Method of recovering chlorine and oxygen from chlorine-containing oxygen-containing gas mixture

A technology of mixed gas and chlorine gas, applied in chemical instruments and methods, separation methods, chlorine/hydrogen chloride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

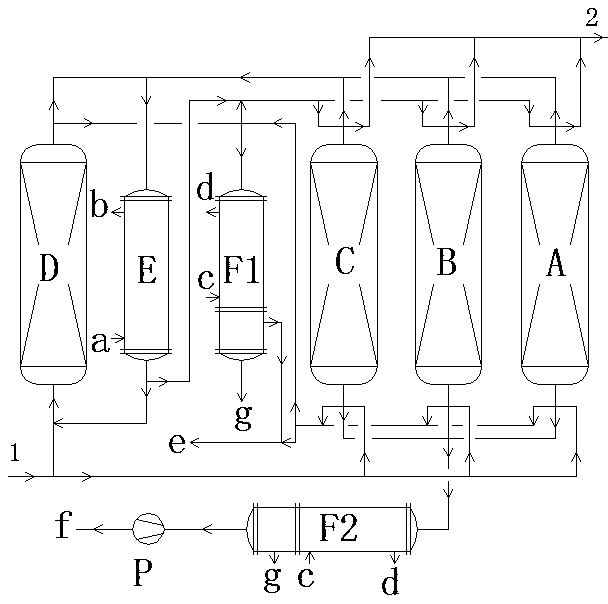

Embodiment 1

[0064] The mixed tail gas (feed gas of the present invention) after the product of hydrogen chloride oxidation reaction is absorbed by water to remove unreacted hydrogen chloride (existing production technology) enters the adsorption separation (drying) device to remove residual moisture in the tail gas: can Use a temperature swing adsorption drying device (or a pressure swing adsorption drying device) for drying and dehydration.

[0065] The adsorption tower is filled with a desiccant layer composed of two kinds of adsorbents. One adsorbent is modified SHFL-3 alumina dehydrating agent, and the other is dehydrated and dried 3A molecular sieve (or 5A molecular sieve, silica gel). SHFL -3 type alumina dehydrating agent is placed in the upper part of the adsorption tower, 3A molecular sieve or silica gel is placed in the lower part of the adsorption tower, the volume ratio of SHFL-3 and 3A molecular sieve (or 5A molecular sieve, silica gel) is 20~80% and 80% ~20%.

[0066] Durin...

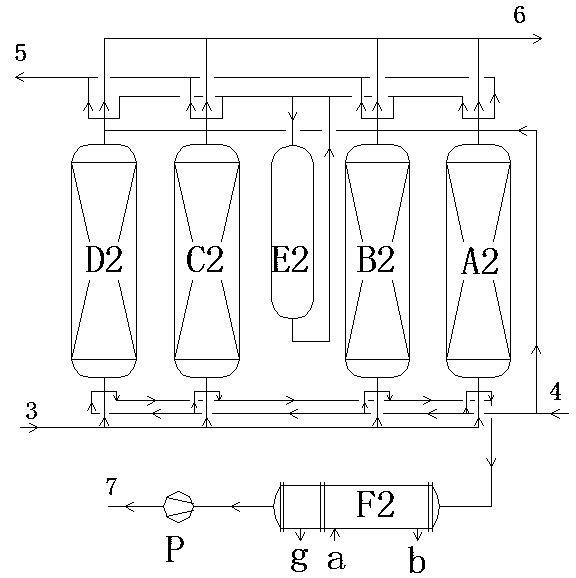

Embodiment 2

[0096] A method for recovering chlorine and oxygen from a mixed gas containing chlorine and oxygen, comprising: using the product of the hydrogen chloride oxidation reaction (Deacon reaction) to absorb the mixed tail gas after removing unreacted hydrogen chloride as a raw material gas, and pass through two Steps to separate:

[0097] a. The raw material gas is separated and dried by adsorption to remove the residual moisture in the tail gas;

[0098] b. The dry raw material gas after dehydration is separated by temperature and pressure swing adsorption to complete the separation of chlorine and oxygen. The purity of the separated and recovered chlorine gas reaches ≥99.5% (V.%) and the purity of oxygen reaches ≥99.5% (V.%), both of which can meet the quality requirements for direct use as process raw material gas.

[0099] In the step a, a temperature swing adsorption drying device is used, and a composite adsorbent layer composed of two kinds of adsorbents is used in the temp...

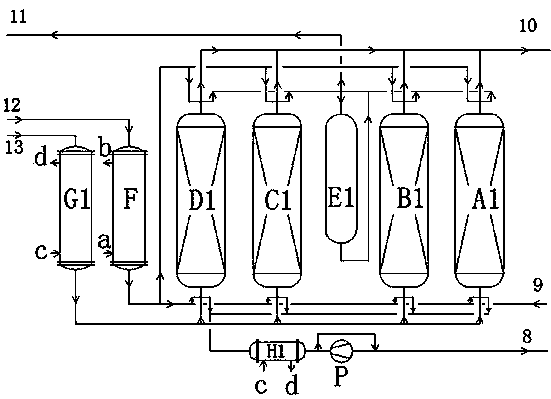

Embodiment 3

[0124] A method for recovering chlorine and oxygen from a mixed gas containing chlorine and oxygen, comprising: using the product of the hydrogen chloride oxidation reaction (Deacon reaction) to absorb the mixed tail gas after removing unreacted hydrogen chloride as a raw material gas, and pass through two Steps to separate:

[0125] a. The raw material gas is separated and dried by adsorption to remove the residual moisture in the tail gas;

[0126] b. The dry raw material gas after dehydration is separated by temperature and pressure swing adsorption to complete the separation of chlorine and oxygen.

[0127] In the step a, a temperature swing adsorption drying device is used, and a composite adsorbent layer composed of two kinds of adsorbents is used in the temperature swing adsorption drying process, one kind of adsorbent is an alumina dehydrating agent placed on the upper part of the adsorption tower, and the other It is an adsorbent placed in the lower part of the adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com