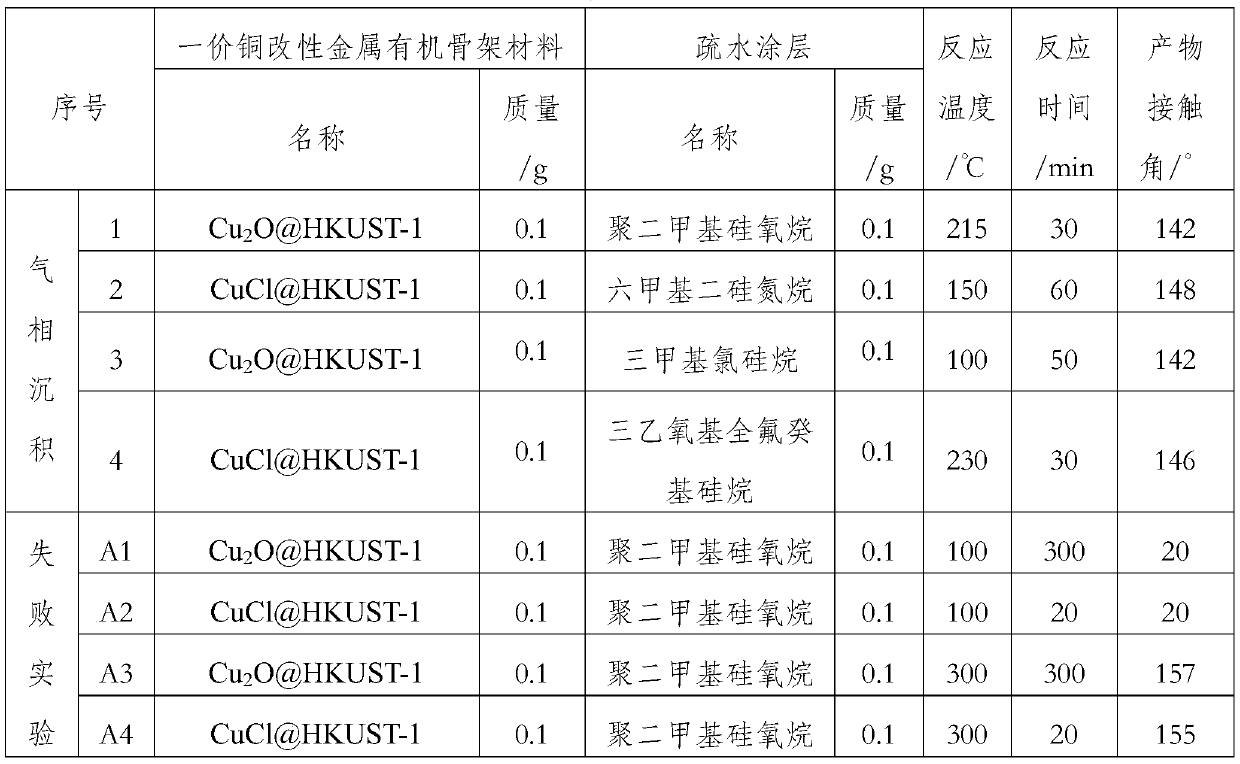

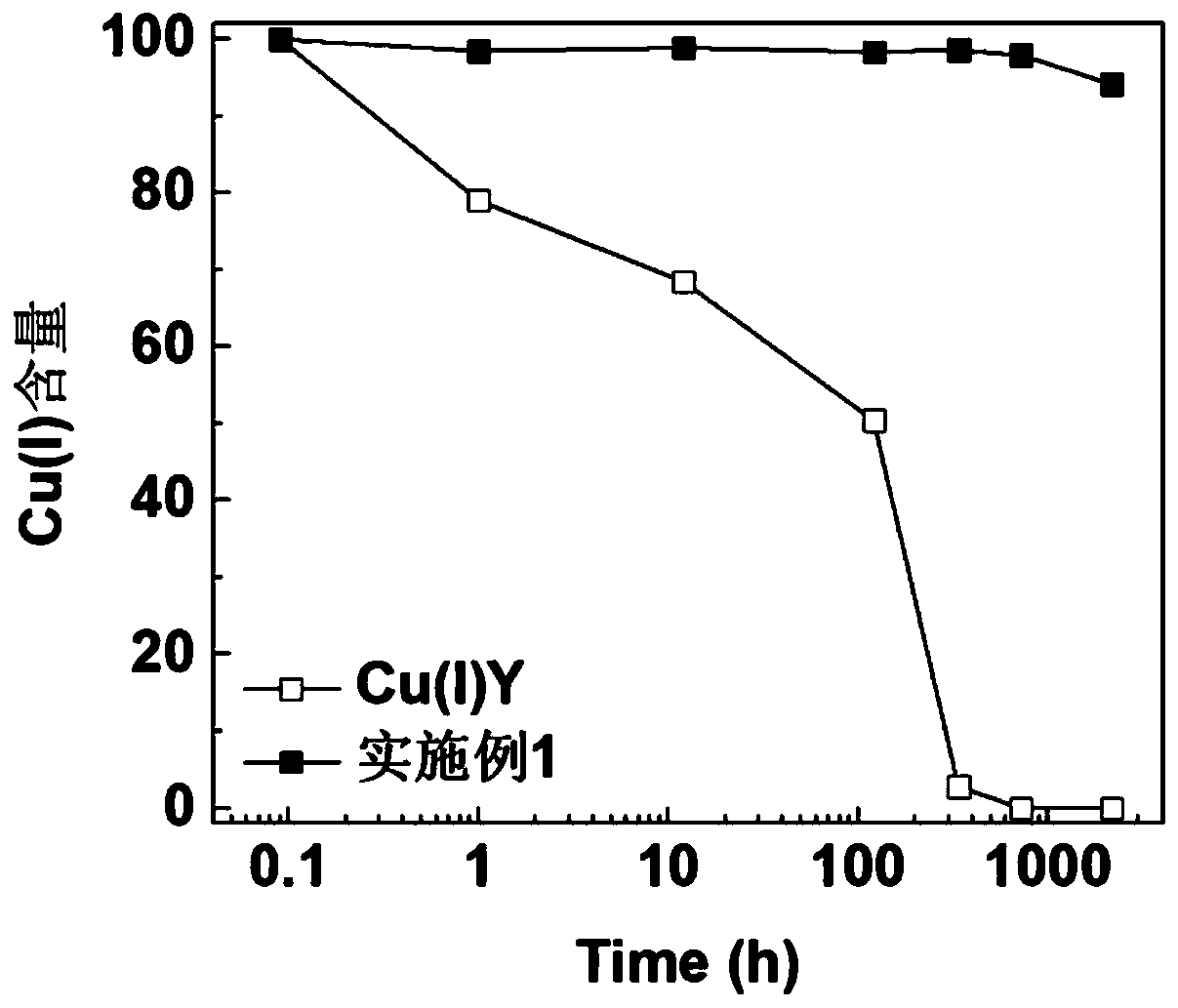

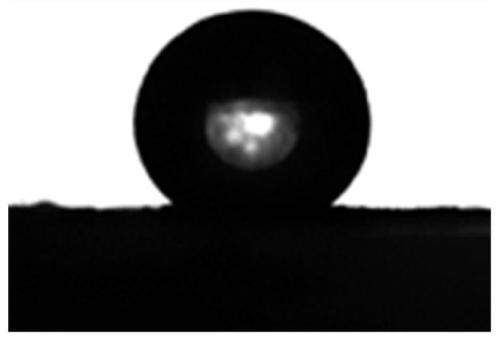

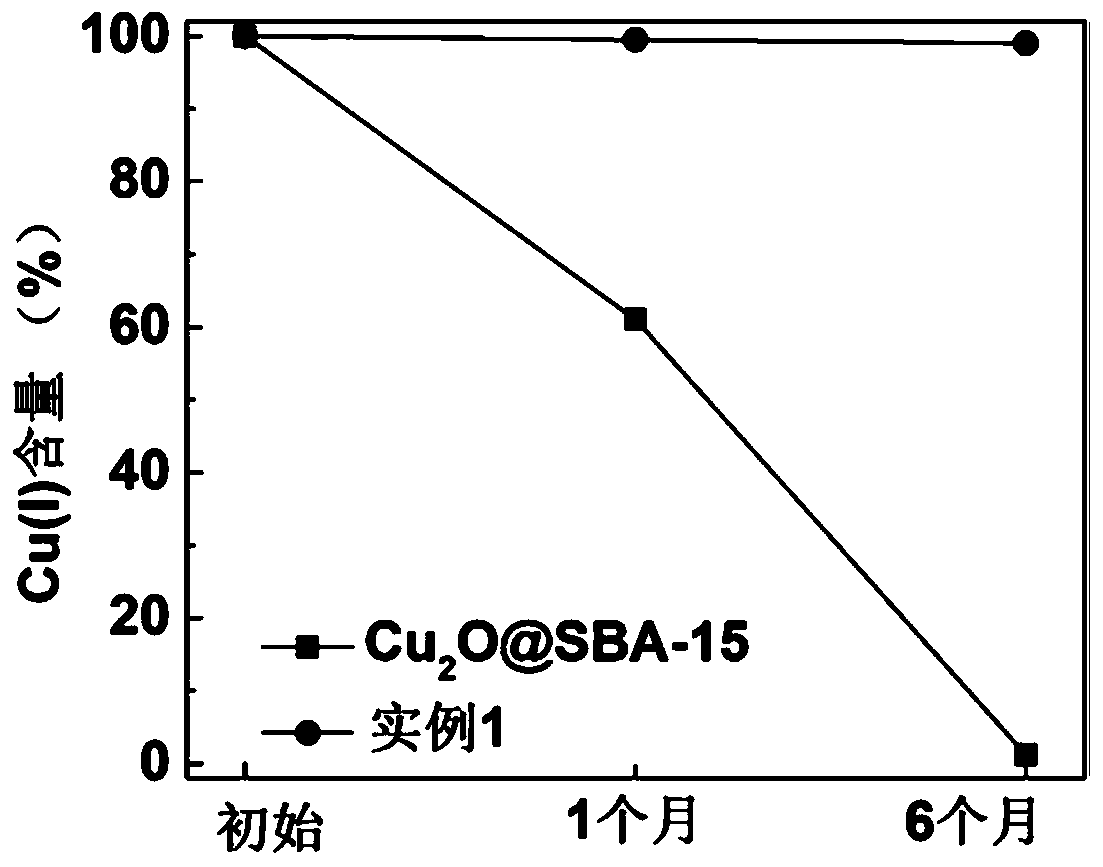

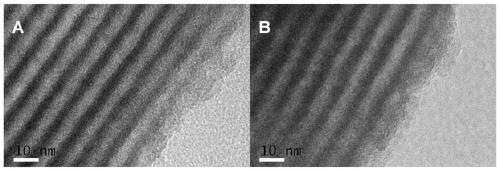

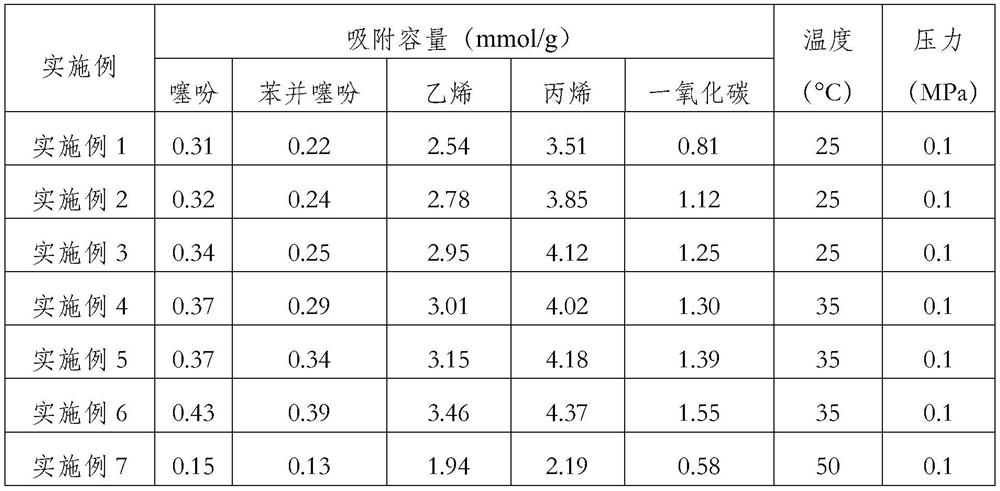

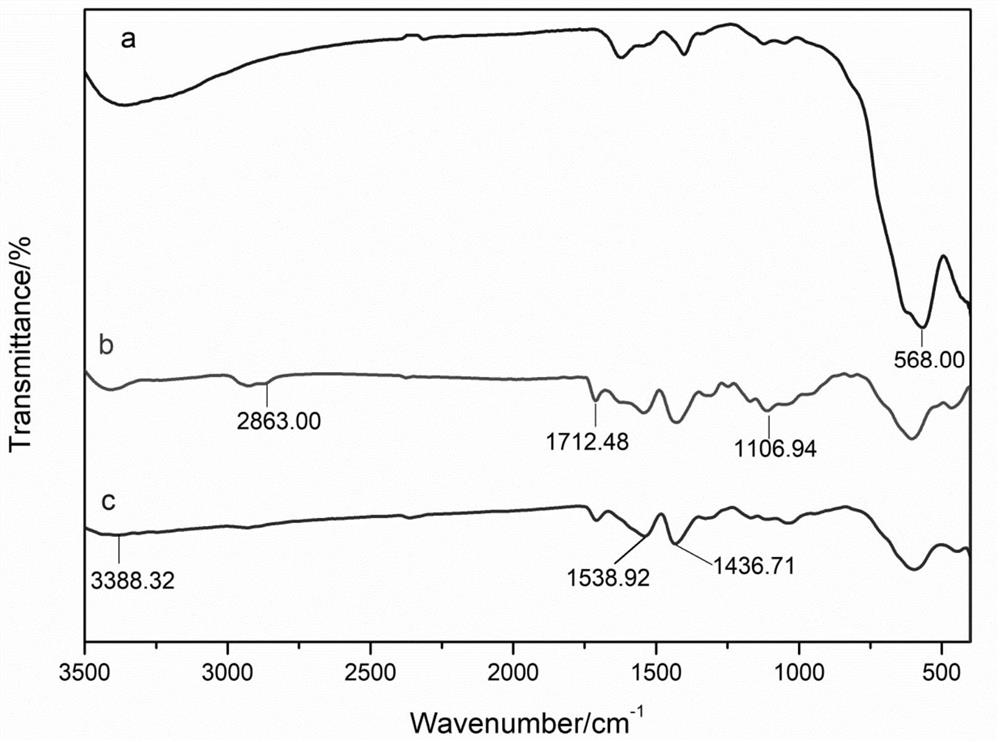

Preparation and application of high-stability cuprous modified metal organic framework material

PendingCN110314653AImprove moisture resistanceImprove stabilityOther chemical processesHydrocarbon oils refiningAlkaneMetal-organic framework

The invention discloses preparation and application of a high-stability cuprous modified metal organic framework material. The high-stability cuprous modified metal organic framework material is involved and comprises a hydrophobic coating and a cuprous modified metal organic framework material; the mass ratio of the hydrophobic coating to the cuprous modified metal organic framework material is (0.02-0.3):1. The preparation method of the high-stability cuprous modified metal organic framework material is further involved. The method comprises the step that the surface of the cuprous modifiedmetal organic framework is coated with the hydrophobic coating. The stability and humidity resistance of the high-stability cuprous modified metal organic framework material are high, and the high-stability cuprous modified metal organic framework material can be applied to desulfuration of fuel oil, separation of olefin and alkane and recycling of carbon monoxide.

Owner:NANJING UNIV OF TECH

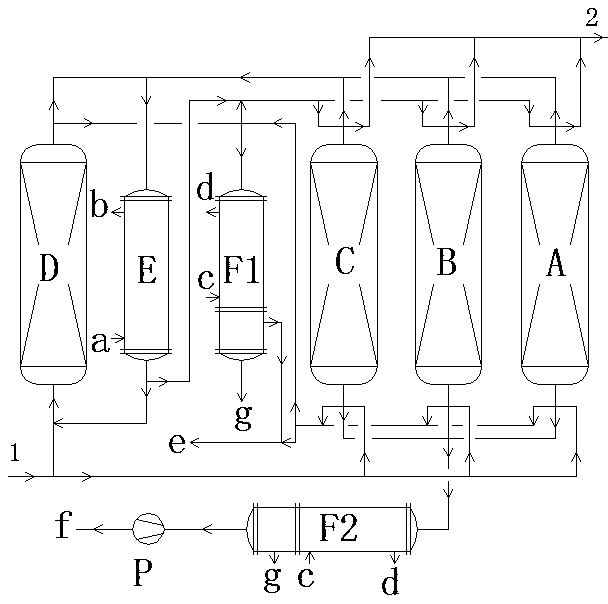

Method of recovering chlorine and oxygen from chlorine-containing oxygen-containing gas mixture

ActiveCN103832975AHigh purityHigh recovery rateOxygen/ozone/oxide/hydroxideChlorine/hydrogen-chloride purificationEngineeringAdsorption separation

The invention discloses a method of recovering chlorine and oxygen from a chlorine-containing oxygen-containing gas mixture. An exhaust mixture, which is obtained by subjecting reaction products of hydrogen chloride oxidation to water adsorption to remove unreacted hydrogen chloride, is adopted as a raw material gas. The exhaust mixture is separated by a.) a step of subjecting the raw material gas to adsorption, separation and drying to remove residual water in the exhaust; and b.) a step of subjecting the dehydrated gas to temperature- & pressure- swing adsorption to achieve separation of the chlorine and the oxygen, wherein the quality of the separated chlorine and the quality of the separated oxygen both meet quality requirements for being directly used as process raw materials. According to the method, an adsorption separation technology is adopted to replace and thoroughly change a traditional drying dehydration technology with concentrated sulfuric acid, and therefore problems of corrosion to equipment materials, difficult treatment of produced dilute sulfuric acid, low dehydration efficiency, pollution to the environment, and the like are solved. The method also develops a technology of separating the chlorine and the oxygen by utilization of temperature- & pressure- swing adsorption (T&PSA), thus increasing the separation efficiency and enhancing adsorption capability of an adsorption tower.

