N-alkane adsorption and separation adsorbent and preparation method thereof

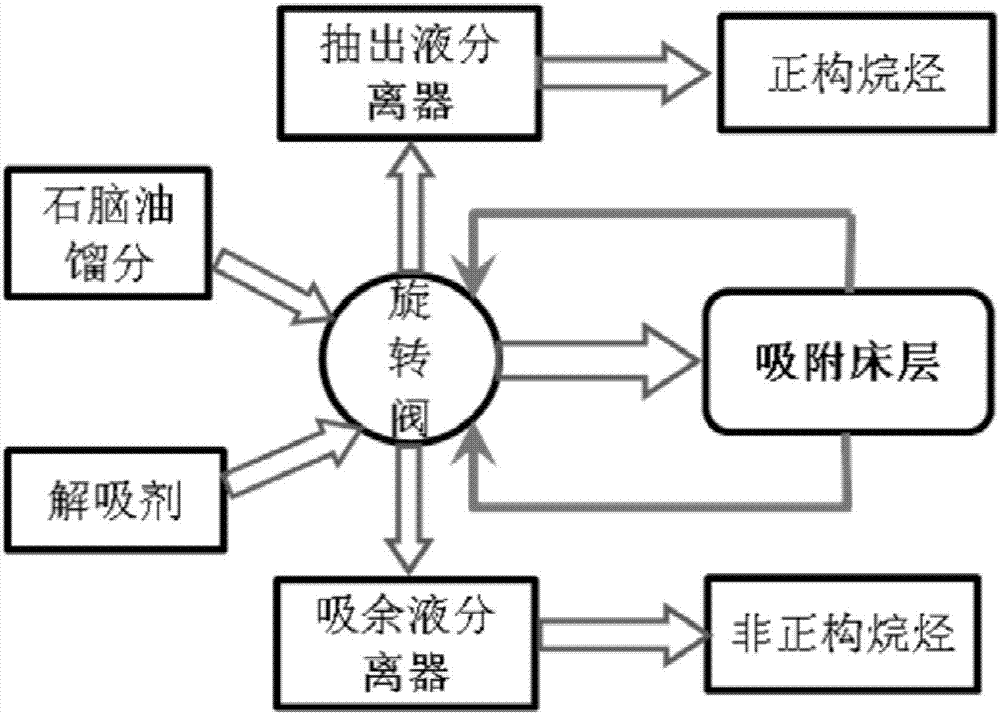

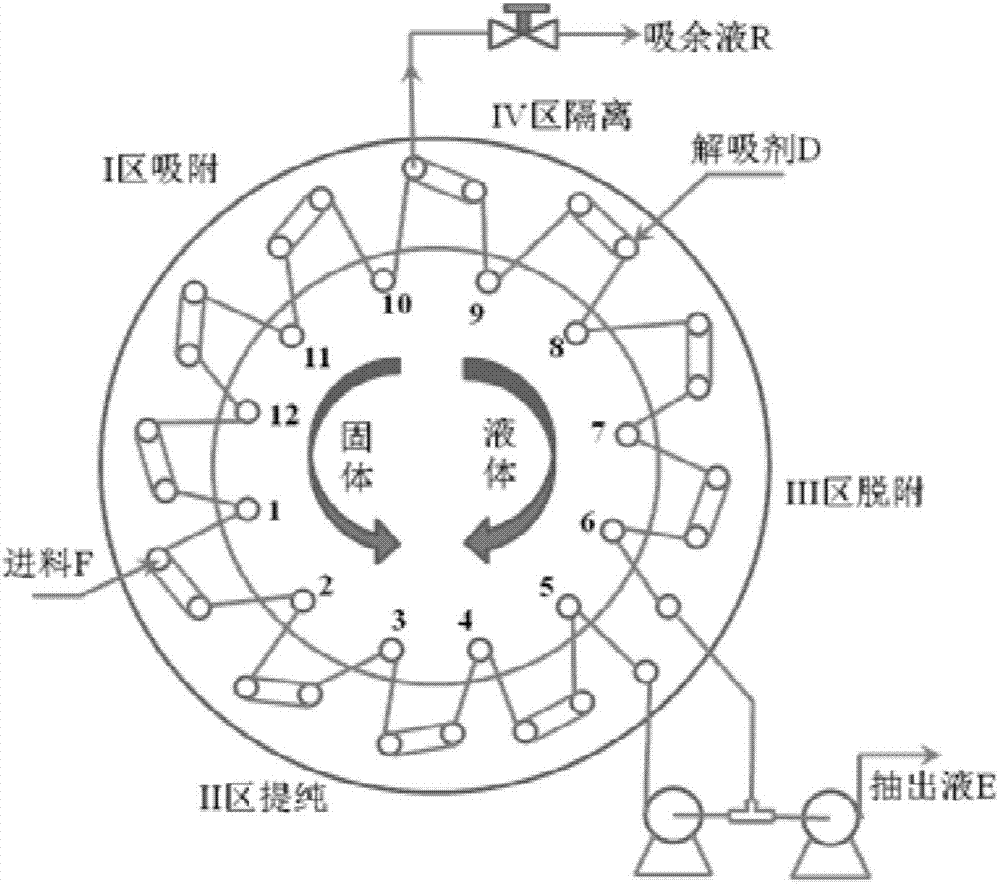

A technology for adsorption and separation of normal alkanes, which is applied in chemical instruments and methods, refined hydrocarbon oil, and other chemical processes, and can solve problems such as long diffusion paths, low active center utilization, and long adsorption/desorption cycles. To achieve the effect of improving the adsorption separation efficiency and the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

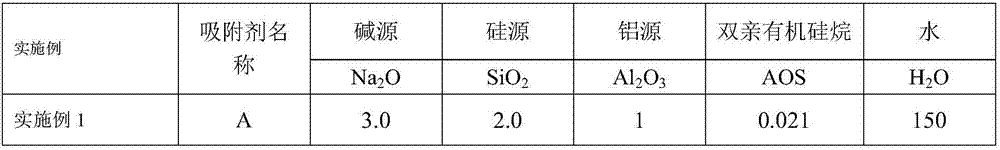

Embodiment 1

[0035] According to the following molar ratio of raw materials:

[0036] nNa 2 O:nSiO 2 :nAl 2 o 3 :nAOS:nH 2 O=3:2:1:0.021:150

[0037] Weigh the amphiphilic organosilane, silicon source solution, NaOH, aluminum source solution and deionized water and mix evenly,

[0038] Concrete synthetic steps are as follows:

[0039] 1) Weigh a certain amount of amphiphilic organosilane solution according to the proportion, dissolve it in 100ml of water, then add sodium silicate solution and NaOH and stir to dissolve as silicon source. Sodium metaaluminate was dissolved in 50 ml of water as an aluminum source. The aluminum source solution was added dropwise to the silicon source solution at 40° C., vigorously stirred for 10 minutes, and left to age for 2 hours. Move the silicon-aluminum mixture into a crystallization kettle for crystallization at 99±1°C for 4 hours, and cool naturally. The crystallized product was suction-filtered to obtain molecular sieve crystals, washed three ...

Embodiment 2~18

[0043] The steps of the preparation method of the multi-stage porous 5A molecular sieve spherical adsorbent are the same as in Example 1, except that the molar ratio of the components in the raw materials, amphiphilic organosilane, silicon source and aluminum source, and the type of calcium salt used for exchange are different, as shown in the table 1 and 2 are shown.

[0044] Table 1

[0045]

[0046]

[0047] Table 2

[0048]

[0049]

Embodiment 19

[0051] The 5A adsorbent samples prepared in Examples 1-18 were characterized and analyzed using a Micromeritics ASAP 2020 nitrogen physical adsorption instrument. The pretreatment method of the sample before analysis is as follows: vacuumize the molecular sieve sample at room temperature, and when the vacuum condition is reached, treat it at 130°C for 2h; then treat it at 350°C for 2h. The nitrogen physical adsorption results show that samples 1-20 have a micropore diameter of 0.3-0.5 nm, and all contain mesopore diameter distribution, mesopore average pore diameter, mesopore volume and specific surface area as shown in Table 3.

[0052] table 3

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com