Method for manufacturing superfine denier modified terylene torque-less false twist textured yarn and special thread guide

A technology of false twist textured yarn and manufacturing method, which is applied in the manufacture of ultra-fine denier modified polyester non-torque false twist textured yarn, and the field of double-filament free-rotating yarn guide, which can solve the problems of poor dyeability, difficult production, Poor air permeability and other problems, to achieve the effect of improving quality, simple structure and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

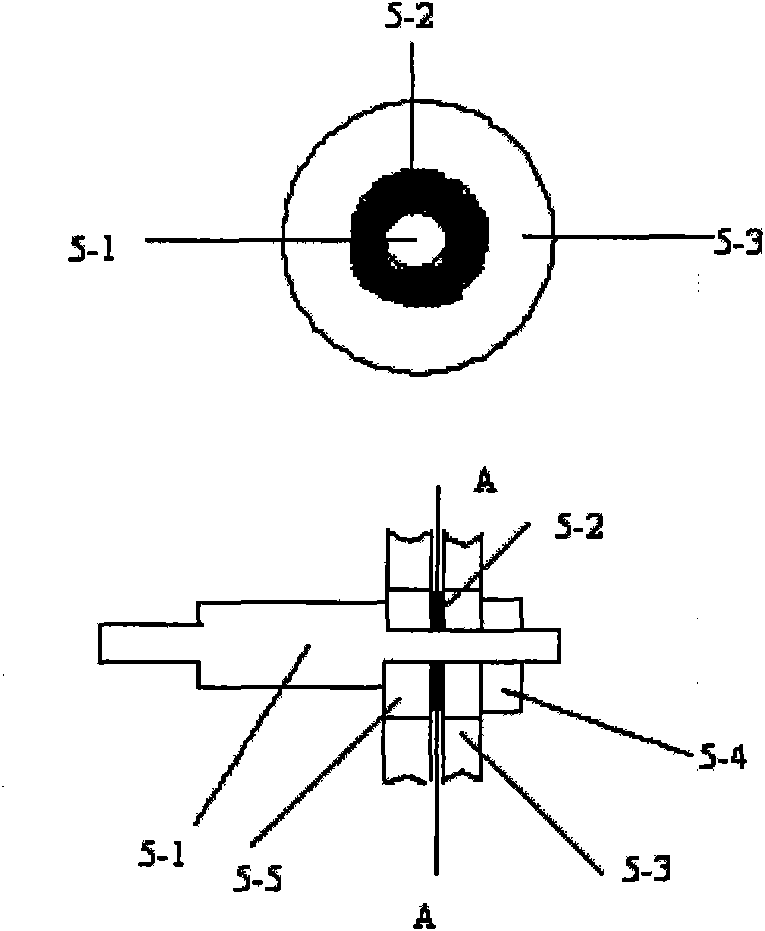

[0021] See figure 1 In this example, the double-filament free-rotating wire guide, one end of the yarn guide shaft 5-1 is a stepped shaft, and its details are covered with two concave wire rollers 5-3 in the middle, and the wire rollers are embedded with bearings 5-5 , the bearing inner sleeve is set on the wire guide shaft 5-1; there is an O-shaped washer 5-2 between the two wire rollers, and the diameter of the O-type washer is slightly smaller than the diameter of the bearing inner sleeve; the other end of the wire guide shaft has a nut 5- 4. Limit the two silk rollers 5-3.