Owner:FININGS CO LTD

Preparation and application of high-stability cuprous modified molecular sieve material

PendingCN110314645AImprove moisture resistanceImprove stabilityGas treatmentOther chemical processesAlkaneMolecular sieve

The invention discloses preparation and application of a high-stability cuprous modified molecular sieve material. The high-stability cuprous modified molecular sieve material is involved and comprises a hydrophobic coating and a cuprous modified molecular sieve; the mass ratio of the hydrophobic coating to the cuprous modified molecular sieve is (0.02-0.3):1. The preparation method of the high-stability cuprous modified molecular sieve material is further involved. The method comprises the step that the surface of the cuprous modified molecular sieve is coated with the hydrophobic coating. The stability and humidity resistance of the high-stability cuprous modified molecular sieve material are high, and the high-stability cuprous modified molecular sieve material can be applied to desulfuration of fuel oil, separation of olefin and alkane and recycling of carbon monoxide.

Owner:NANJING UNIV OF TECH

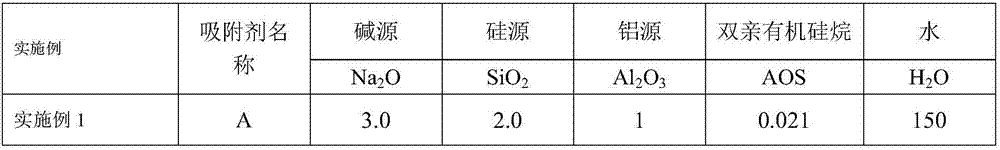

N-alkane adsorption and separation adsorbent and preparation method thereof

PendingCN106943994AAdsorption equilibrium time is shortImprove adsorption and separation efficiencyOther chemical processesAluminosilicate zeolite type-AAlkaneMolecular sieve

The invention discloses an n-alkane adsorption and separation adsorbent and a preparation method thereof. The preparation method comprises the following steps: adding amphiphilic organosilane used as a soft template into a silicon source and aluminum source mixed sol system, and hydrothermally synthesizing a hierarchical porous 4A molecular sieve with a microporous-mesoporous structure; and removing the soft template from the 4A molecular sieve, rolling the soft template removed 4A molecular sieve and a binder to form small spheres with the particle size of 0.2-0.8 mm, drying and calcining the small spheres, carrying out calcium ion exchange and activation to obtain the 5A molecular sieve adsorbent with a microporous-mesoporous structure. The adsorbent comprises 90-97 wt% of 5A molecular sieve and 3-10 wt% of the binder. The hierarchical porous 5A molecular sieve synthesized in the invention keeps high equilibrium adsorption quantity to n-alkanes, and substantially improves the diffusion coefficient of the n-alkanes in the molecular sieve, so the adsorption and separation rate is improved.

Owner:CHINA CATALYST HLDG CO LTD

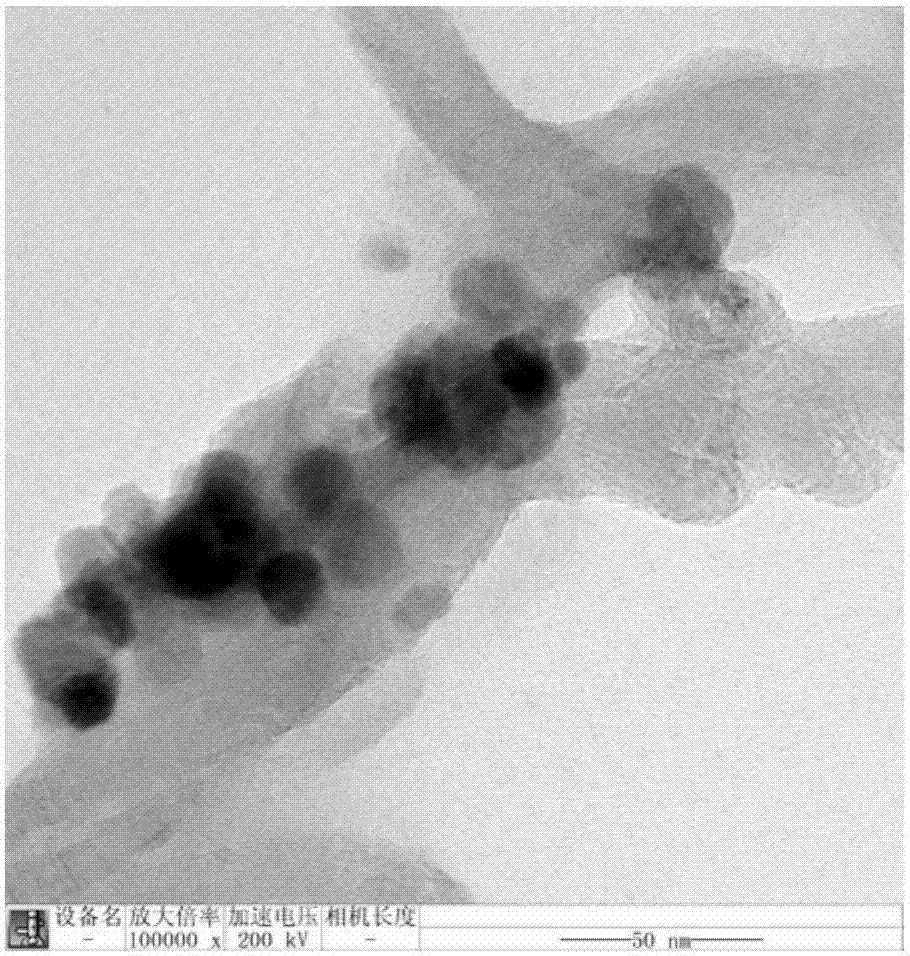

Preparation and application methods of carbon-nanotube-base magnetic bactericide molecularly-imprinted polymer

ActiveCN105693961AFast adsorptionRaw materials are easy to getIon-exchange process apparatusOther chemical processesProblem of timeFiltration

The invention provides preparation and application methods of a carbon-nanotube-base magnetic bactericide molecularly-imprinted polymer, relating to preparation and application methods of bactericide molecularly-imprinted polymers. The invention aims to solve the problems of time consuming, high organic solvent consumption and low selectivity in the sample pretreatment technique in the existing bactericide residue analysis, the problem of the solution polymerization phenomenon in the existing bactericide molecularly-imprinted polymer synthesis process, and the problem that the solution separation process needs the vacuum filtration or centrifuging step. The preparation method comprises the following steps: 1. activating carbon nanotubes; 2. hydroxylating the carbon nanotubes; 3. preparing the magnetic carbon nanotubes; 4. preparing the initiator / magnetic carbon nanotubes; and 5. carrying out polymerization reaction. The application method comprises the following steps: adding the carbon-nanotube-base magnetic bactericide molecularly-imprinted polymer into a bactericide-containing sample solution, and sequentially carrying out oscillation, magnetic resolution and elution.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparing method of modified aluminum oxide dehydrant

ActiveCN103706324AHigh strengthLarge hole volumeOther chemical processesDispersed particle separationCatalytic oxidationSilica gel

The invention discloses a preparing method of a modified aluminum oxide dehydrant. The preparing method comprises the following steps: uniformly blending alumina gel, silica gel, calcium oxide, zinc oxide and sesbania and carrying out kneading, molding, granulating, primary drying, primary roasting, impregnating, secondary drying and secondary roasting in sequence to prepare finished products, carrying out dehydration process before chlorine and oxygen are separated from the mixed gas generated by catalytic oxidation reaction of hydrogen chloride by using adsorption separation method, the mass ratios of alumina gel to silica gel to calcium oxide to zinc oxide to sesbania are (70-82):(7-14):(0.5-2.0):(5-10):(5-10). In the preparing method, water absorption drying agent which is allowed to be used in chlorine-containing gas with small amount of water, and can form the compound absorption bed layer together with the silica gel, the compound bed absorption agent is arranged at the gas outlet end of the compound absorption bed layer to deeply dry and dehydrate gas.

