Temperature-pressure synergy adsorption separation purification method for gases

A technology of gas adsorption and purification method, which is applied in the field of temperature-pressure collaborative gas adsorption separation and purification, coal mine drainage of low-concentration gas and ventilation gas adsorption, separation and purification, which can solve problems such as difficult and effective separation, and achieve high energy consumption, Improved adsorption and separation efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

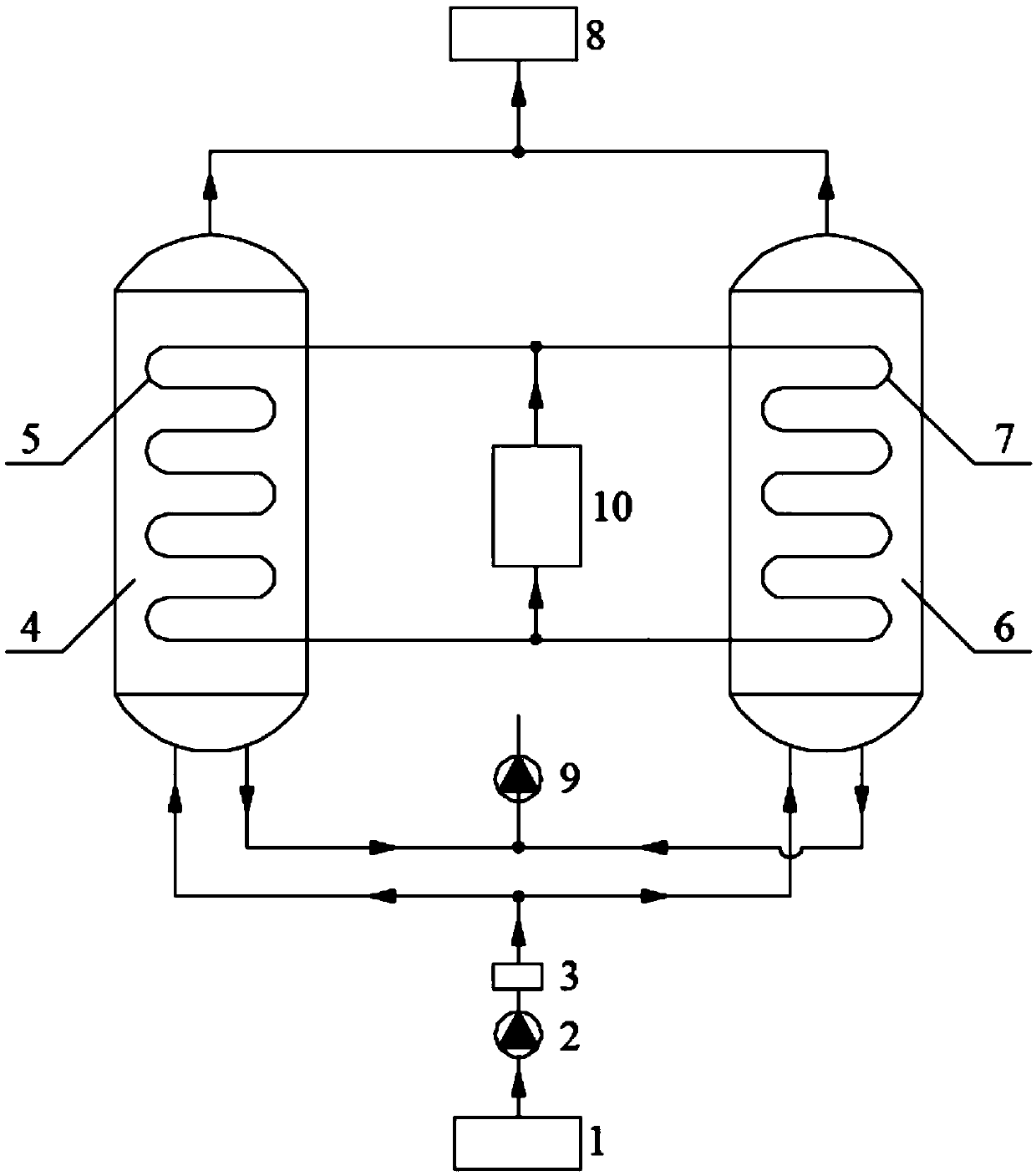

[0026] In this embodiment, the gas to be separated is methane / nitrogen mixed feed gas (methane concentration is lower than 30%). use as figure 1 The temperature-swing-pressure-swing adsorption system shown, the system includes an air intake unit 1, an exhaust unit 8, and two parallel adsorption towers I4 and adsorption tower II6. The interior of the adsorption tower I4 is provided with a heat exchanger I5, and the interior of the adsorption tower II6 is provided with There is a heat exchanger II7, and both the heat exchanger I5 and the heat exchanger II7 are serpentine tube heat exchangers. Adsorption tower I4 is filled with activated carbon adsorbent, and adsorption tower II6 is filled with molecular sieve adsorbent.

[0027] Purification steps are as follows:

[0028] (1) After the mixed raw material gas is pressurized by the air compressor 2 through the air inlet unit 1, it first enters the cold dryer 3 to remove moisture, and then enters the adsorption tower I4, and the ...

Embodiment 2

[0033] In this embodiment, the gas to be separated is methane / nitrogen mixed feed gas (methane concentration is lower than 30%). use as figure 1The temperature-swing-pressure-swing adsorption system shown, the system includes an air intake unit 1, an exhaust unit 8, and two parallel adsorption towers I4 and adsorption tower II6. The interior of the adsorption tower I4 is provided with a heat exchanger I5, and the interior of the adsorption tower II6 is provided with There is a heat exchanger II7, and both the heat exchanger I5 and the heat exchanger II7 are serpentine tube heat exchangers. Adsorption tower I4 is filled with molecular sieve adsorbent, and adsorption tower II6 is filled with metal organic framework material adsorbent.

[0034] Purification steps are as follows:

[0035] (1) After the mixed raw material gas is pressurized by the air compressor 2 through the air inlet unit 1, it first enters the cold dryer 3 to remove moisture, and then enters the adsorption tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com