An automatic column-loading continuous operation series macroporous resin adsorption separation device

A macroporous resin, adsorption separation technology, applied in the direction of solid adsorbent liquid separation, separation methods, chemical instruments and methods, etc. The effect of enhancing consistency and improving adsorption separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

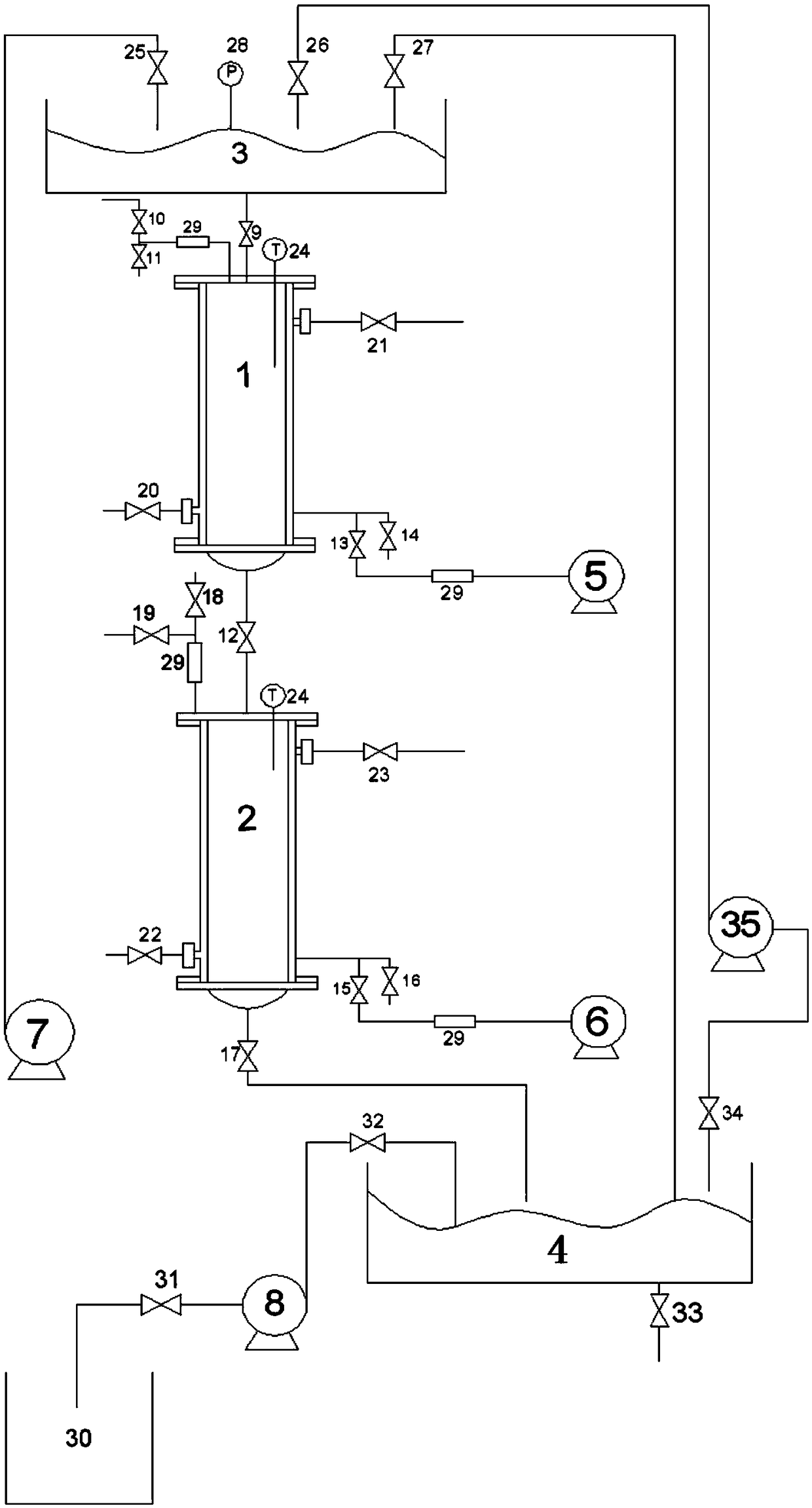

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The automatic column loading continuous operation series macroporous resin adsorption and separation device of the present invention mainly consists of an adsorption column 1, an analysis column 2, a sample liquid circulation pump 5, an eluent circulation pump 6, a regeneration liquid circulation pump 8, a vacuum pump 7, a temperature It consists of a sensor 24, a pressure gauge 28, a regeneration tank 4, a high-level quantitative tank 3, a regeneration liquid storage tank 30, pipelines, and valves. The adsorption column 1 is connected in series with the analytical column 2, the upper part of the adsorption column 1 has a resin inlet 9, the first sample liquid inlet and outlet 13, 10, and the lower part has a resin outlet 12, a second sample liquid inlet and outlet 11, 14; the upper part of the analytical column 2 There are resin inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com