Owner:FININGS CO LTD

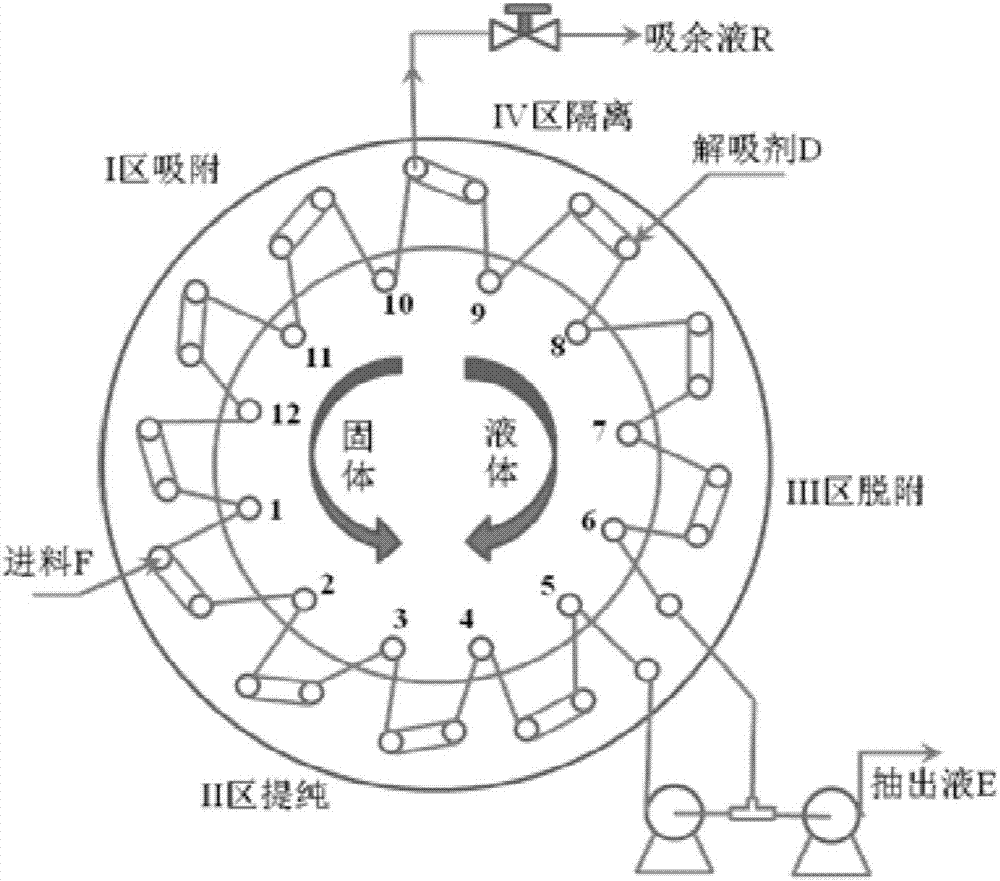

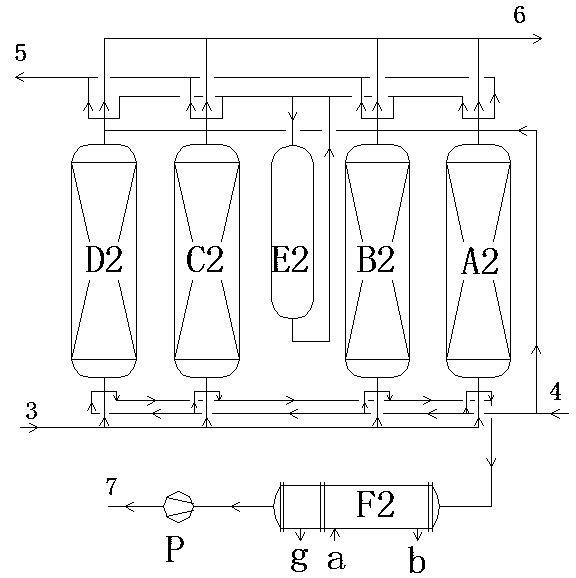

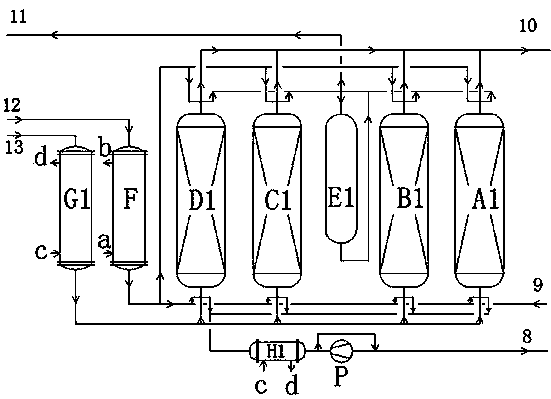

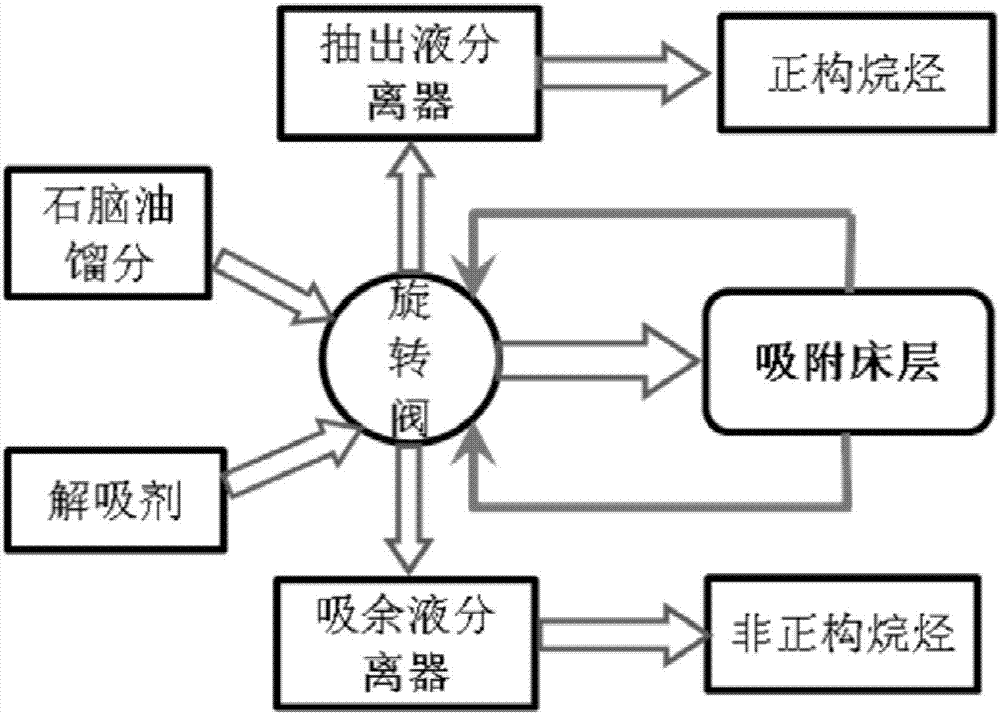

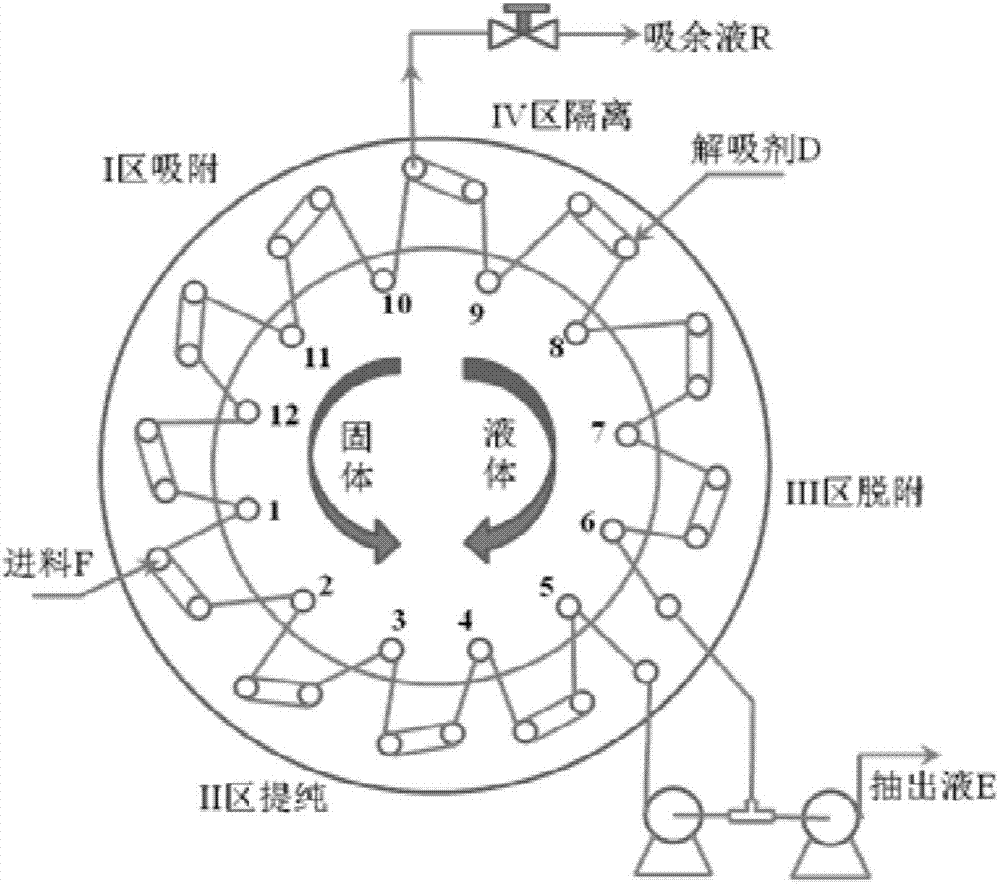

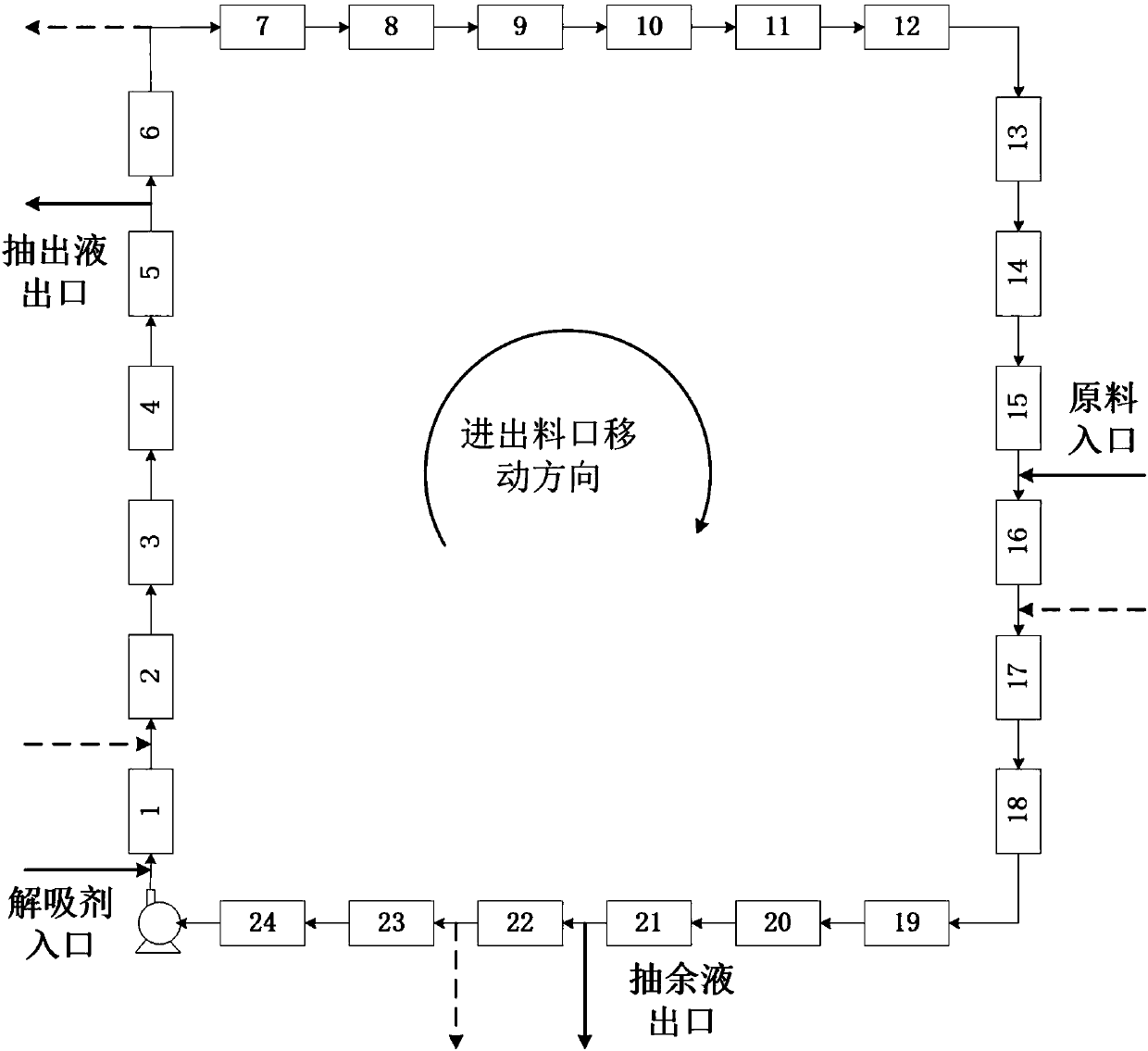

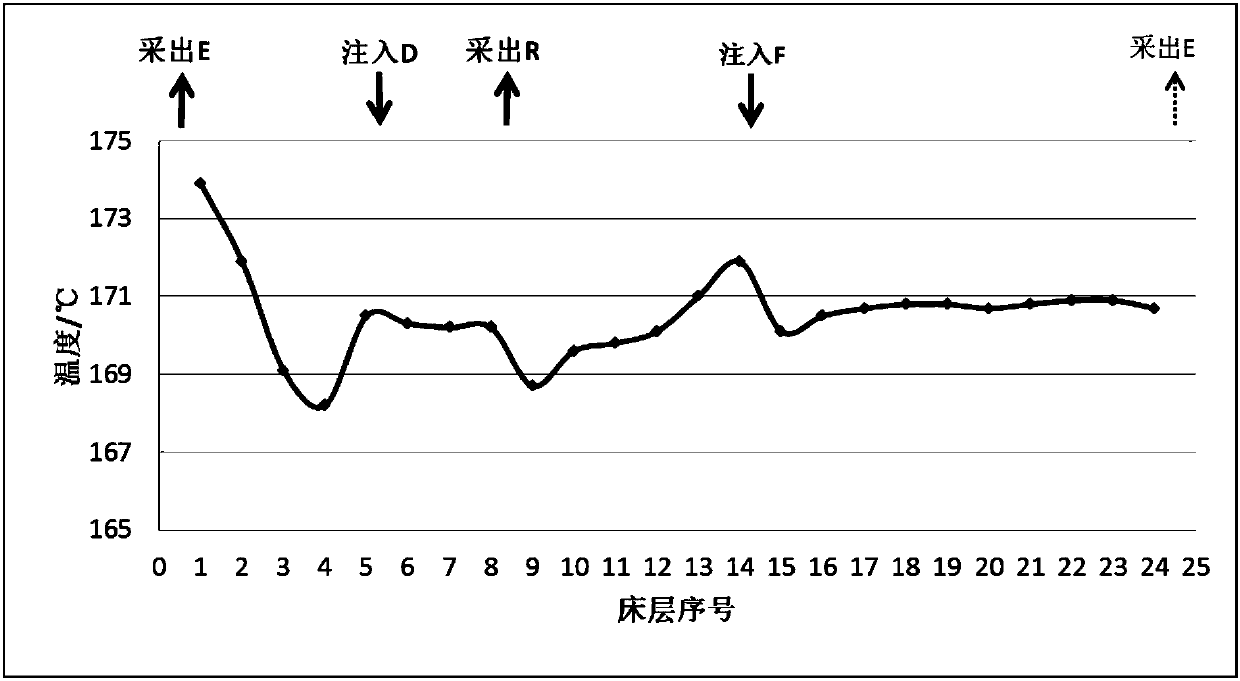

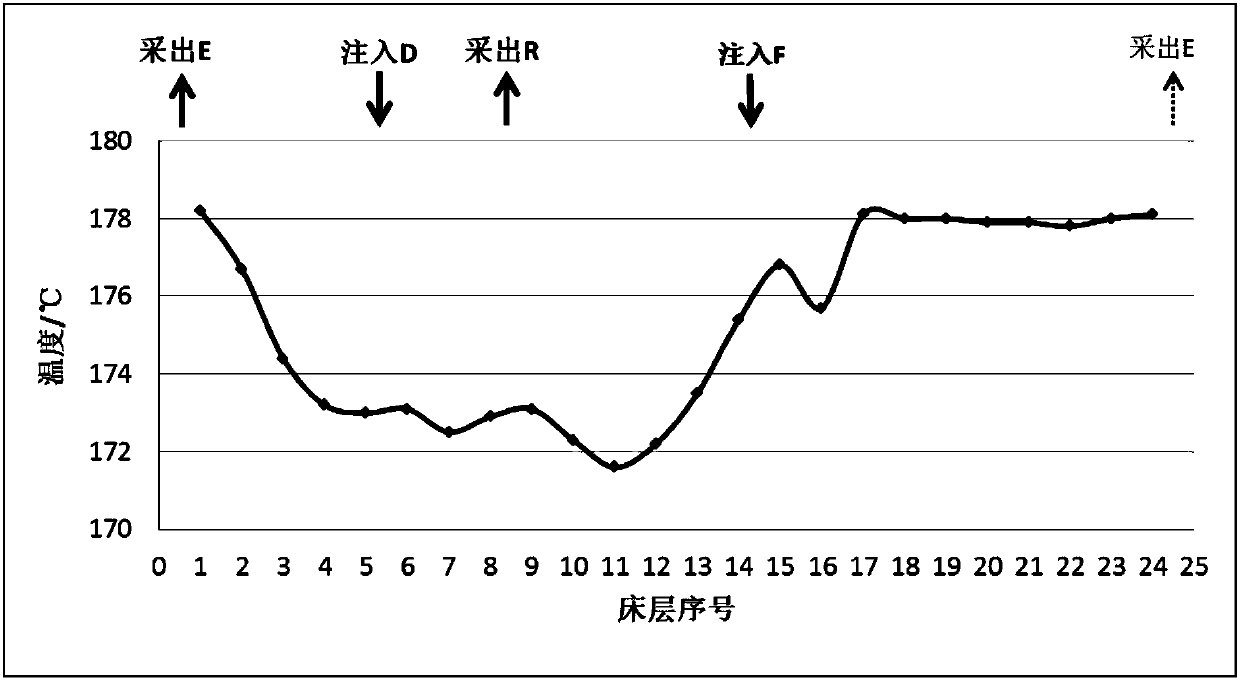

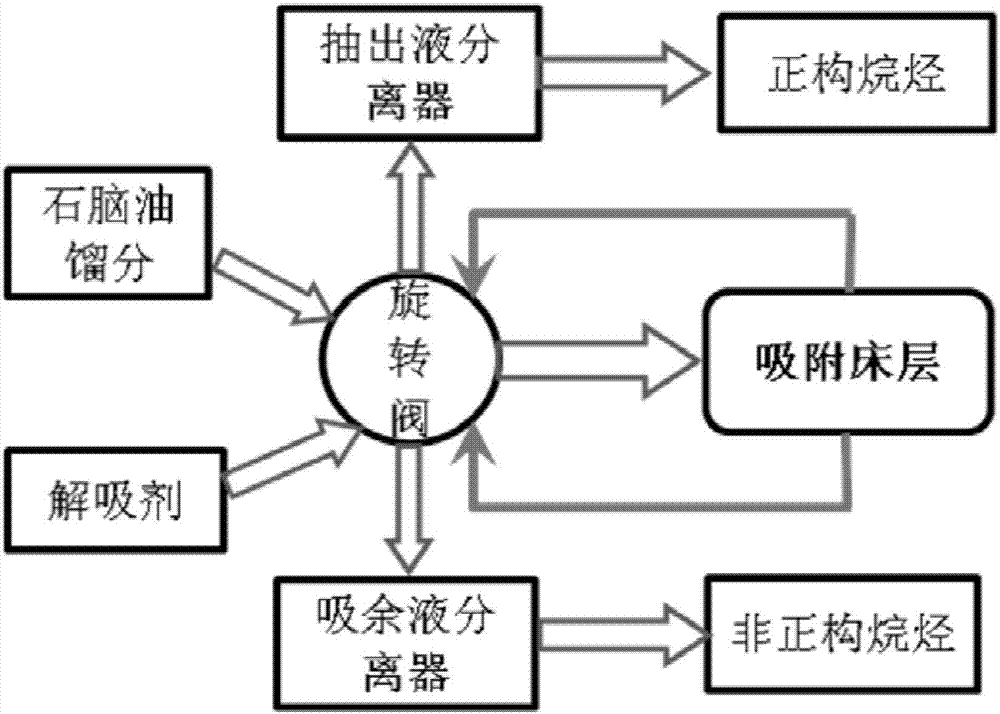

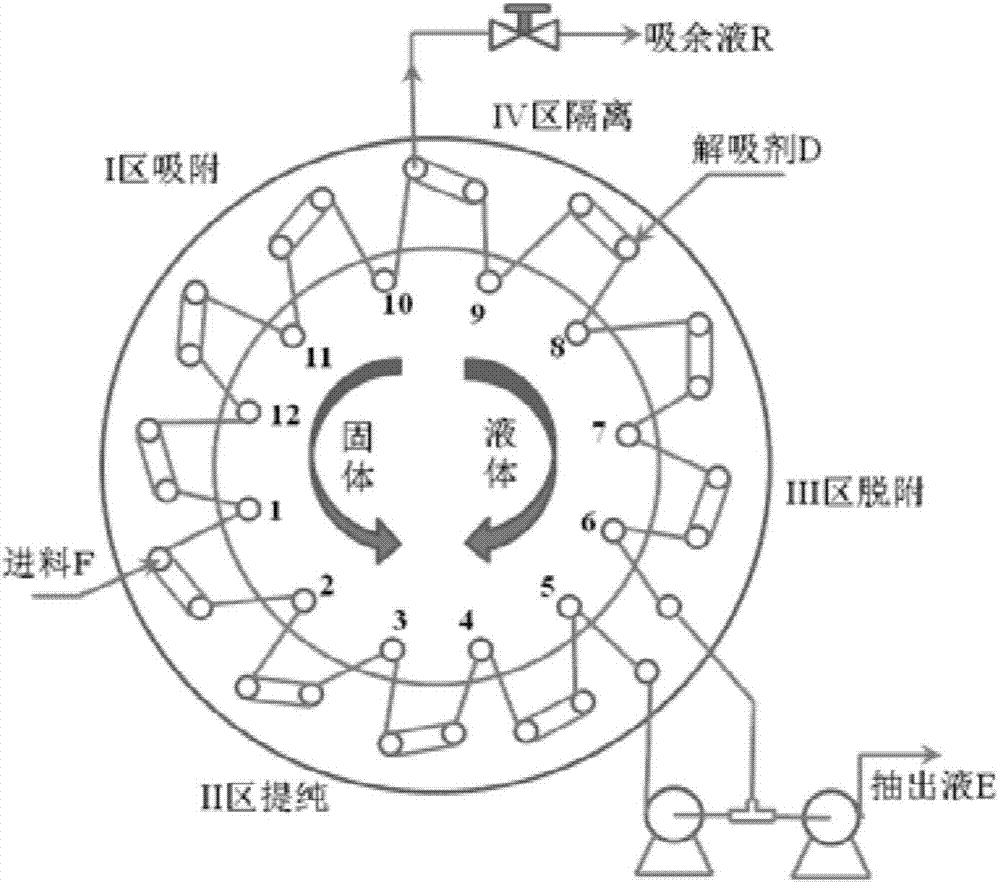

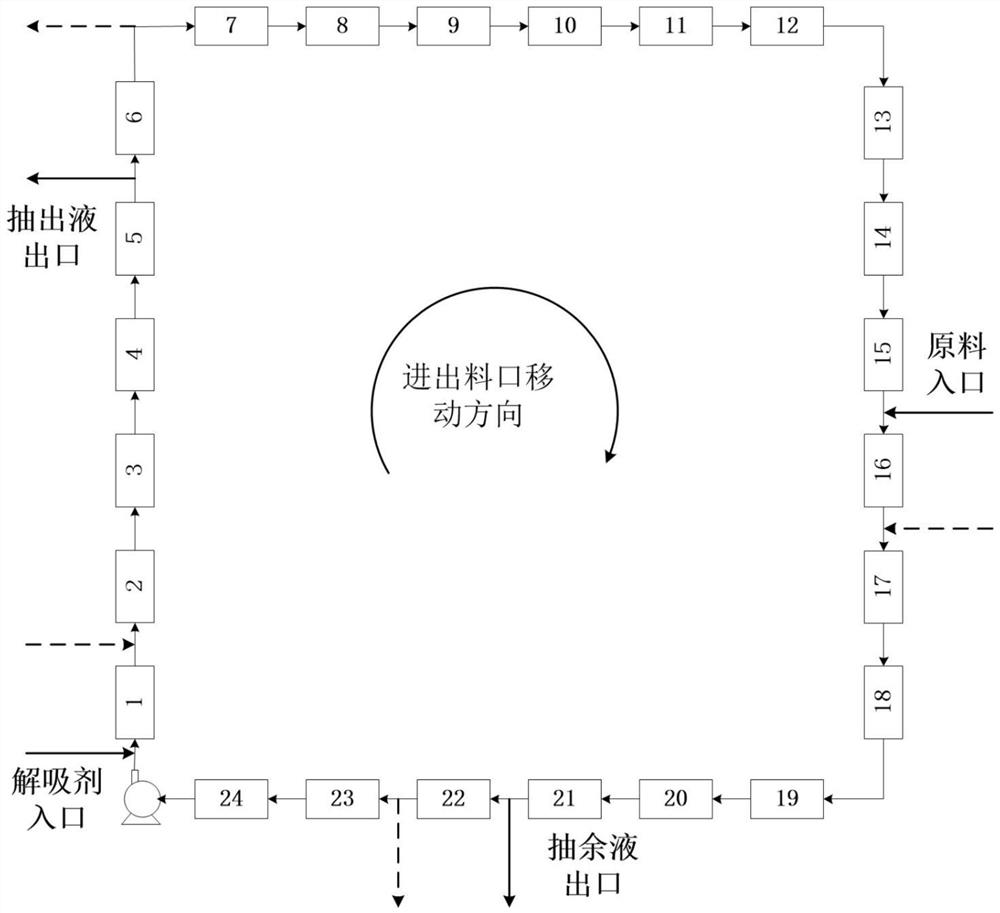

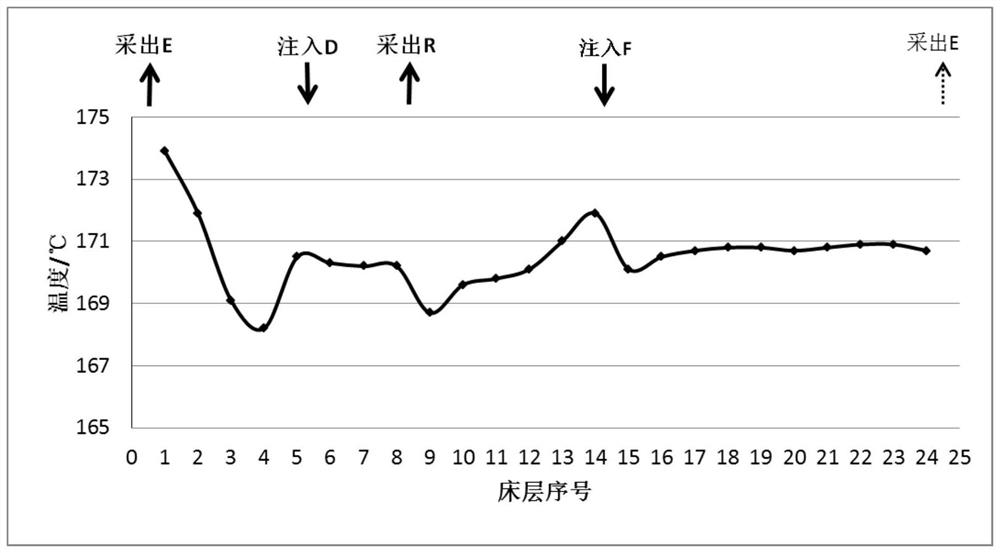

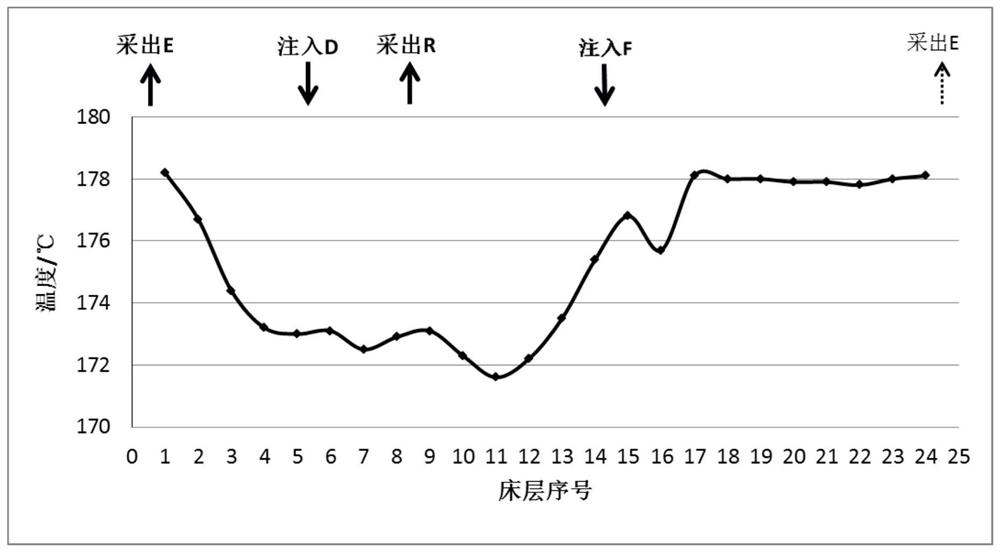

Method for simulated moving bed adsorption separation of p-xylene in C8 aromatic hydrocarbon

ActiveCN108017502AImprove adsorption and separation efficiencyAdsorption purification/separationChemistrySimulated moving bed

The invention discloses a method for liquid phase simulated moving bed adsorption separation of p-xylene in C8 aromatic hydrocarbon. The method includes: introducing a C8 aromatic hydrocarbon raw material into a simulated moving bed to adsorb bed p-xylene therein to obtain raffinate, introducing a desorption agent into adsorption bed layers to desorb the adsorbed p-xylene, discharging the obtainedextracted liquid out of the simulated moving bed, separating the adsorption bed layers into a desorption area, a purification area, an adsorption area and an isolation area by the materials going inand out of the simulated moving bed, wherein the adsorbent active ingredient is BaX or BaKX zeolite, and the desorption agent is p-diethylbenzene, controlling the temperature of the C8 aromatic hydrocarbon raw material entering the adsorption bed layers of the simulated moving bed at 100-155DEG C, and the temperature of the desorption agent introduced into the adsorption bed layers of the simulated moving bed at 170-210DEG C. The method can improve the separation efficiency of the process for simulated moving bed separation of p-xylene in C8 aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

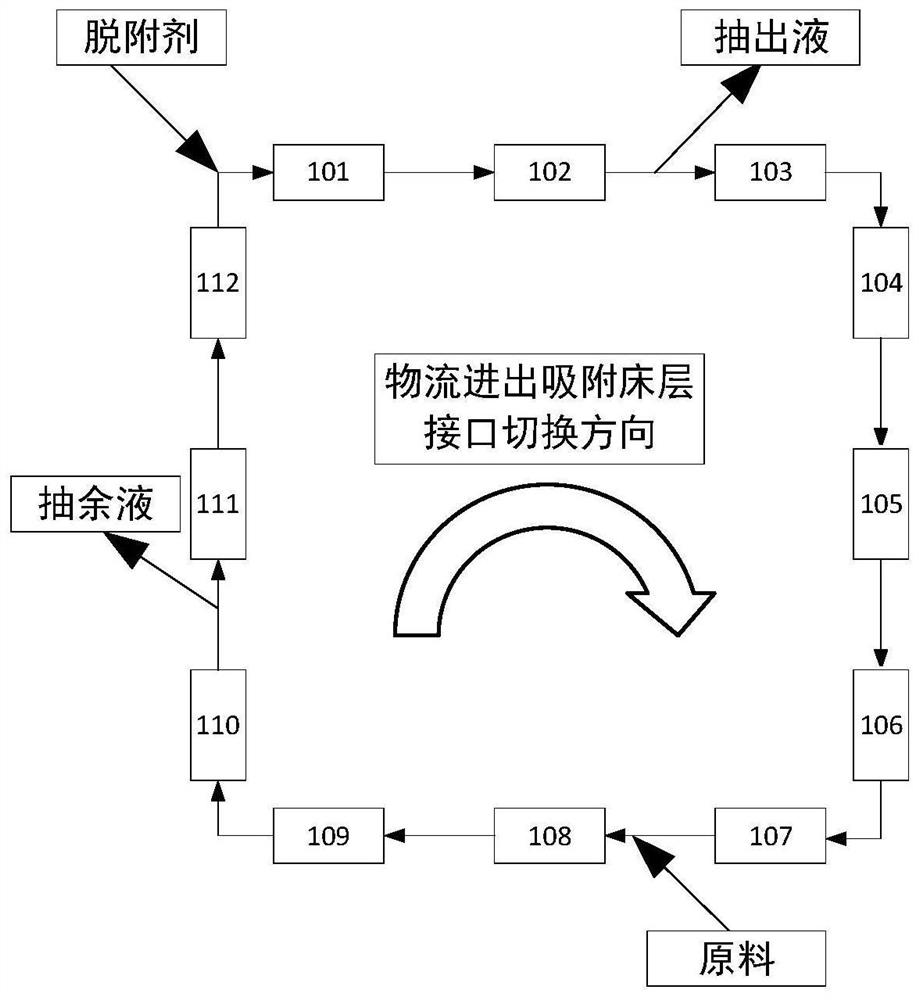

Method for adsorbing and separating p-cresol and m-cresol

ActiveCN111689838AHigh purityImprove adsorption and separation efficiencyOrganic chemistryOrganic compound preparationMolecular sieveFluid phase

The invention discloses a method for adsorbing and separating p-cresol and m-cresol. The method comprises the following steps: feeding a mixture of p-cresol and m-cresol into an adsorption zone of a liquid-phase simulated moving bed to be in contact with an adsorbent, wherein the p-cresol is adsorbed by the adsorbent while the m-cresol is not adsorbed; extracting the liquid as raffinate, introducing a desorption agent into the adsorbent for desorbing the adsorption components and obtaining an extract liquid; wherein the liquid-phase simulated moving bed comprises the following four functionalareas: a first functional area, a second functional area and a third functional area, a desorption zone, a purification zone, an adsorption zone and a buffer zone, the temperature of feeding an adsorption raw material into the adsorption area is 