Metal organic framework adsorbent with subvalent metal node prepared by steam reduction method as well as preparation method and application of metal organic framework adsorbent

A technology of metal-organic frameworks and metal nodes, applied in organic chemistry, adsorption purification/separation, chemical instruments and methods, etc., can solve problems such as weak adsorption and poor adsorption and separation effects, achieve high adsorption and separation efficiency, improve network Combined ability and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

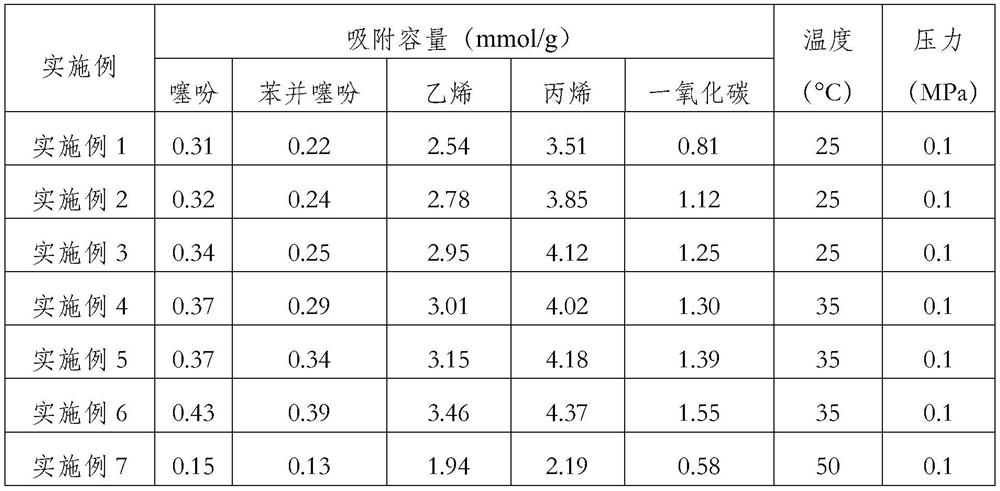

Examples

Embodiment 1

[0024] Weigh 0.1g metal node as Fe 3+ The dry powder of MIL-100 is placed in a glass bottle and placed in isolation from 2mL N,N'-dimethylformamide to ensure that the two do not touch. After sealing, place it in an oven at 250°C for 10 hours. After cooling, you can get Fe 2+ Metal-organic framework adsorbents at metal nodes.

Embodiment 2

[0026] Weigh 0.1g metal node as Fe 3+ The dry powder of MIL-100 is placed in a glass bottle, separated from 2mL formamide to ensure that the two do not touch, sealed and placed in an oven at 250°C for 10h, and after cooling, the Fe-containing 2+ Metal-organic framework adsorbents at metal nodes.

Embodiment 3

[0028] Weigh 0.1g metal node as Fe 3+ The dry powder of MIL-100 is placed in a glass bottle, separated from 2mL of acetamide to ensure that the two are not in contact, sealed and placed in an oven at 250°C for 10 hours, and after cooling, the Fe-containing 2+ Metal-organic framework adsorbents at metal nodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com