A highly dispersed metal or metal oxide doped adsorbent, preparation method and application thereof

A technology of oxides and adsorbents, applied in carbon monoxide, chemical instruments and methods, adsorption purification/separation, etc., can solve the problems of inability to maximize the effect of active sites, poor adsorption and separation effects, and difficult access to active sites, etc., to achieve The method is simple, the selectivity is high, and the effect of improving the dispersion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

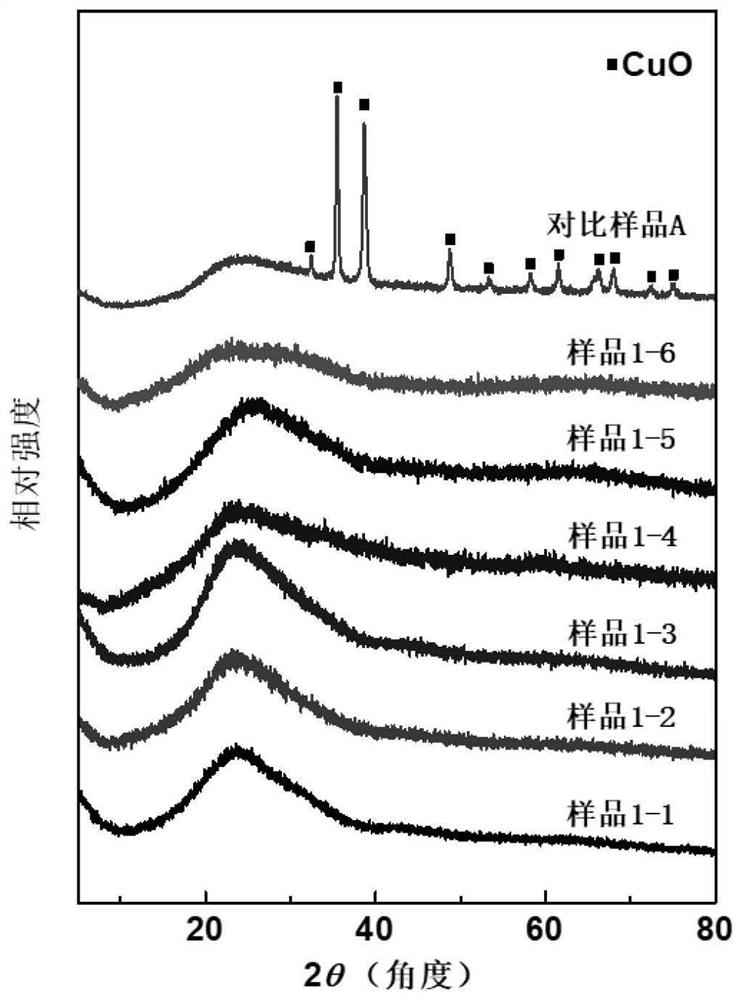

[0042]According to Table 1, weigh 0.2g carrier and disperse it in 10mL methanol, add metal node precursor and organic ligand, stir at 70°C for 10h, wash and dry, place in a tube furnace and roast at 450°C for 5h to obtain high Dispersed metal or metal oxide doped adsorbent samples 1-1 to 1-6.