100-230 DEG C; the temperature of feeding a desorption agent into the desorption area is 120-250 DEG C; the temperature of the desorption agent introducedinto the desorption area is controlled to be 10-100 DEG C higher than the temperature of the adsorption raw material introduced into the adsorption area; the active component of the adsorbent is selected from any one of BaX, BaKX and KY molecular sieves, and the desorption agent is a mixture of 30-96% by mass of C3-C5 fatty alcohol and 4-70% by mass of C7-C9 alkane. The method is used for adsorbing and separating a mixture of p-cresol and m-cresol, and high-purity p-cresol and m-cresol products can be respectively obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation and application of high-stability cuprous modified mesoporous oxide material

PendingCN110314643AImprove stabilityImprove moisture resistanceOther chemical processesHydrocarbon oils refiningAlkaneMesoporous material

The invention discloses preparation and application of high-stability cuprous modified mesoporous oxide material. The high-stability cuprous modified mesoporous oxide material is involved and comprises a hydrophobic coating and a cuprous modified mesoporous oxide; the mass ratio of the hydrophobic coating to the cuprous modified mesoporous oxide is (0.02-0.5):1. The preparation method of the high-stability cuprous modified mesoporous oxide material is further involved. The method comprises the step that the surface of the cuprous modified mesoporous oxide is coated with the hydrophobic coating. The stability and humidity resistance of the high-stability cuprous modified mesoporous oxide material are high, and the high-stability cuprous modified mesoporous oxide material can be applied to desulfuration of fuel oil, separation of olefin and alkane and recycling of carbon monoxide.

Owner:NANJING UNIV OF TECH

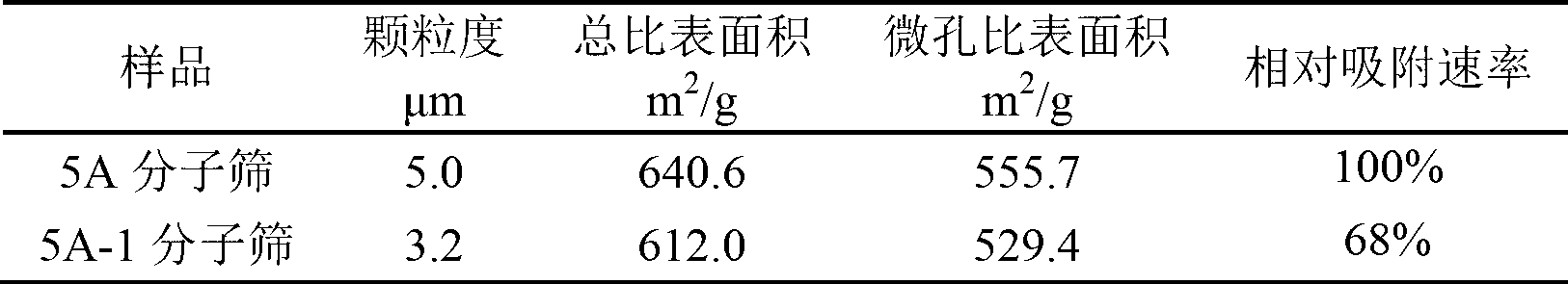

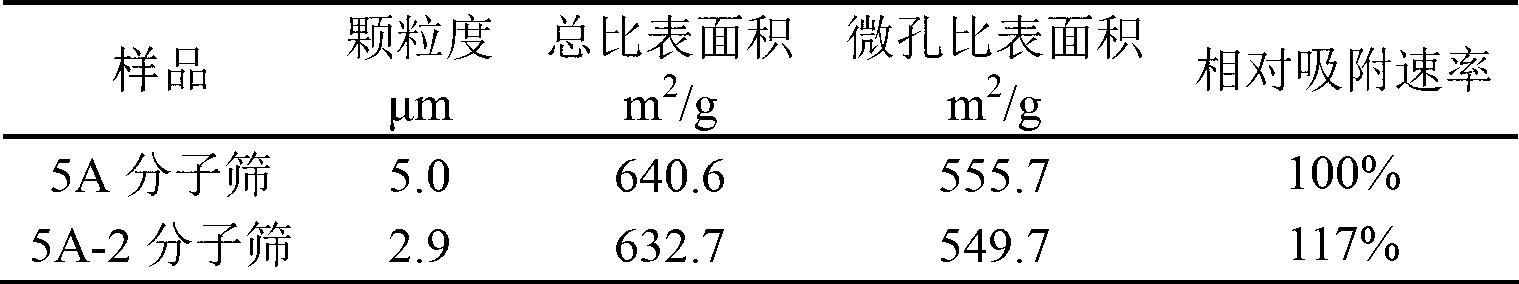

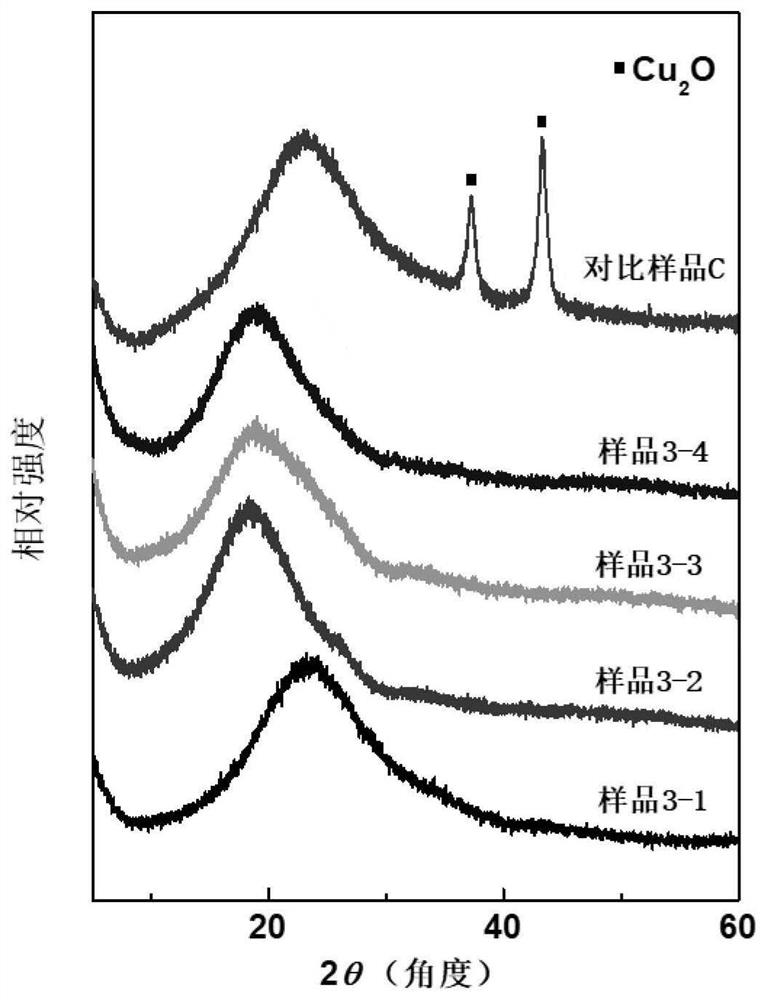

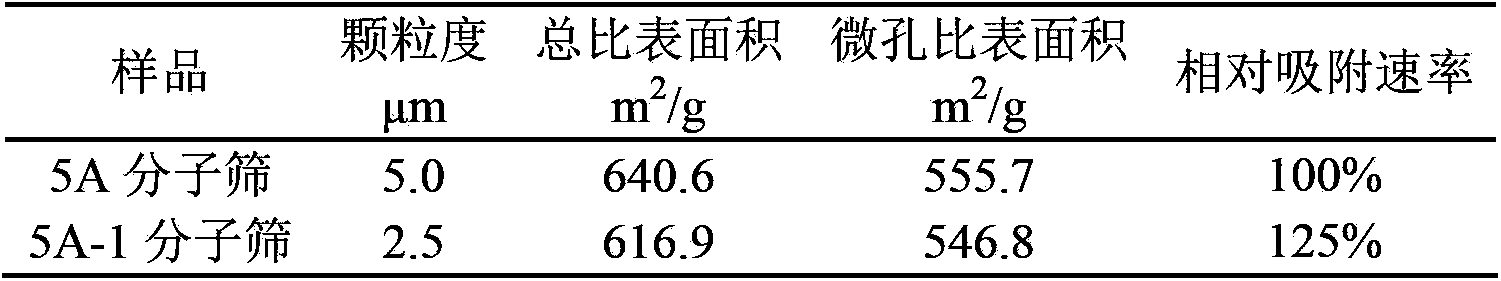

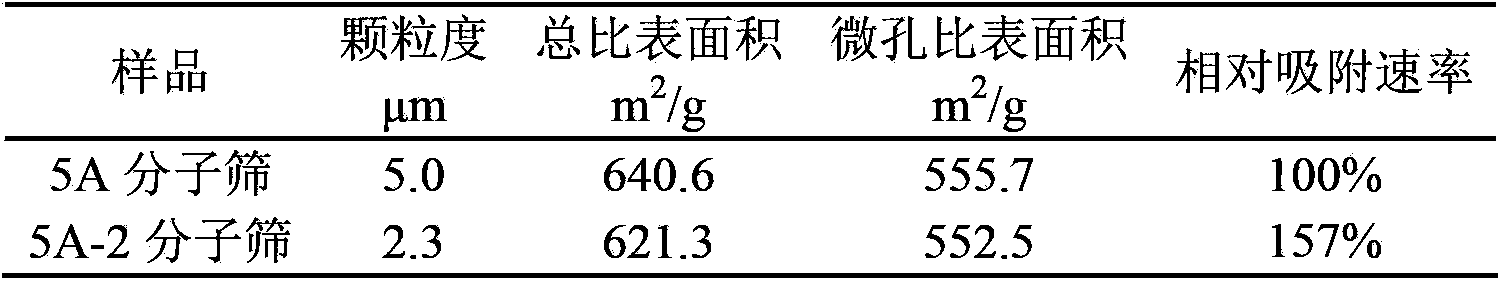

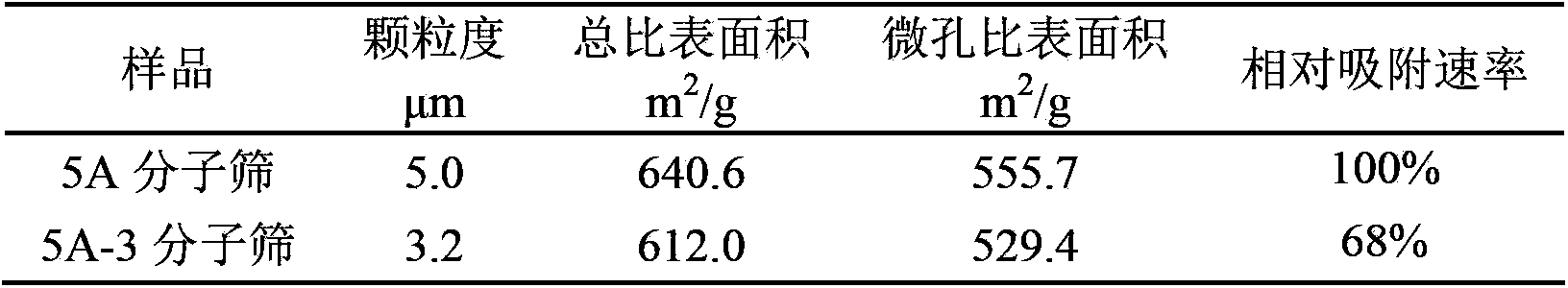

Method for reducing granularity of 5A molecular sieve (MS)

InactiveCN103007877ASmall granularityGuaranteed microporous structureOther chemical processesDispersed particle separationMolecular sieveGranularity

The invention relates to a method for reducing granularity of a 5A molecular sieve (MS). The method comprises the following steps of: dispersing the 5A MS in a dispersing agent to prepare an MS suspension; selecting a grinding medium; setting grinder parameters; and adding the MS suspension and the grinding medium to a grinder to be ground. The method has the advantages that under the condition of keeping the adsorption quantity of the 5A MS changeless, the granularity of the MS is reduced, the adsorption cycle of the 5A MS for producing nitrogen through pressure swing adsorption (PSA) is shortened, the yield of high purity nitrogen is obviously increased, and the economic benefits of nitrogen production through PSA of the MS are increased.

