High-performance adsorption film based on ZIFs material

A high-performance, thin-film technology, applied in the fields of adsorption water/sewage treatment, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of poor operability and processability, poor dispersion of hydrophobic ZIFs powder, poor adsorption performance, etc. Achieve high removal rate, improve adsorption and separation efficiency, and simple membrane production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add an appropriate amount of cobalt acetate to 15ml of ethanol, mix and heat in a water bath at 60°C for 30 minutes, then add ethanolamine solution at a ratio of cobalt acetate to ethanolamine molar volume ratio of 1.8mol / L, and then continue heating the reaction system in a water bath at 60°C for 0.5h to obtain a cobalt-based sol ; use a smooth glass rod to coat a certain thickness of cobalt-based sol on the surface of the polyvinylidene fluoride (PVDF) film, and heat-treat the PVDF film with the sol coating at 150 ° C for 30 min to evaporate the solvent and obtain a continuous cobalt-based gel. Adhesive layer; at 150°C, place the PVDF film with cobalt-based sol layer in sufficient 2-methylimidazole gas phase monomer to grow ZIF-67 material by vapor phase growth method; after natural cooling, the ZIF-67 film is obtained, and the The film was washed with methanol several times and dried at room temperature to obtain ZIF-67 adsorption film.

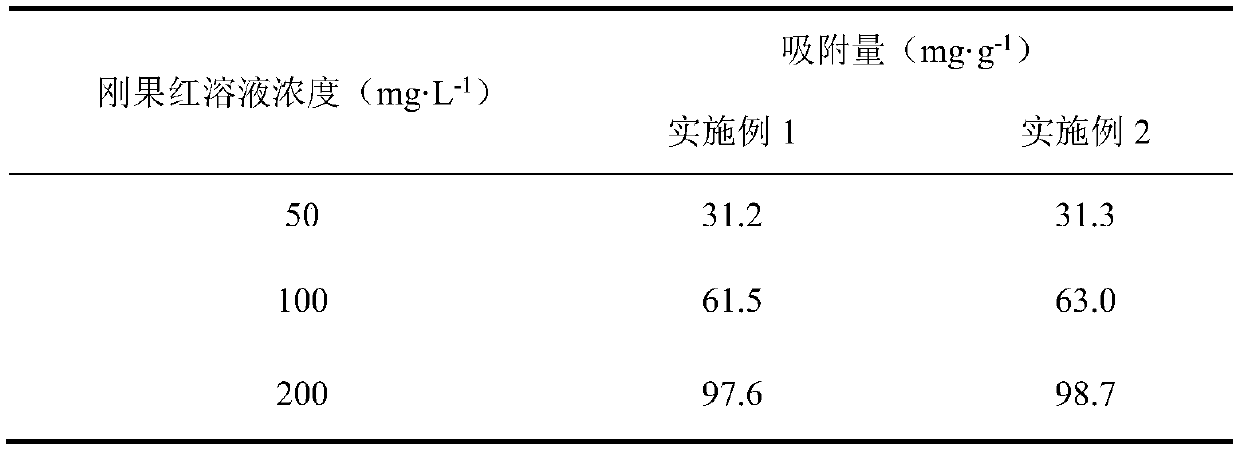

[0014] ZIF-67 adsorption fil...

Embodiment 2

[0018] Add an appropriate amount of zinc acetate to 15ml of ethanol, mix and heat in a water bath at 60°C for 30 minutes, then add ethanolamine solution at a ratio of 2.0mol / L by molar volume ratio of zinc acetate to ethanolamine, and then continue heating the reaction system in a water bath at 60°C for 0.5h to obtain a zinc-based sol ; Use a smooth glass rod to coat a certain thickness of zinc-based sol on the surface of polyvinylidene fluoride (PVDF) film, and heat-treat the PVDF film with sol coating at 150 ° C for 30 min to evaporate the solvent and obtain a continuous zinc-based gel. Adhesive layer; at 150°C, place the PVDF film with zinc-based sol layer in sufficient 2-methylimidazole gas phase monomer to grow ZIF-8 material by vapor phase growth method; after natural cooling, ZIF-8 film is obtained, and the The film was washed with methanol several times and dried at room temperature to obtain ZIF-8 adsorption film. The adsorption test of the ZIF-8 adsorption film is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com