Embodiment 2

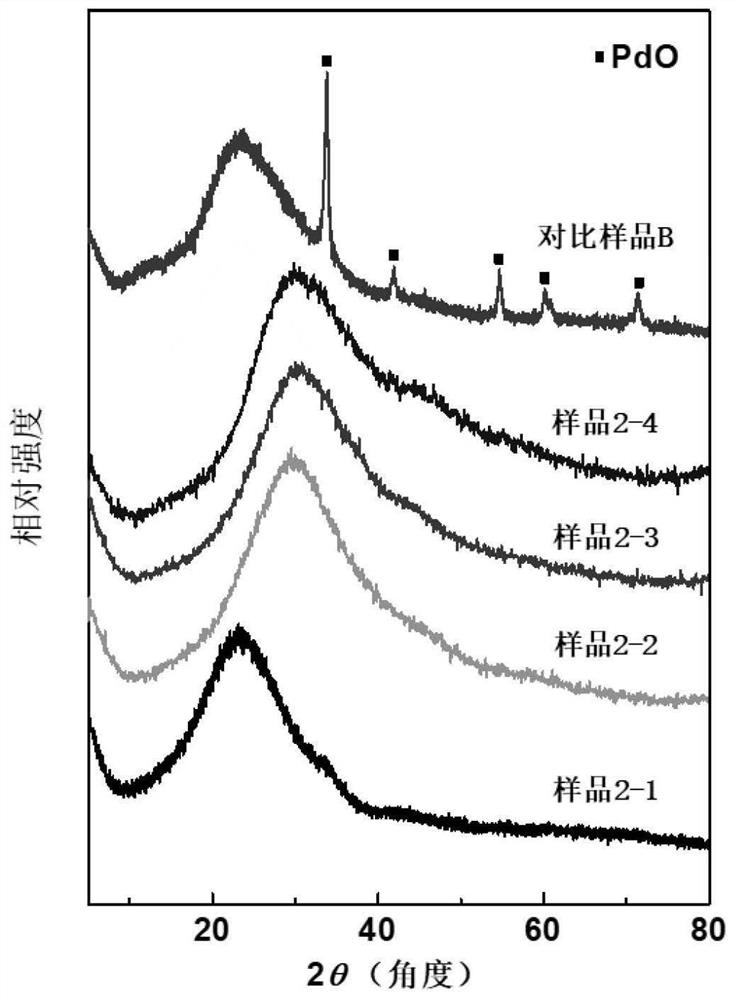

[0048] According to Table 2, weigh 0.2g carrier and disperse it in 10mL methanol, add metal node precursor and organic ligand, stir at 70°C for 10h, wash and dry, place in a tube furnace and roast at 450°C for 5h to obtain high Dispersed metal or metal oxide doped adsorbent samples 2-1 to 2-4.

[0049] Comparative example: weigh 0.2g SiO 2 Disperse in 10mL methanol, add 0.023g palladium nitrate dihydrate and 0.026g 4,4-bipyridine, stir at 70°C for 10h, wash and dry, place in a tube furnace and roast at 450°C for 5h to prepare silica Comparative sample B as carrier.

[0050] Table 2

[0051]

[0052] Carry out XRD characterization on samples 2-1~2-4 and comparative sample B, the results are as follows figure 2 shown. From figure 2 It can be seen in the comparison sample B that although SiO 2 Palladium-doped adsorbents, but metal diffraction peaks appeared in the XRD characterization, while samples 2-1 to 2-4 did not appear metal diffraction peaks, which indicated tha...

Embodiment 3

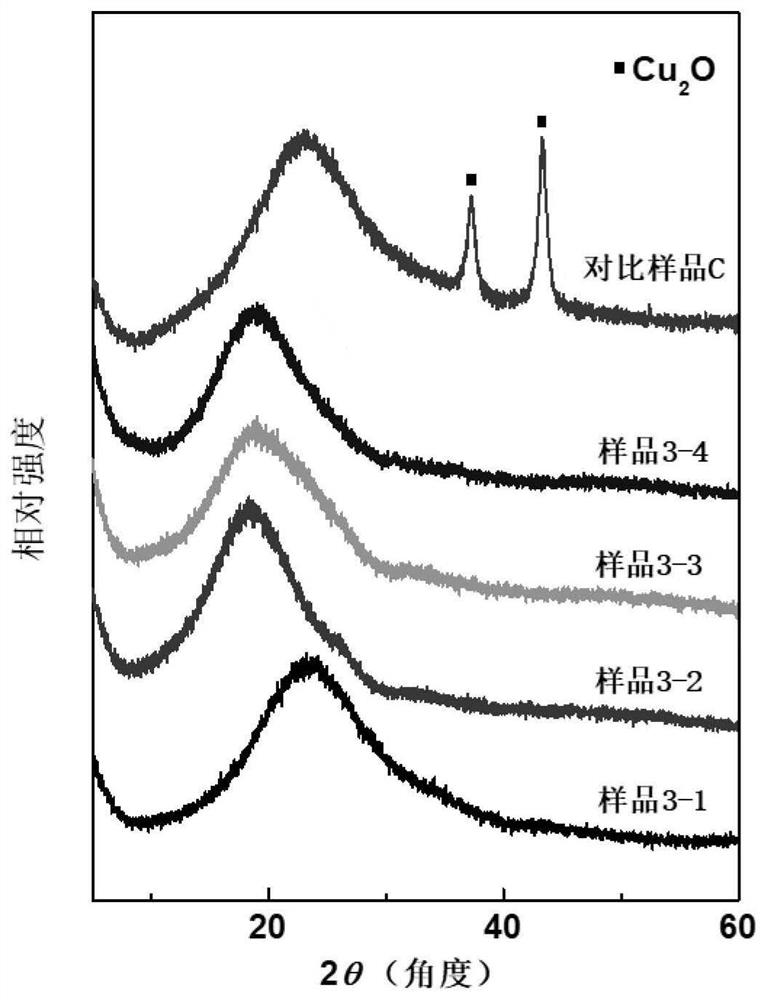

[0054] According to Table 3, weigh 0.2g carrier and disperse it in 10mL methanol, add metal node precursor and organic ligand, stir at 70°C for 10h, add 0.2g reducing agent and continue stirring for 1h, wash and dry to obtain highly dispersed metal or Metal oxide doped adsorbent samples 3-1 to 3-4.

[0055] Comparative example: weigh 0.2g SiO 2 Disperse in 10mL methanol, add 0.028g copper nitrate hexahydrate and 0.043g 5-hydroxyisophthalic acid, stir at 70°C for 10h, then add 0.2g reducing agent sodium sulfite and continue stirring for 1h, wash and dry to obtain silica Comparative sample C as carrier.

[0056] table 3

[0057]

[0058]

[0059] Samples 3-1 to 3-4 and comparative sample C were characterized by XRD, the results are as follows image 3 shown. From image 3 It can be seen in the comparison sample C that although SiO 2 Copper-doped adsorbents, but metal diffraction peaks appeared in the XRD characterization, while samples 3-1 to 3-4 did not appear metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com