Owner:天津众智科技有限公司

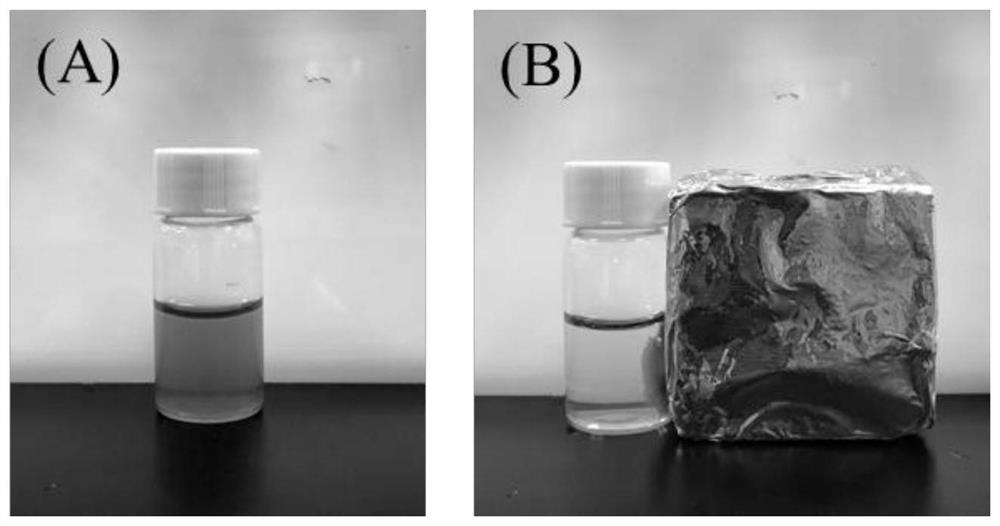

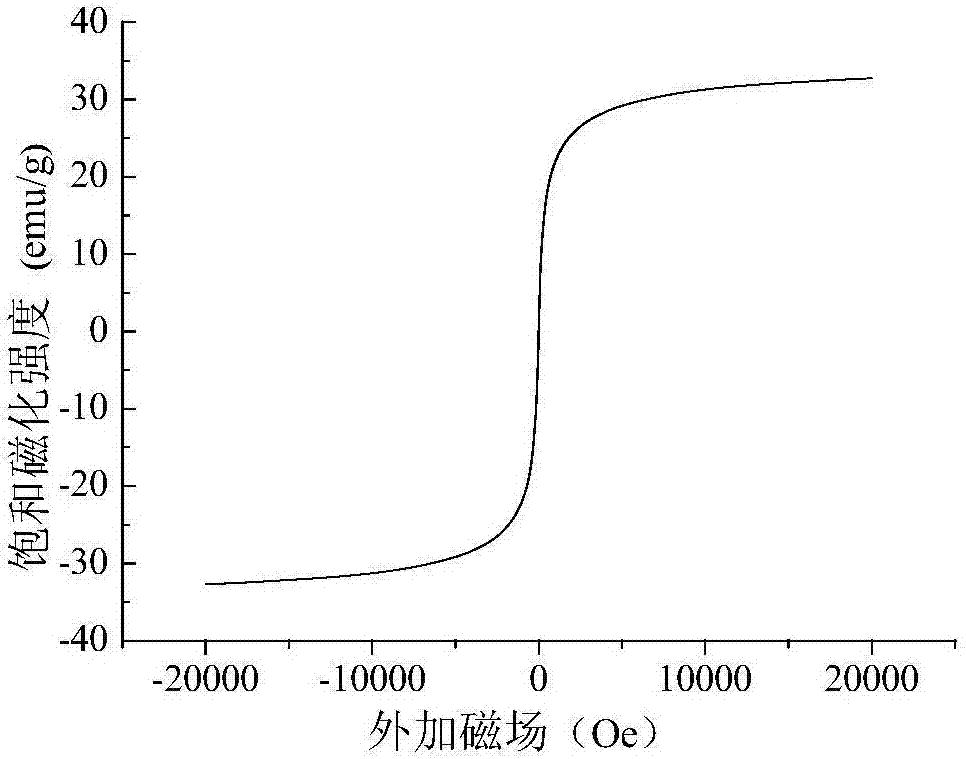

Magnetic Prussian blue-like materials and their preparation and application of adsorbing cesium ions

ActiveCN110327899BEasy to prepareMild reaction conditionsOther chemical processesAlkali metal oxides/hydroxidesMagnetite NanoparticlesDouble bond

The invention relates to a magnetic Prussian blue material and its preparation and application of cesium ions. The preparation method comprises the following steps: under the action of a thermal initiator, Fe 3 o 4 Nanoparticles react with pyridine compounds containing carbon-carbon double bonds, unsaturated aromatic hydrocarbons and oil-soluble cross-linking agents in water, and after the reaction is complete, polymer-wrapped magnetic nanoparticles are obtained; the magnetic nanoparticles are mixed with pentacyanide The monoammine ferrite undergoes a ligand exchange reaction to obtain the magnetic Prussian blue-like material. The magnetic Prussian blue-like material of the present invention can be used to adsorb cesium ions in soil, especially clay, and combined with the pretreatment of cationized chitosan on clay, the adsorption efficiency of cesium ions is high, and efficient purification of soil can be realized.

Owner:SUZHOU UNIV

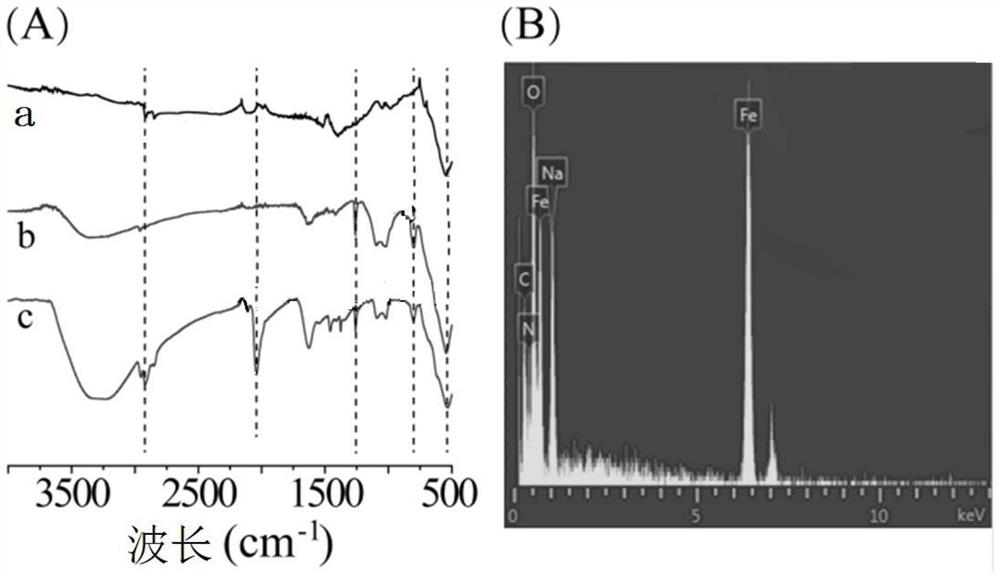

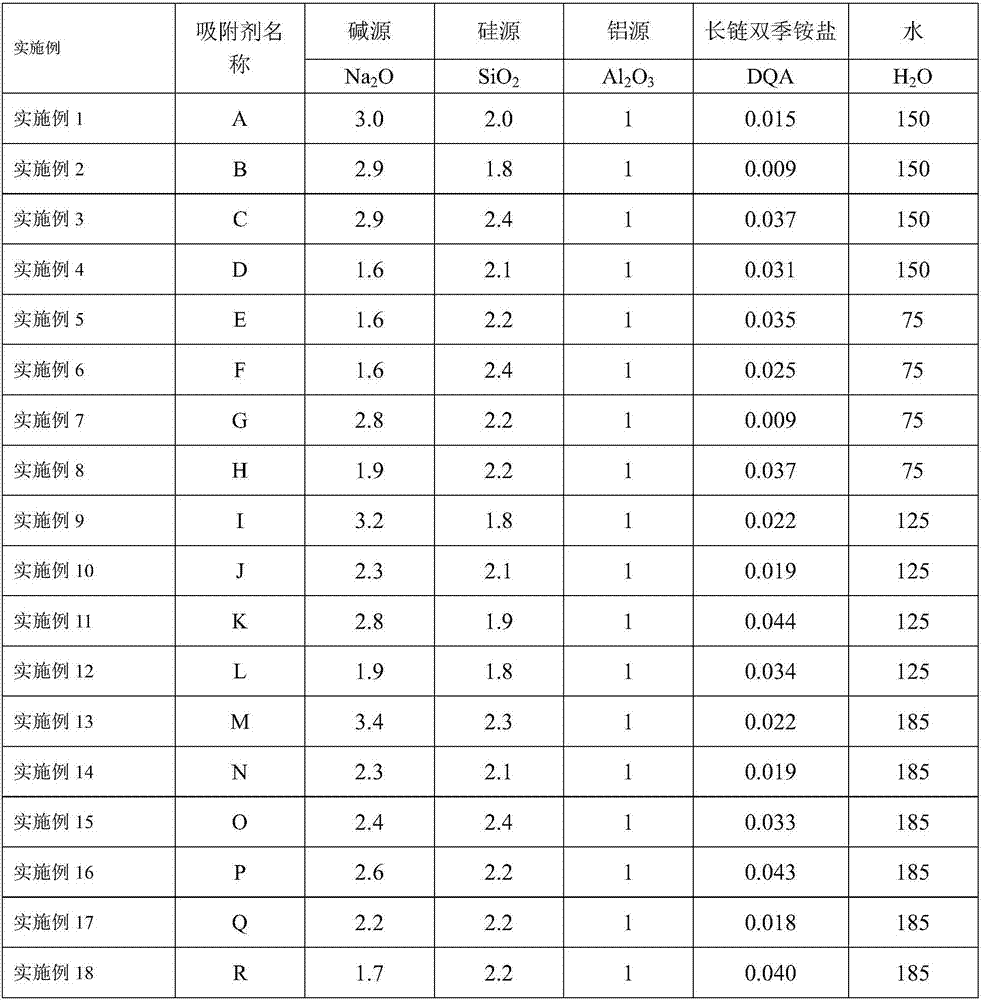

Multi-stage pore 5A molecular sieve adsorbent for n-alkane adsorption separation and preparation method thereof

PendingCN106914223AAdsorption equilibrium time is shortImprove adsorption and separation efficiencyOther chemical processesHydrocarbon oils refiningAlkaneSorbent

The invention discloses a multi-stage pore 5A molecular sieve adsorbent for n-alkane adsorption separation and a preparation method thereof. The preparation method comprises adding a long-chain double biquaternary ammonium salt as a soft template agent into a silicon source-aluminum source mixed sol system, carrying out hydrothermal synthesis to obtain a microporous-mesoporous structure multi-stage pore 4A molecular sieve, removing the soft template agent in the 4A molecular sieve, rolling to mold the 4A molecular sieve and a binder so that small particles having diameters of 0.2-0.8mm are obtained, carrying out drying and calcination, and carrying out calcium ion exchange and activation to obtain a microporous-mesoporous structure multi-stage pore 5A molecular sieve, wherein a ratio of the 5A molecular sieve in the adsorbent is 90-97wt% and a ratio of the binder is 3-10%. In the preparation method of the adsorbent, the multi-stage pore 5A molecular sieve has a high equilibrium adsorption capacity of n-alkane, improves a diffusion coefficient of the n-alkane in the molecular sieve and improves an adsorption separation rate.

Owner:CHINA CATALYST HLDG CO LTD

Magnetic prussian blue material, preparation thereof, and applications of magnetic prussian blue material in adsorption of cesium ions

ActiveCN110327899AEasy to prepareMild reaction conditionsOther chemical processesAlkali metal oxides/hydroxidesDouble bondFatty acid

The invention relates to a magnetic prussian blue material, a preparation thereof, and applications of the magnetic prussian blue material in adsorption of cesium ions. The preparation method comprises following steps: under the effect of a thermal initiator, Fe3O4 nanometer particles and a pyridine compound containing carbon-carbon double bonds, a nonsaturated aromatic hydrocarbon, and an oil soluble crosslinking agent are reacted in water, and polymer coated magnetic nanometer particles are obtained after reaction, wherein the surfaces of the Fe3O4 nanometer particles are modified with double-layer fatty acid; the magnetic nanometer particles and pentacyano mon-ammine ferroate are subjected to ligand exchange reaction so as to obtain the magnetic prussian blue material. The magnetic prussian blue material can be used for adsorption on cesium ions in soil, especially in clay; the magnetic prussian blue material and cationic chitosan are combined for pre-treatment of clay, the adsorption efficiency on cesium ion is high, and soil high efficiency purifying can be realized.

Owner:SUZHOU UNIV

A Metal Chelate Affinity Chromatography Medium Containing Rejection Layer

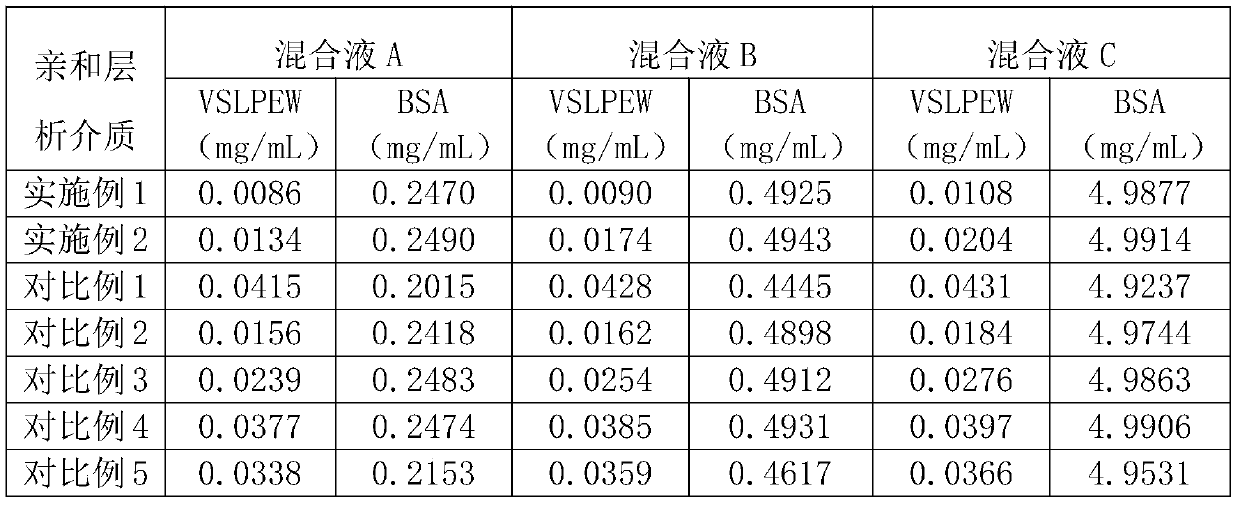

ActiveCN107754768BHigh hardnessGood adhesion and adsorptionOther chemical processesSolid sorbent liquid separationMicrosphereMetal chelate

The invention relates to a metal-chelating affinity chromatography medium containing a resistant layer. The preparation method comprises the following steps: by taking macroporous silica microspheresas a core, filling a mixture composed of three components, namely sodium alga acid, chitosan oligosaccharide and silicon nitride, in pore channels of the microspheres, bonding epoxy chloropropane ontothe core surface, connecting the epoxy chloropropane and a ligand, and complexing the ligand and metal ions; and adhering amylose to form the resistant layer on the core surface, wherein a mass ratioof the epoxy chloropropane to the amylose is 1:(4-5). According to the resistant layer, blocking of nonspecific macromolecules is realized, nonspecific adsorption is reduced, and the adsorption and separation efficiency on target micro-molecule polypeptides is improved.