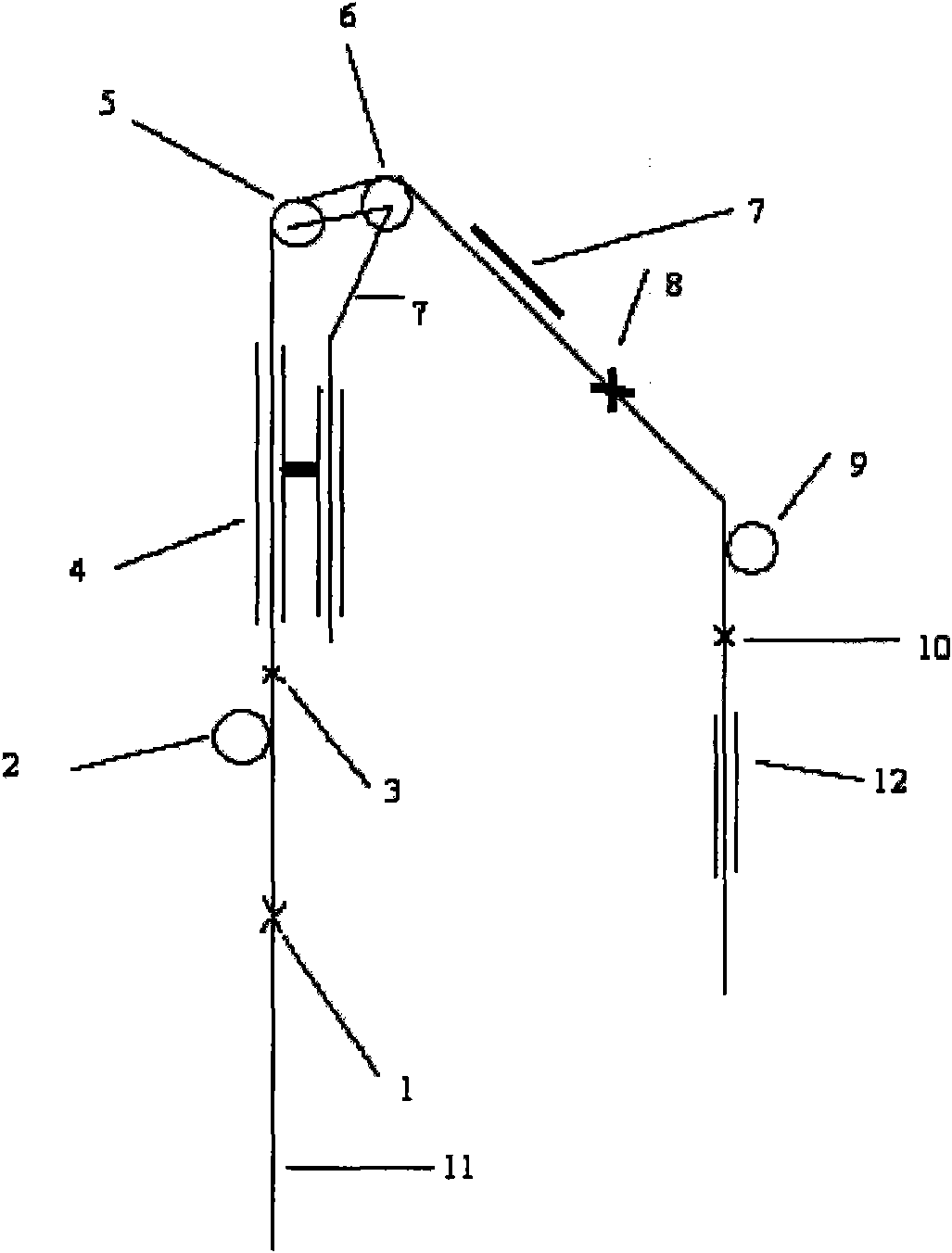

[0022] See figure 2 , a method for manufacturing superfine denier cationic modified polyester non-torque false twisted textured yarn, 75D / 192F superfine denier cationic modified polyester POY two strands 11 respectively enter a roller front yarn guide 1 through their respective silk paths , Then enter a roller 2, pass through a hot box inlet yarn guide 3, enter a hot box 4, and in a hot box, the fil...

Embodiment 2

[0024] Another method for manufacturing superfine denier conventional polyester non-torque false twist textured yarn of the present invention

[0025] A method for manufacturing ultra-fine denier cationic modified polyester torque-free false-twisted textured yarn. 50D / 144F ultra-fine denier conventional polyester POY two strands enter the first roller through their respective silk paths, and then enter the first roller. 2. Enter a hot box 4 through a hot box inlet wire guide 3, and the filaments in a hot box are heated in contact with a hot box 4; And turn to the double-filament free-rotating yarn guide 6, pass through the cooling plate 7, enter the false twister 8 to perform false twist deformation in different twist directions of S and Z, enter the second roller 9, and then enter the second heat through the network nozzle 10 for plying After the case 12 is heat-set, a 100D / 288F superfine denier conventional polyester non-torque false twist textured yarn is obtained. It is p...

Embodiment 3

[0027] Another method for manufacturing superfine denier cationic modified polyester non-torque false twist textured yarn of the present invention

[0028] A method for manufacturing superfine denier modified polyester torque-free polyester false-twist textured yarn 75D / 144F superfine denier flame-retardant modified polyester POY two strands respectively enter the yarn guide 1 before a roller through their respective silk paths, and then Enter a roller 2, enter a hot box 4 through a hot box inlet yarn guide 3, and heat the filament in a hot box without contact with a hot box 4. The vertical distance is 2mm, and then through a hot box outlet on the push-pull rod, the double-filament free-rotating yarn guide 5 and the turning double-filament free-rotating yarn guide 6 pass through the cooling plate 7, and directly enter the false twister 8 for S and Z different twists respectively. After false-twisting deformation in the same direction, it enters the second roller 9, and then en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com