Special activated carbon for adsorption separation of chlorine gas and oxygen

A technology of adsorption separation and activated carbon, which is applied in the direction of oxygen production, chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A special activated carbon used for the adsorption and separation of chlorine and oxygen, comprising: the raw activated carbon is sequentially impregnated, dried, roasted and decomposed to make a finished product.

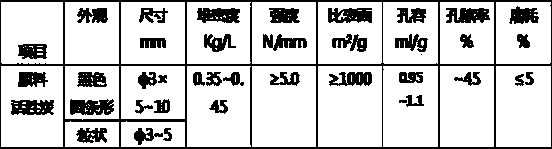

[0033] In this example, the physical properties of the special activated carbon are: bulk density 0.40~0.45 kg / L, strength ≥ 5.5 N / mm, specific surface ≥ 900 m 2 / g, pore volume 0.9~1.0 ml / g, abrasion ≤5%.

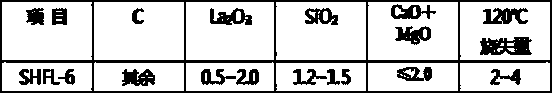

[0034] In the present embodiment, the chemical composition of the special activated carbon is: 0.5-2.0% by weight of La 2 o 3 , 1.2~1.5% SiO 2 , CaO+MgO≤2.0%, and the balance is C.

[0035] In this embodiment, the pressure of the special activated carbon is negative pressure, normal pressure—2.5MPa; the temperature of use is normal temperature—180°C.

[0036] In the present embodiment, the impregnation process is: impregnating La(NO 3 ) 3 The aqueous solution, the concentration is 5-12% (weight %); The immersion temperature is 50-80 ℃, and the imme...

Embodiment 2

[0040] A special activated carbon used for the adsorption and separation of chlorine and oxygen, comprising: the raw activated carbon is sequentially impregnated, dried, roasted and decomposed to make a finished product.

[0041] In the present embodiment, the chemical composition of described special-purpose activated carbon is: the La of 0.5% by weight percentage composition 2 o 3 , 1.2% SiO 2 , CaO+MgO≤2.0%, and the balance is C.

[0042] In the present embodiment, the impregnation process is: impregnating La(NO 3 ) 3 The aqueous solution, the concentration is 5% (weight %); The immersion temperature is 50 ℃, and the immersion time is 0.5 hours.

[0043] In this embodiment, the drying conditions are as follows: the drying temperature is 110° C., and the drying time is 1.0 hour.

[0044] In the present embodiment, the conditions of the calcination and decomposition are: inert gas (N 2 +Ar) ≥ 99.9% nitrogen protection heat treatment, the oxygen content in nitrogen ≤ 0.1...

Embodiment 3

[0046] A special activated carbon used for the adsorption and separation of chlorine and oxygen, comprising: the raw activated carbon is sequentially impregnated, dried, roasted and decomposed to make a finished product.

[0047] In the present embodiment, the chemical composition of the special activated carbon is: 2.0% La by weight 2 o 3 , 1.5% SiO 2 , CaO+MgO≤2.0%, and the balance is C.

[0048] In the present embodiment, the impregnation process is: impregnating La(NO 3 ) 3 The aqueous solution, the concentration is 12% (weight %); The immersion temperature is 80 ℃, and the immersion time is 1.0 hour.

[0049] In this embodiment, the drying conditions are as follows: the drying temperature is 120° C., and the drying time is 1.5 hours.

[0050] In the present embodiment, the conditions of the calcination and decomposition are: inert gas (N 2 +Ar) ≥ 99.9% nitrogen protection heat treatment, the oxygen content in nitrogen ≤ 0.10%, the calcination temperature is 500 ℃, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com