Owner:SUZHOU BOJIN BIOLOGICAL TECH

Metal organic framework adsorbent with subvalent metal node prepared by steam reduction method as well as preparation method and application of metal organic framework adsorbent

PendingCN112844319AImprove complexation abilityLarge adsorption capacityOther chemical processesCarbon monoxideAlkaneMetal-organic framework

The invention discloses a metal organic framework adsorbent with a subvalent metal node prepared by a steam reduction method as well as a preparation method and application of the metal organic framework adsorbent. The metal organic framework adsorbent is characterized in that the metal organic framework adsorbent is of a porous structure of a three-dimensional network which is prepared by loading the subvalent metal node and self-assembling the subvalent metal node and an organic ligand containing carboxylic acid, imidazole, pyrimidine or pyridine. The prepared metal organic framework adsorbent with the subvalent metal nodes is directly used for adsorption desulfurization of fuel oil, separation of olefin and alkane and recovery of carbon monoxide. The invention provides the metal framework adsorbent which is large in adsorption capacity and high in selectivity and adsorption separation efficiency.

Owner:NANJING UNIV OF TECH

Magnetic andrographolide imprinted polymer as well as preparation method and application thereof

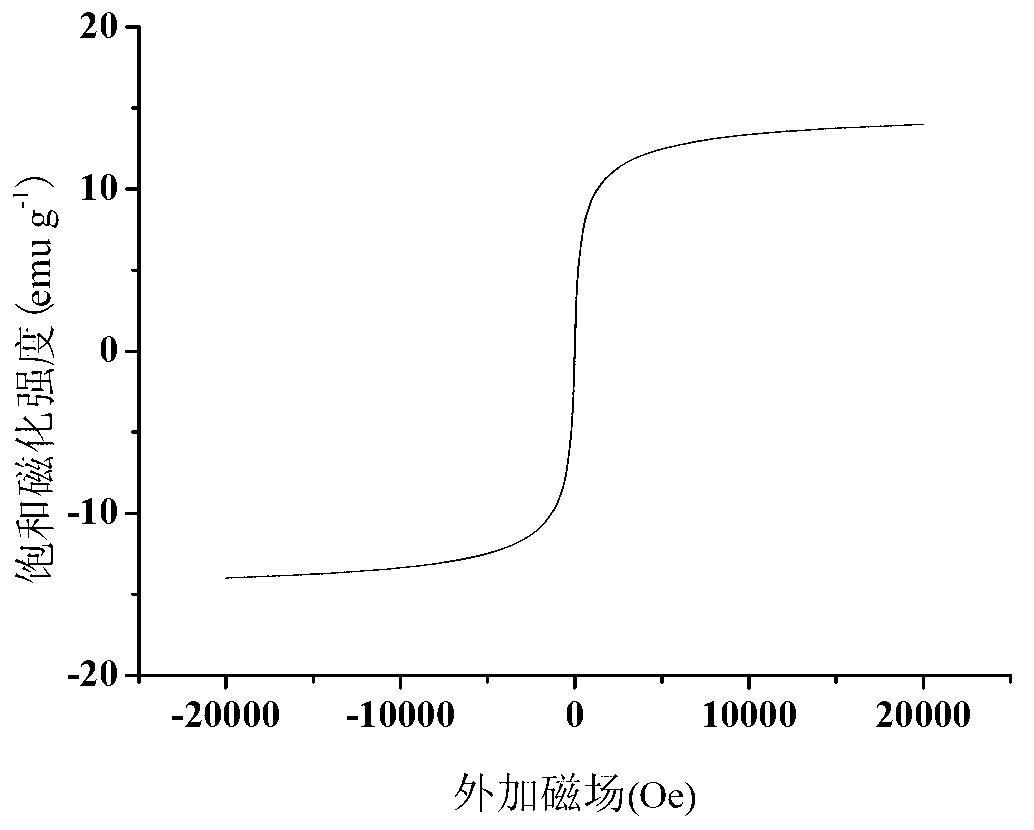

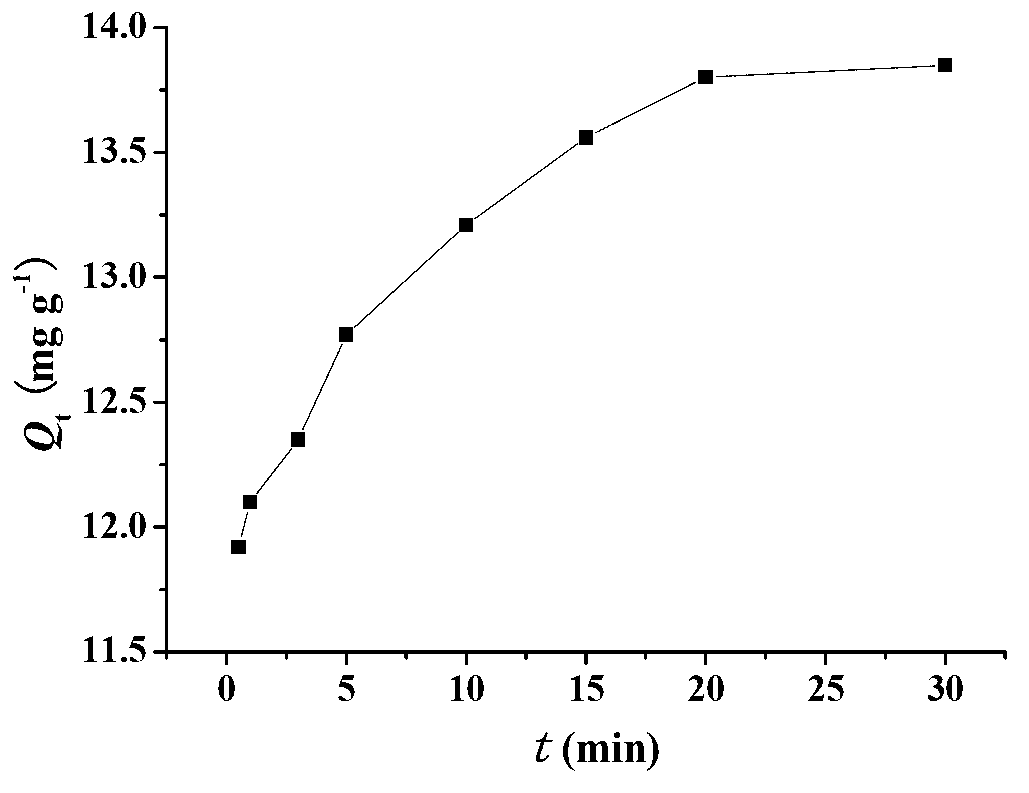

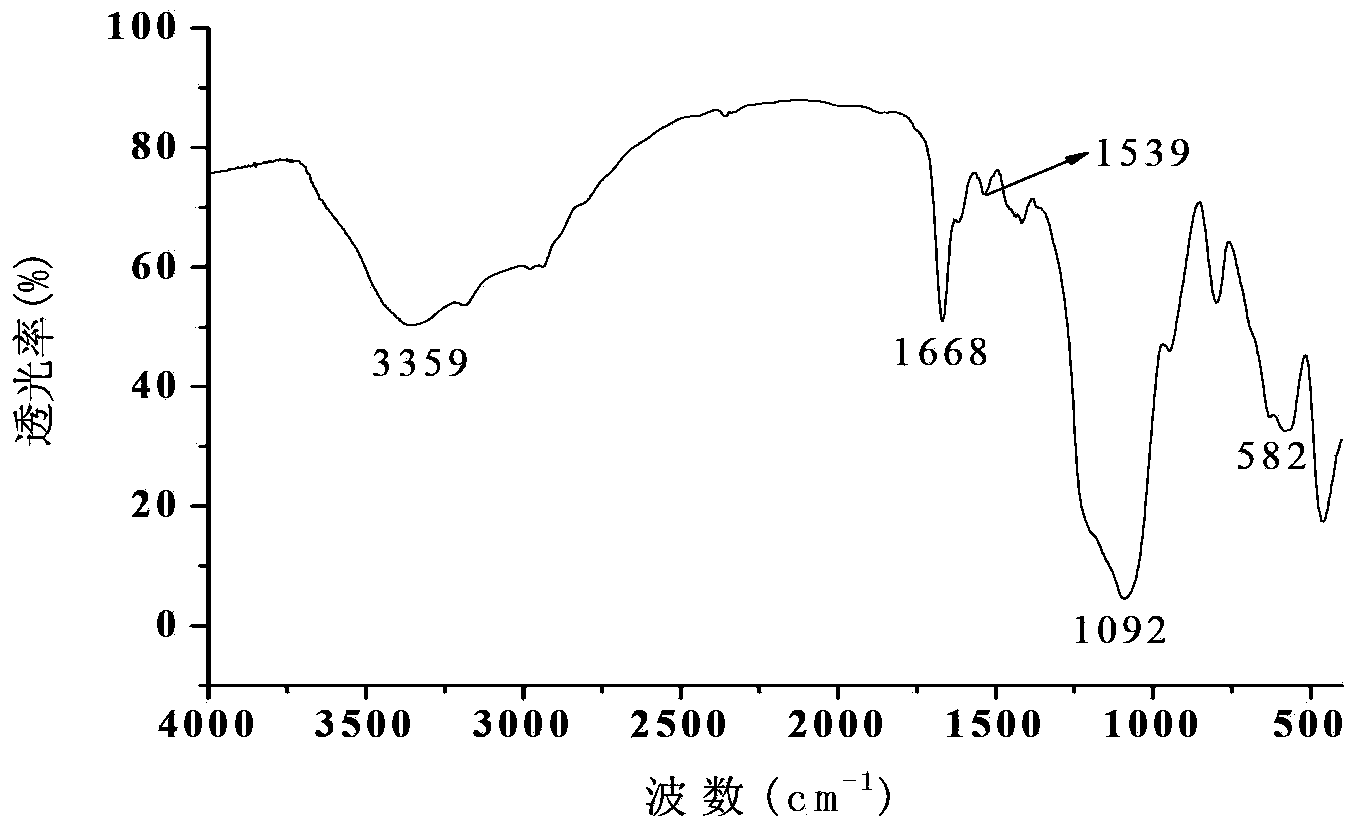

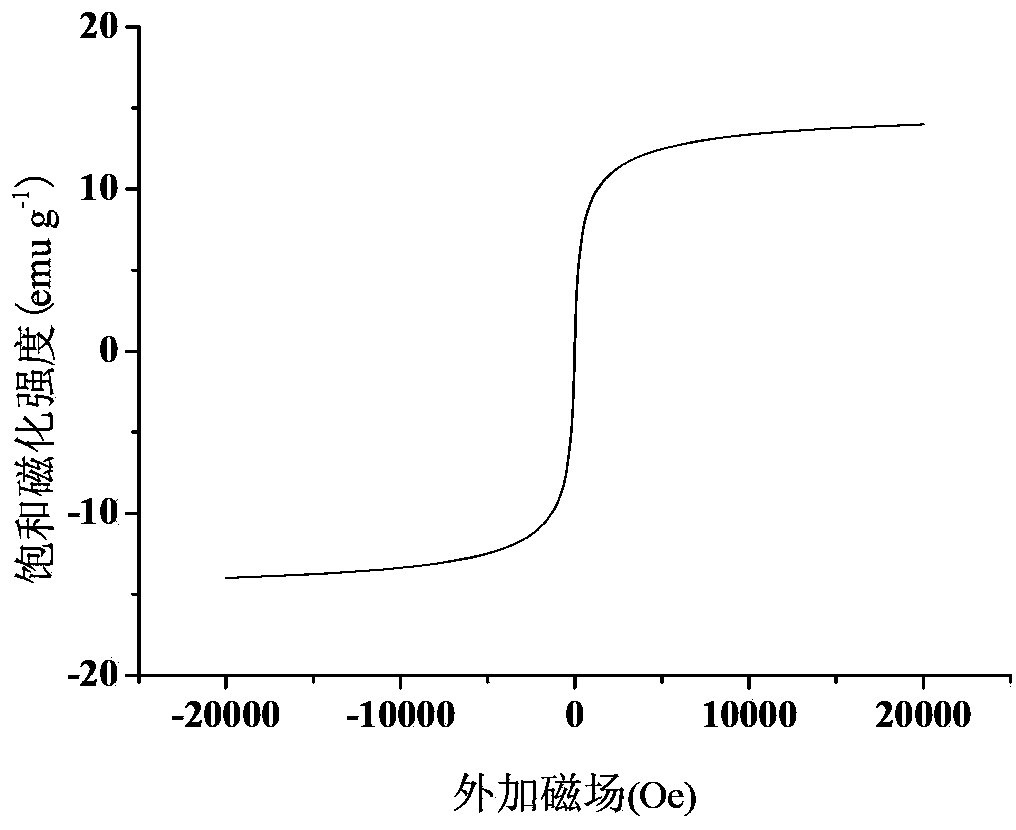

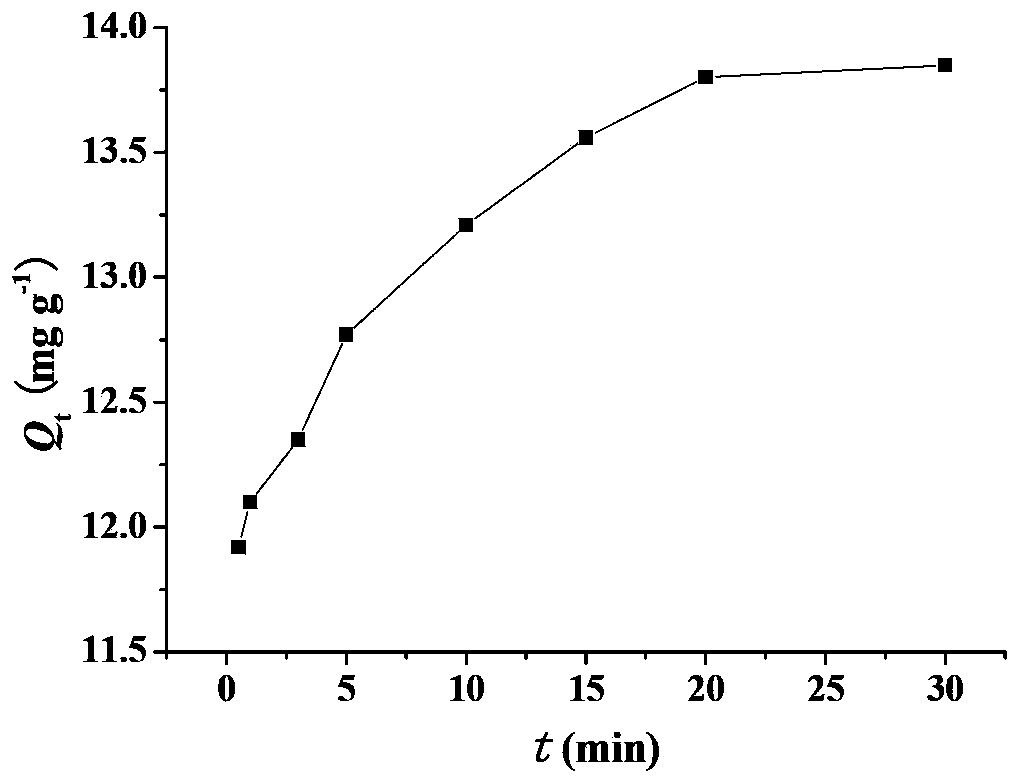

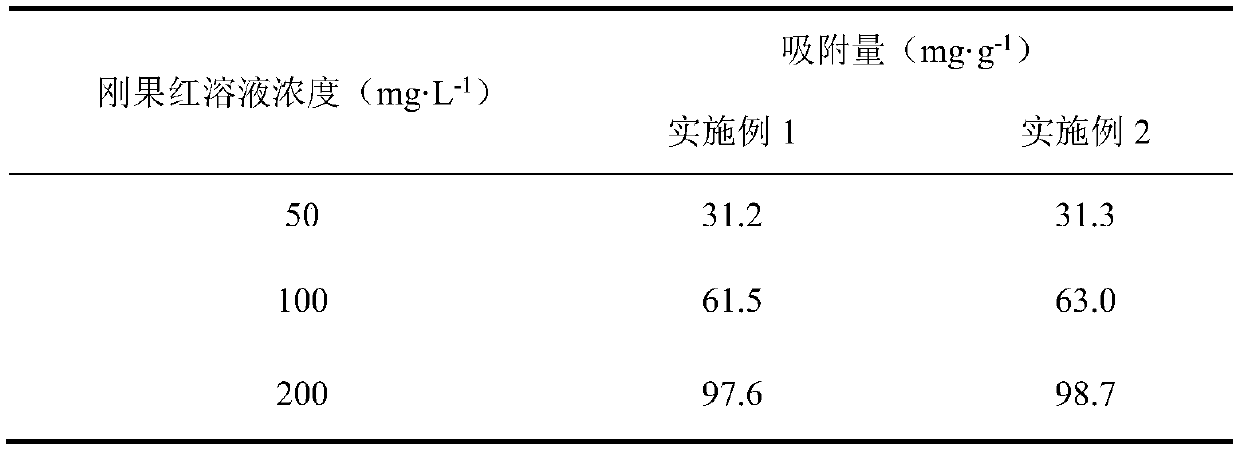

PendingCN113861358ARapid separation and enrichmentImprove adsorption and separation efficiencyOther chemical processesPolymer scienceAdsorption equilibrium

The invention discloses a magnetic andrographolide imprinted polymer and a preparation method and application thereof. The preparation method comprises the steps of: adding andrographolide and a monomer into an organic solvent for pre-assembly, then adding the pre-assembly body into a reversed-phase micro-emulsion system containing modified Fe3O4 magnetic nanoparticles, finally adding a cross-linking agent and an initiator, carrying out polymerization reaction at 30-60 DEG C for 25-28 hours, and then removing andrographolide to obtain the magnetic andrographolide imprinted polymer. The magnetic andrographolide imprinted polymer prepared by the method has the advantage that the andrographis paniculata adsorption speed is high, and adsorption equilibrium can be achieved in a short time. The polymer prepared by the method has good magnetism. When the polymer is used for extracting and separating andrographolide, the operation is simpler and more convenient. Selective separation is realized, and a higher recovery rate is obtained.

