Preparation method of modified illite adsorbent for removing naphthol green B

A technology of illite and adsorbent, which is applied in the field of preparation of modified illite adsorbent, can solve the problems of difficult discharge standards, high alkalinity, complex molecular structure, etc., achieve adsorption equilibrium time quickly, and have mild reaction conditions. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A preparation method for removing a modified illite adsorbent of naphthol green B, comprising the steps:

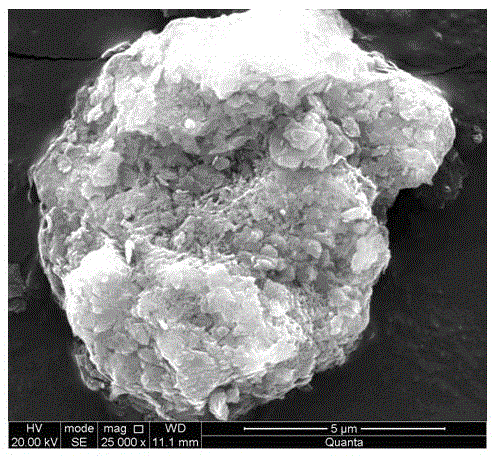

[0017] The illite ore is crushed, sieved, and ground until the particle size is less than 74 μm, and then the illite and cetyltrimethylammonium bromide are mixed according to the weight ratio of 20:1 to prepare a solution, and heated to 80 o C, dropwise add hydrochloric acid with a concentration of 0.1mol / L to adjust the pH to 3~4, then adjust the pH to 75~85 o C Stir at constant temperature and let it stand for 10-12 hours for activation, then dry it to obtain the adsorbent HDTMA-1.

Embodiment 2

[0019] A preparation method for removing a modified illite adsorbent of naphthol green B, comprising the steps:

[0020] The illite ore is crushed, sieved, and ground until the particle size is less than 74 μm, and then the illite and cetyltrimethylammonium bromide are mixed according to the weight ratio of 10:1 to prepare a solution, and heated to 80 o C, dropwise add hydrochloric acid with a concentration of 0.1mol / L to adjust the pH to 3~4, then adjust the pH to 75~85 o C Stir at constant temperature and let it stand for activation for 10-12 hours, then dry it to obtain the adsorbent.

Embodiment 3

[0022] A preparation method of a modified illite adsorbent for removing naphthol green B, comprising the steps of:

[0023] The illite ore is crushed, sieved, and ground until the particle size is less than 74 μm, and then the illite and cetyltrimethylammonium bromide are mixed according to the weight of 30:1 to prepare a solution, and heated to 80 o C, dropwise add hydrochloric acid with a concentration of 0.1mol / L to adjust the pH to 3~4, then adjust the pH to 75~85 o C Stir at constant temperature and let it stand for activation for 10-12 hours, then dry it to obtain the adsorbent.

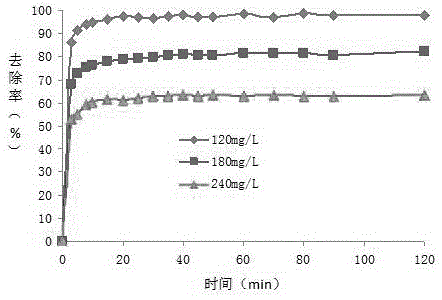

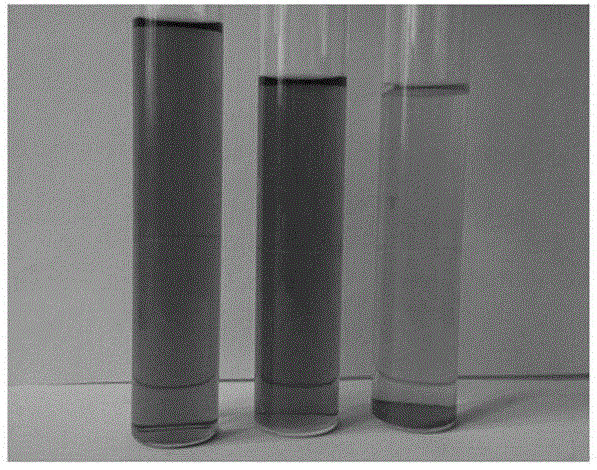

[0024] Take 0.1 g of the adsorbents prepared in three proportions, respectively, and disperse each in 20 ml of 200 mg / L naphthol green B solution, and oscillate and adsorb at 298K for 30 min. The results are shown in Table 1.

[0025] Table 1 Adsorption effect of different mass ratio adsorbents on naphthol green

[0026] Adsorbent ratio 10:1 20:1 30:1 Removal rate (%) 62.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com