Preparation and application of high-stability cuprous modified metal organic framework material

A metal-organic framework, high-stability technology, applied in the refining of hydrocarbon oil, processing of hydrocarbon oil, petroleum industry, etc. Point instability and other problems, to achieve the effect of simple method, improved moisture resistance, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

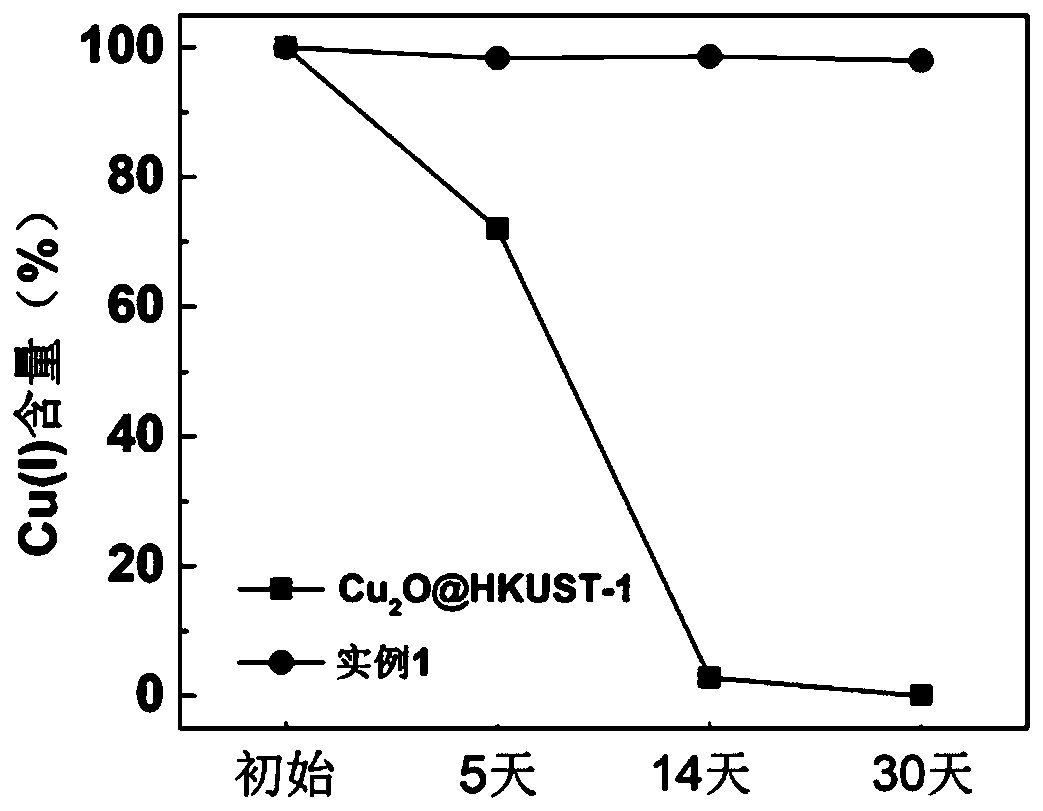

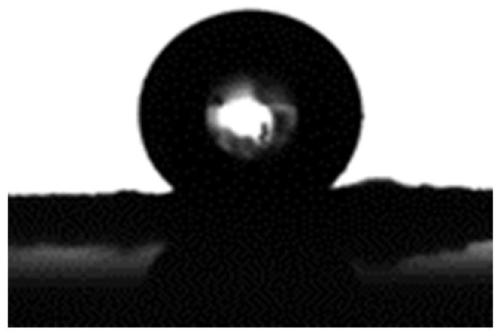

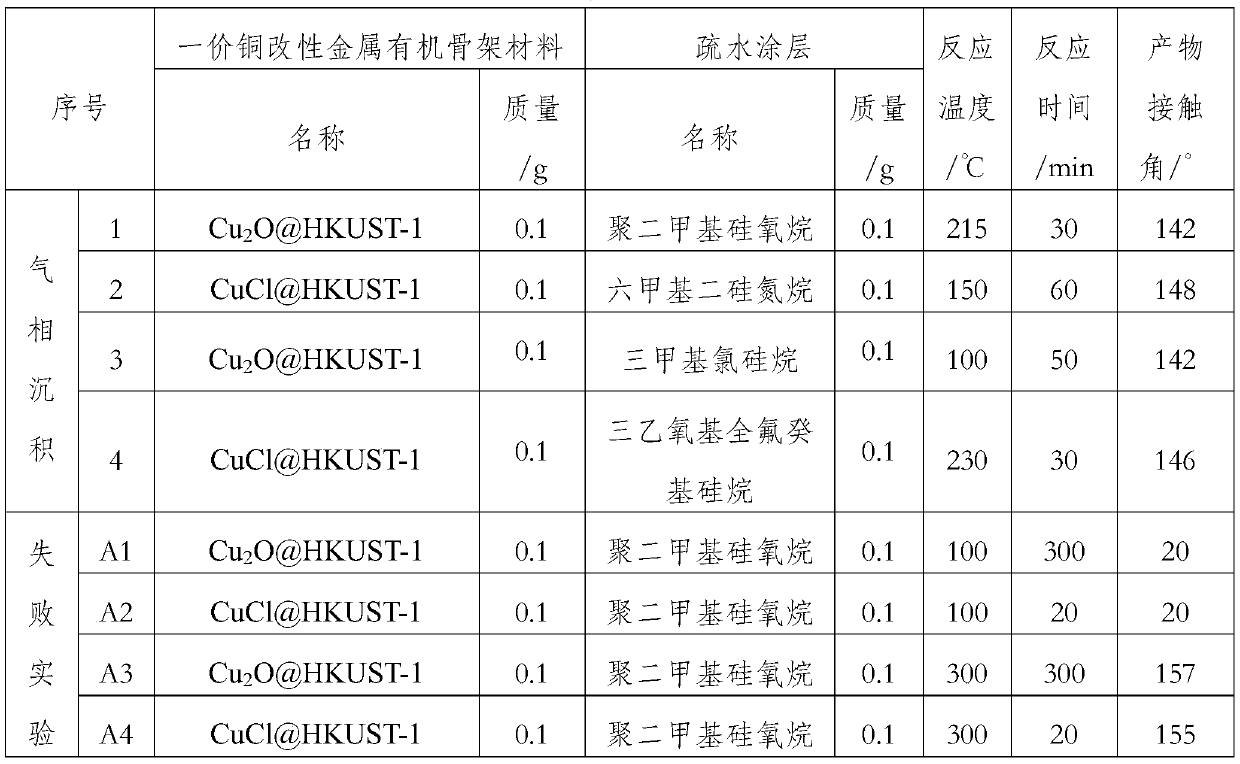

[0029] Weigh 0.1g Cu 2 Spread O@HKUST-1 powder in a glass bottle, put 0.1g of polydimethylsiloxane around it to ensure that the two do not touch, seal it and vacuumize it, put it in 215°C for 30 minutes, and let it cool down to room temperature naturally. A highly stable monovalent copper metal-organic framework material was obtained, and the deposited amount of polydimethylsiloxane was 5.9 wt%. After testing, the contact angle was 142°, and it was hydrophobic.

[0030] In the experiment, guarantee Cu 2 O@HKUST-1 powder is not in contact with polydimethylsiloxane, and under high temperature and vacuum conditions, polydimethylsiloxane is vapor-deposited on the surface of the metal-organic framework to form a uniform hydrophobic coating; if both After contact, polydimethylsiloxane does not become vapor-phase deposited on the surface of the metal-organic framework material, but if it is physically mixed, the amount of polydimethylsiloxane will increase, which will cause clogging...

Embodiment 2

[0036] According to Table 2, the monovalent copper-modified metal-organic framework material was dispersed in a solvent to form a suspension, and then the hydrophobic coating was also dispersed in the solvent. After the two are mixed, they are spray-dried in an inert gas, and the collected samples are washed with a solvent and dried in vacuum at 120°C to obtain a highly stable monovalent copper-modified MOF adsorbent.

[0037] Table 2

[0038]

[0039] The mass concentration ratio of the monovalent copper-modified metal-organic framework material to the hydrophobic coating determines the mass content of the hydrophobic coating coated on the surface of the material. When the mass concentration ratio is too large, the adsorbent is still hydrophilic. If the mass concentration ratio of the material is too small, an excessive amount of hydrophobic coating will be introduced to block the pores, which will seriously affect the adsorption performance. As can be seen from the exper...

Embodiment 3

[0041] According to Table 3, weigh the monovalent copper-modified metal-organic framework material, monomer and initiator, add a solvent, seal the reaction at a certain temperature, and naturally cool to room temperature to prepare a highly stable monovalent copper-modified metal-organic framework material Adsorbent.

[0042] table 3

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com