Owner:CHENGDU TONGDE PHARMA

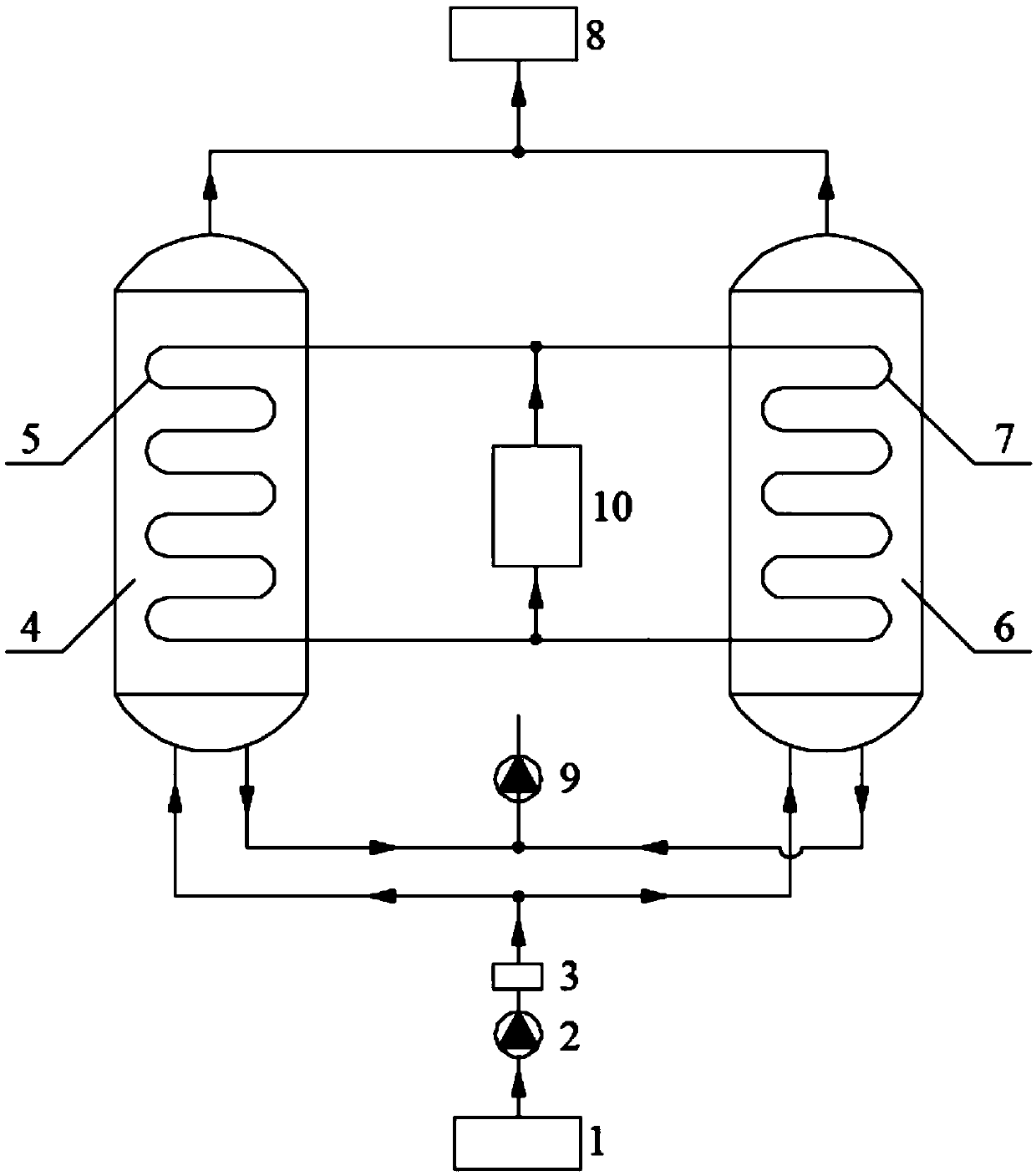

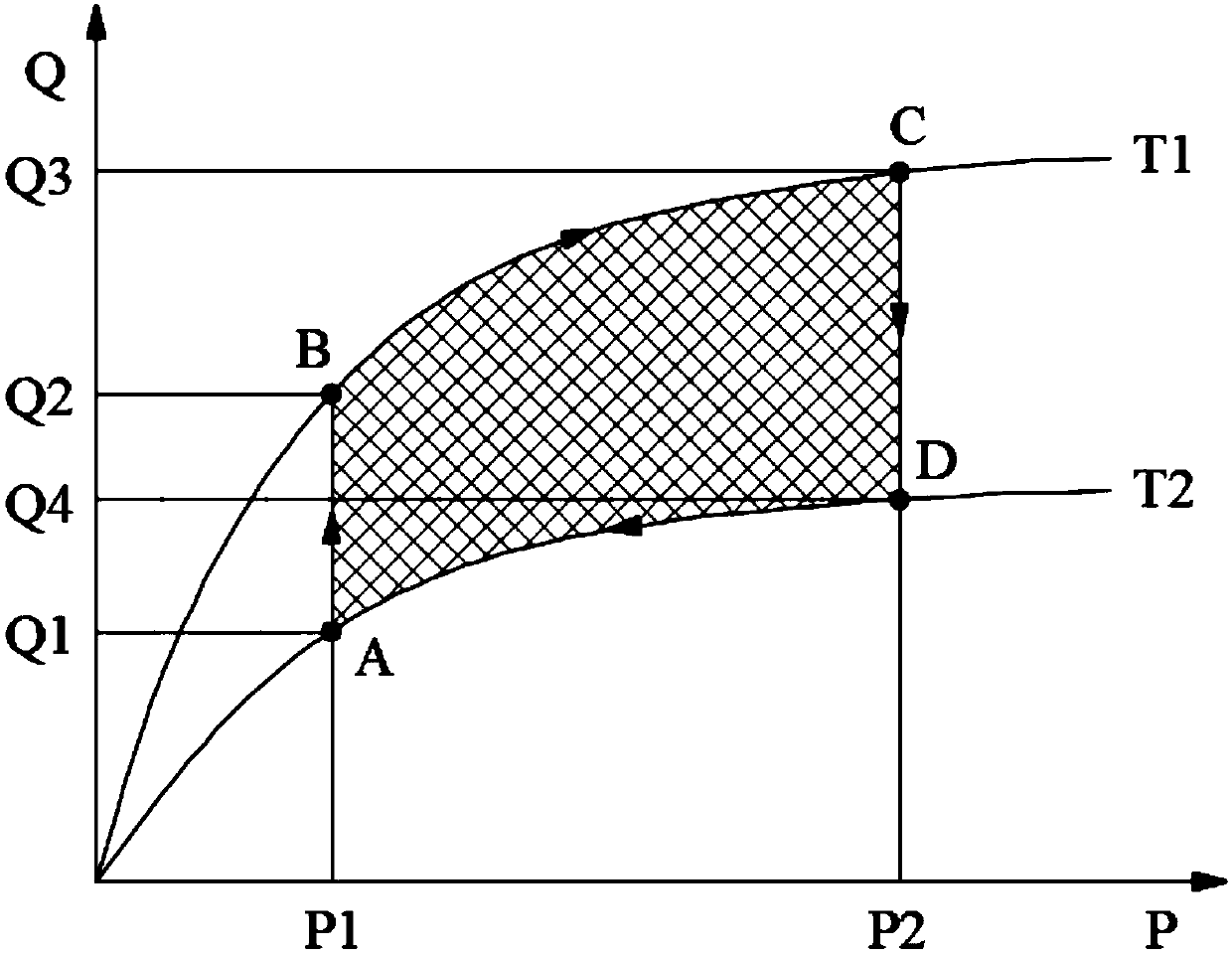

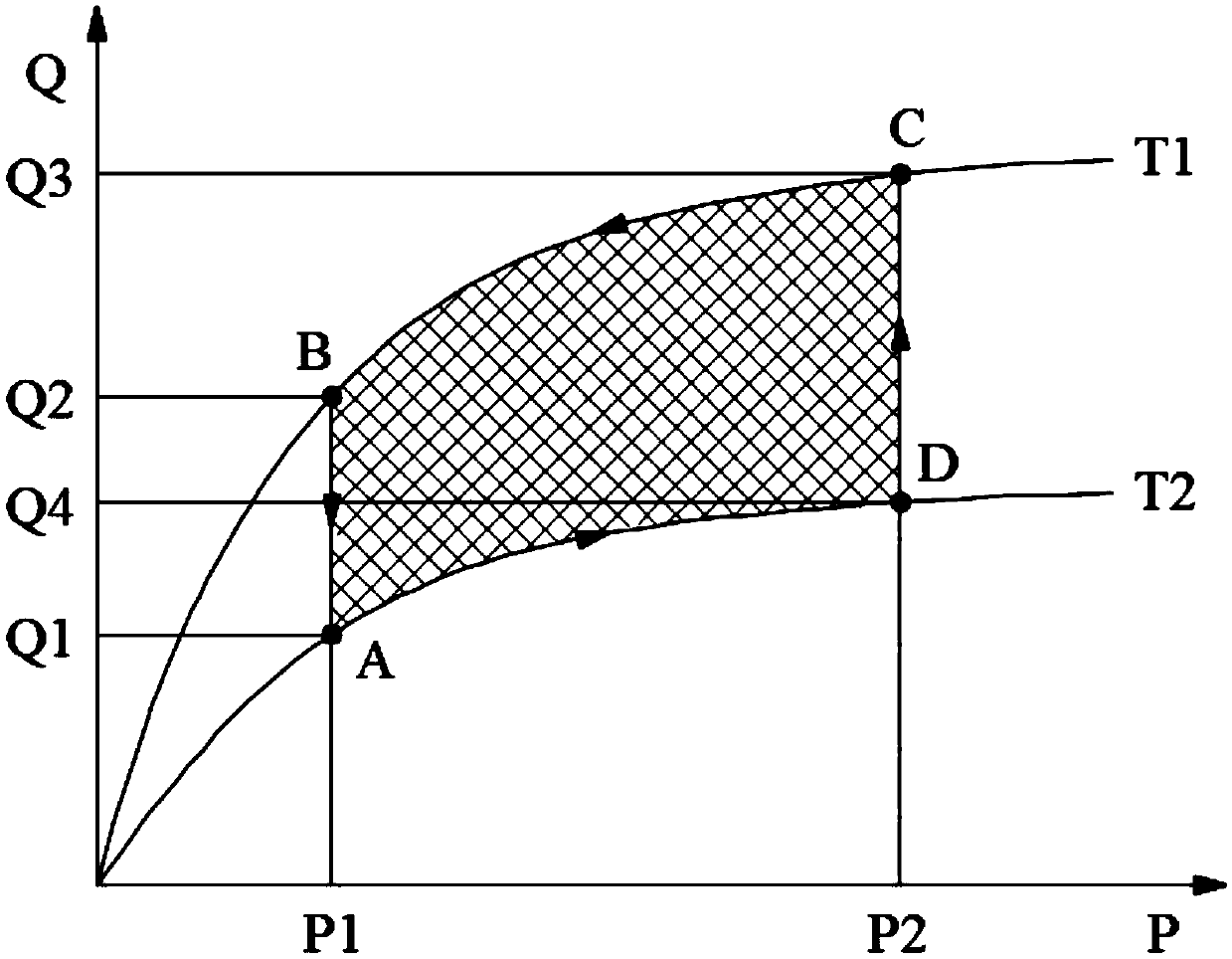

Temperature-pressure synergy adsorption separation purification method for gases

PendingCN109609223ALarge adsorption capacityHigh selectivity of adsorptionGas treatmentMethane capturePurification methodsHigh energy

The invention discloses a temperature-pressure synergy adsorption separation purification method for gases. Through a plurality of modes of temperature-pressure synergy circulation among different working conditions such as a high-temperature low-pressure adsorption point, a low-temperature low-pressure adsorption point, a low-temperature high-pressure adsorption point and a high-temperature high-pressure adsorption point, efficiency of separating gases by traditional pressure swing adsorption is improved. The method disclosed in the invention solves the problems of higher energy consumption,a lower product yield and insufficient utilization of system energy in the process of purifying and preparing the gases by the pressure swing adsorption, especially solves the condition that a mixed gas contains components difficult to separate, such as methane and nitrogen, and is especially suitable for comprehensive utilization of low-concentration gas and ventilation gas in coal mining.

Owner:CHINA UNIV OF MINING & TECH

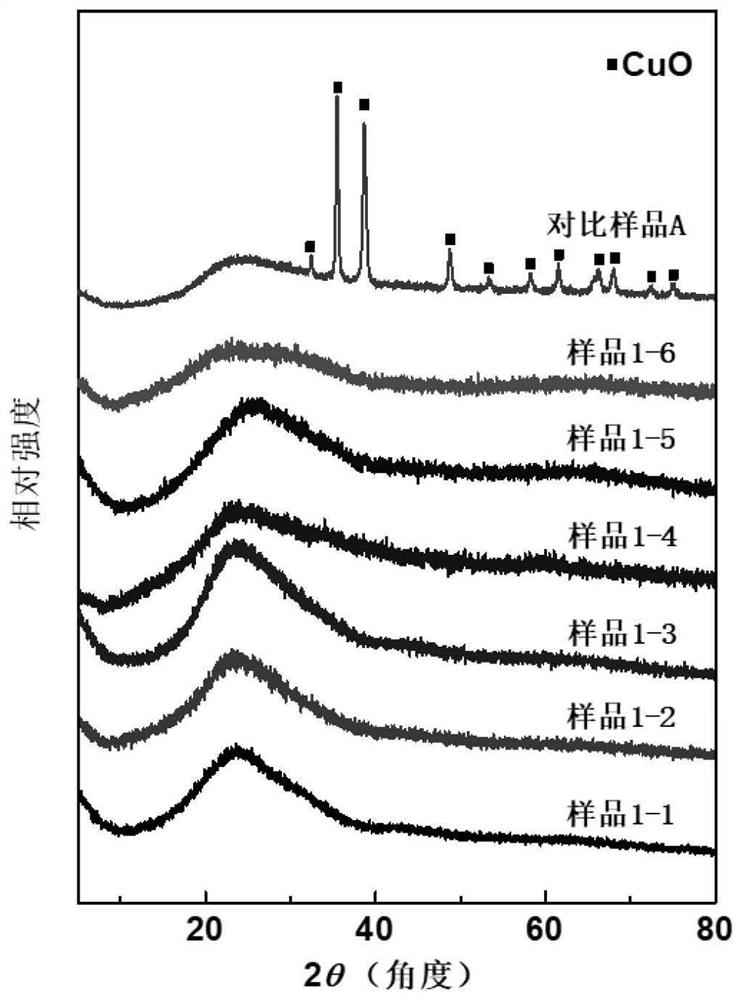

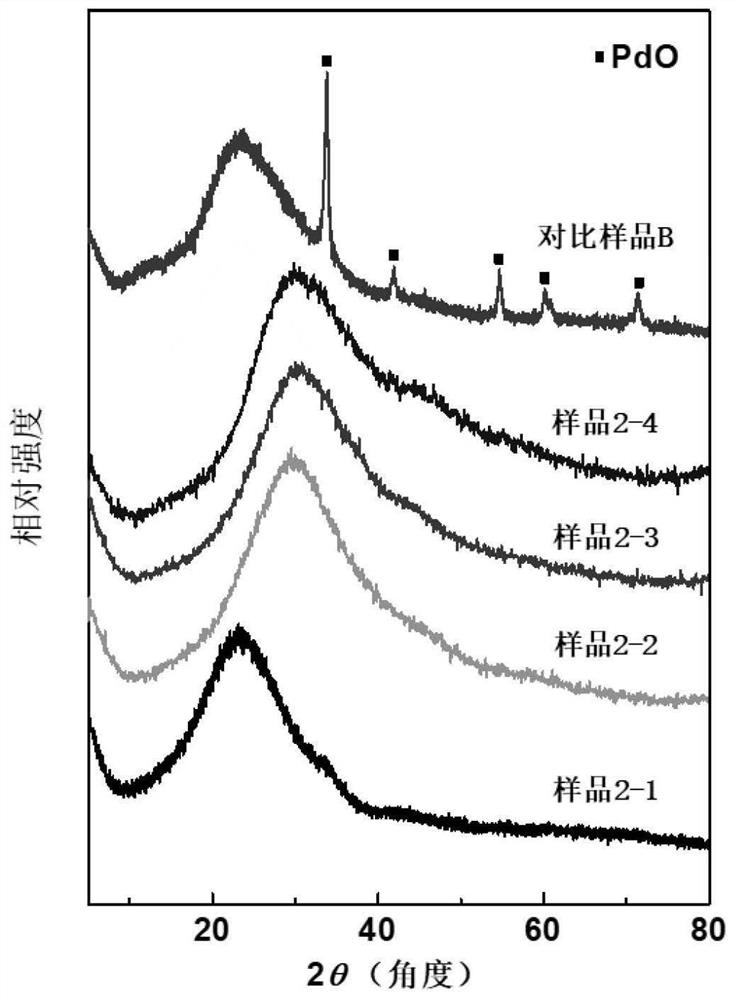

A highly dispersed metal or metal oxide doped adsorbent, preparation method and application thereof

ActiveCN112844317BImprove complexation abilityHigh selectivityOther chemical processesCarbon monoxidePhysical chemistryAdsorption separation

The invention discloses a highly dispersed metal or metal oxide doped adsorbent, a preparation method and its application. The preparation method comprises using porous metal oxide or a two-dimensional material as a carrier; loading a metal-organic polyhedron on the carrier, A metal-organic polyhedral loaded porous material is obtained; the loaded porous material is reduced or oxidized to obtain a highly dispersed metal or metal oxide doped adsorbent; wherein the metal or metal oxide includes Pd, Rh, Cu, One or more of Zr or Zn and their oxides, the content of the metal or metal oxide is 0.1-6 mmol / g. The present invention uses the metal-organic polyhedron as the active site precursor to prepare a highly dispersed metal or metal oxide doped adsorbent, the method is simple, and due to the limitation of the number of metal nodes in the metal-organic polyhedron, the adsorption capacity of the metal or metal oxide is significantly improved. The degree of dispersion significantly enhances the complexing ability of active sites, thereby significantly improving its adsorption and separation performance.

Owner:NANJING TECH UNIV

Method for efficiently reducing granularity of 5A molecular sieve (MS)

ActiveCN103007878BSmall granularityGuaranteed microporous structureOther chemical processesDispersed particle separationMolecular sieveGranularity

The invention relates to a method for efficiently reducing granularity of a 5A molecular sieve (MS). The method comprises the following steps of: (1) adding a duct proppant to the 5A MS; (2) dispersing the 5A MS in a dispersing agent to prepare an MS suspension; (3) selecting a grinding medium; (4) setting grinder parameters; and (5) adding the MS suspension and the grinding medium to a grinder to be ground. The method has the advantages that under the condition of keeping the adsorption quantity of the 5A MS changeless, the granularity of the MS is reduced, the adsorption cycle of the 5A MS for producing nitrogen through pressure swing adsorption (PSA) is shortened, the yield of high purity nitrogen is obviously increased, and the economic benefits of nitrogen production through PSA of the MS are increased.

Owner:天津众智科技有限公司

Methods for preparing and using sudan red magnetic molecularly imprinted polymer

InactiveCN103059206BImprove magnetic propertiesFacilitate adsorption and separationOscillatory reactionElution

The invention relates to methods for preparing and using a sudan red magnetic molecularly imprinted polymer. The methods aim to solve the problems that the conventional separated / purified sudan red I magnetic molecularly imprinted polymer has a 'solution polymerization' phenomenon in the synthesis process and the obtained separated / purified sudan red I magnetic molecularly imprinted polymer has a non-uniform spatial network structure. The preparation method comprises the following steps of: 1, preparation of Fe3O4; 2, preparation of magnetic SiO2; 3, preparation of aminated magnetic SiO2; 4, preparation of initiator / magnetic SiO2; and 5, polymerization reaction. The using method comprises the following steps of: adding the sudan red magnetic molecularly imprinted polymer into a sample solution containing sudan red, and then sequentially performing oscillatory reaction, magnetic separation and elution. The method is mainly used for preparing the sudan red magnetic molecularly imprinted polymer.

Owner:NORTHEAST FORESTRY UNIVERSITY

A kind of extraction method of polyphenols in sugarcane scum

ActiveCN106220690BSolve the problem of decolorizationResolve continuityOrganic chemistryPlant ingredientsHigh concentrationAlcohol

The invention belongs to the technical field of plant component extraction, and discloses a method for extracting polyphenols from sugarcane scum. The extraction method is as follows: using sugarcane scum as a raw material, extracting with an ethanol solution under the condition of ultrasonic assistance, adding absolute ethanol to the obtained extract, resting for 12h-48h at 2°C to 5°C, and separating and collecting the upper layer solution; The obtained upper layer solution is concentrated and then adsorbed and eluted by a macroporous resin to obtain a polyphenol eluate; finally, the polyphenol eluate is concentrated and dried to obtain the final product polyphenol. The invention adopts the low-temperature high-concentration alcohol precipitation technology to remove a large amount of macromolecular substances in the extracted filtrate, improves the adsorption and separation efficiency of the macroporous resin to the polyphenol, and can significantly reduce the production cost.

Owner:广东省科学院生物与医学工程研究所

High-performance adsorption film based on ZIFs material

InactiveCN110681358AImprove adsorption capacityHigh removal rateOther chemical processesAlkali metal oxides/hydroxidesCoated membraneAdsorptive membrane

The invention discloses a specific method for rapidly preparing a ZIFs adsorption film by using a vapor phase growth method. The preparation method comprises: coating the surface of a base film with acobalt / zinc-based sol, putting the base film into a drying oven, heating and aging to obtain a cobalt / zinc-based gel coating film, and carrying out a reaction on the cobalt / zinc-based gel coating film and a 2-methylimidazole gas-phase ligand through a gas-phase growth method to prepare the ultrathin ZIFs adsorption film. According to the invention, the preparation method is simple in process, hascontrollability, and is expected to be further applied to preparation of other types of metal organic framework material adsorption films.

Owner:BEIJING FORESTRY UNIVERSITY

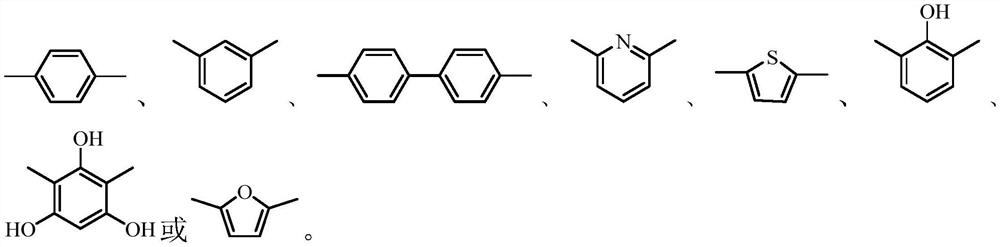

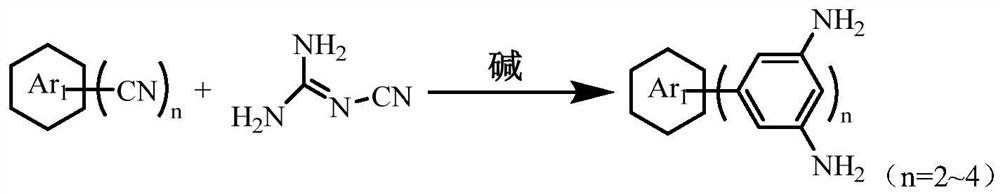

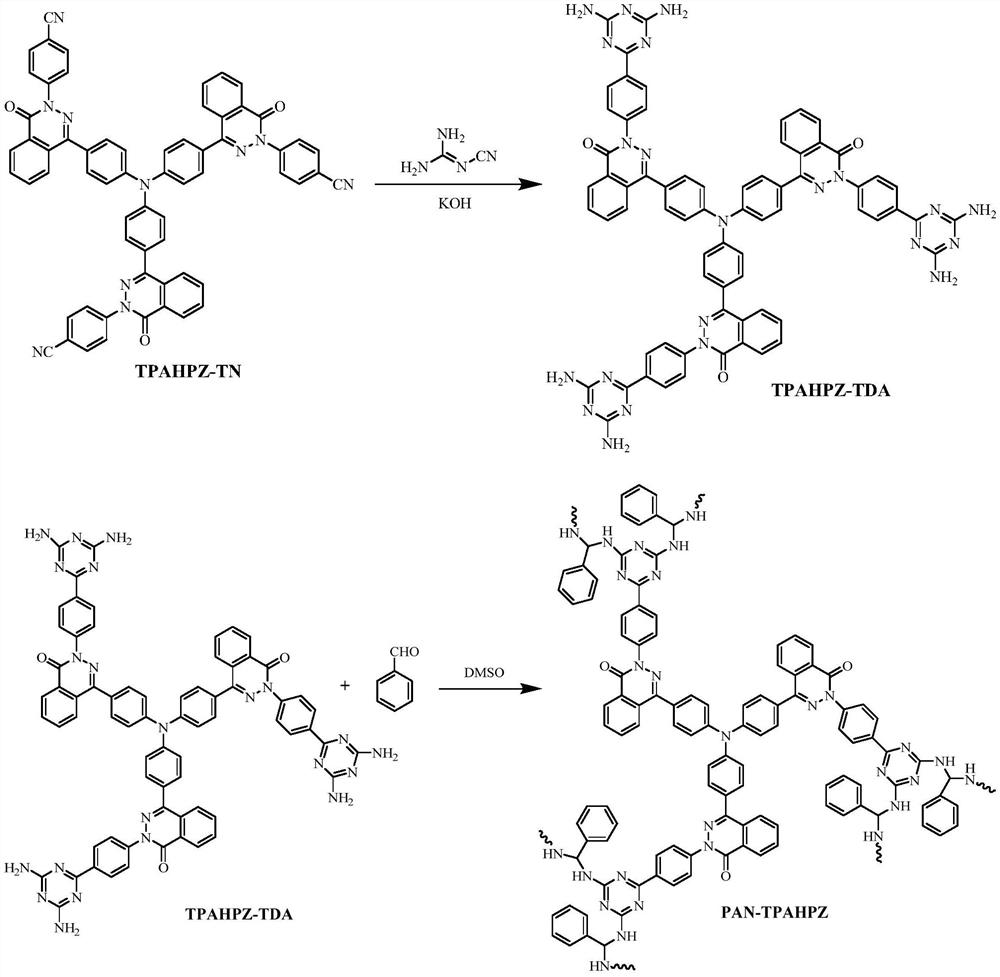

Nitrogen-rich porous polymer containing heteroatom, imine and triazine ring structure and preparation method

ActiveCN111285986BImprove adsorption capacityLarge specific surface areaGas treatmentOrganic chemistryHomogeneous catalysisChemical stability

Owner:DALIAN UNIV OF TECH

Method for Simulated Moving Bed Adsorption and Separation of Paraxylene in C8 Aromatics

ActiveCN108017502BImprove adsorption and separation efficiencyAdsorption purification/separationDiethyl benzeneDesorption

A method for adsorbing and separating p-xylene from C8 aromatics in a liquid-phase simulated moving bed, comprising feeding the C8 aromatics raw material into the simulated moving bed to absorb the p-xylene therein, obtaining a raffinate, and feeding it into the adsorption bed The desorbent desorbs the adsorbed p-xylene, obtains the extract and discharges it from the simulated moving bed, and the material entering and leaving the simulated moving bed divides the adsorption bed into a desorption area, a purification area, an adsorption area and an isolation area. The active component of the adsorbent is BaX or BaKX zeolite, and the desorbent is p-diethylbenzene. The temperature of the C8 aromatics raw material entering the simulated moving bed adsorption bed is controlled at 100-155°C, and the desorption of the simulated moving bed adsorption bed is carried out. The agent temperature is 170-210°C. The method can improve the separation efficiency of the simulated moving bed separation process of p-xylene in C8 aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of modified alumina dehydrating agent

ActiveCN103706324BHigh strengthLarge hole volumeOther chemical processesDispersed particle separationSorbentCatalytic oxidation

The invention discloses a preparing method of a modified aluminum oxide dehydrant. The preparing method comprises the following steps: uniformly blending alumina gel, silica gel, calcium oxide, zinc oxide and sesbania and carrying out kneading, molding, granulating, primary drying, primary roasting, impregnating, secondary drying and secondary roasting in sequence to prepare finished products, carrying out dehydration process before chlorine and oxygen are separated from the mixed gas generated by catalytic oxidation reaction of hydrogen chloride by using adsorption separation method, the mass ratios of alumina gel to silica gel to calcium oxide to zinc oxide to sesbania are (70-82):(7-14):(0.5-2.0):(5-10):(5-10). In the preparing method, water absorption drying agent which is allowed to be used in chlorine-containing gas with small amount of water, and can form the compound absorption bed layer together with the silica gel, the compound bed absorption agent is arranged at the gas outlet end of the compound absorption bed layer to deeply dry and dehydrate gas.

Owner:FININGS CO LTD

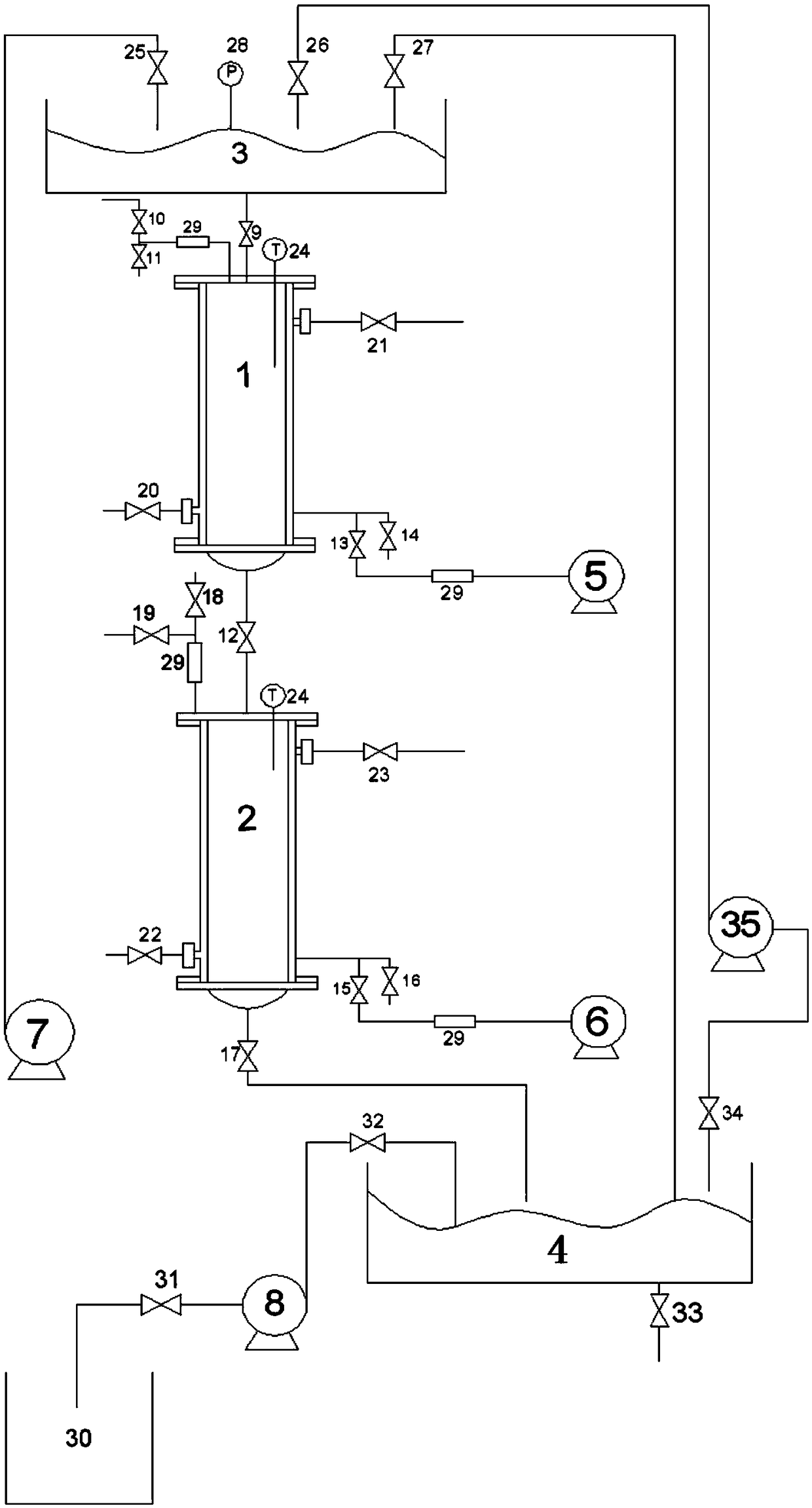

An automatic column-loading continuous operation series macroporous resin adsorption separation device

ActiveCN106422414BSolve the problem of manual column packingSave human effortSolid sorbent liquid separationHigh pressure waterHigh pressure

The invention discloses an automatic-column-mounting continuous-operating in-series macroporous resin adsorption and separation device. The automatic-column-mounting continuous-operating in-series macroporous resin adsorption and separation device comprises an adsorption column and a resolving column. The adsorption column is connected with the resolving column in series. A high-position quantification tank is connected to the top of the adsorption column. An upper sample liquid circulating pump is connected to the lower portion of the adsorption column. A vacuuming opening is formed in the upper portion of the high-position quantification tank, and is used for being connected with a vacuum pump. A water inlet is formed in the upper portion of the high-position quantification tank, and is connected with a high-pressure water pump. The lower portion of the resolving column is connected with an eluent circulating pump and a resin recycling pool. The upper portion of the resin recycling pool is connected with a regenerated liquid circulating pump. The high-position qualification tank is communicated with the resin recycling pool through a connector. The automatic-column-mounting continuous-operating in-series macroporous resin adsorption and separation device has the advantages that the problem of manual column mounting for a long time is solved, manpower is saved, continuous operation in the whole process of adsorption, resolution and regeneration is realized through resin transport, and adsorption and separation efficiency is improved.

Owner:TIANJIN UNIV OF TRADITIONAL CHINESE MEDICINE

Preparation and application method of carbon nanotube-based magnetic bactericide molecularly imprinted polymer

ActiveCN105693961BFast adsorptionRaw materials are easy to getIon-exchange process apparatusOther chemical processesFiltrationMolecularly imprinted polymer

The invention provides preparation and application methods of a carbon-nanotube-base magnetic bactericide molecularly-imprinted polymer, relating to preparation and application methods of bactericide molecularly-imprinted polymers. The invention aims to solve the problems of time consuming, high organic solvent consumption and low selectivity in the sample pretreatment technique in the existing bactericide residue analysis, the problem of the solution polymerization phenomenon in the existing bactericide molecularly-imprinted polymer synthesis process, and the problem that the solution separation process needs the vacuum filtration or centrifuging step. The preparation method comprises the following steps: 1. activating carbon nanotubes; 2. hydroxylating the carbon nanotubes; 3. preparing the magnetic carbon nanotubes; 4. preparing the initiator / magnetic carbon nanotubes; and 5. carrying out polymerization reaction. The application method comprises the following steps: adding the carbon-nanotube-base magnetic bactericide molecularly-imprinted polymer into a bactericide-containing sample solution, and sequentially carrying out oscillation, magnetic resolution and elution.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com