Inductor wire twisting mechanism and device

A technology of twisting wire mechanism and inductance, which is applied in coil manufacturing and other directions, and can solve problems such as inconsistent looseness, high labor intensity, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

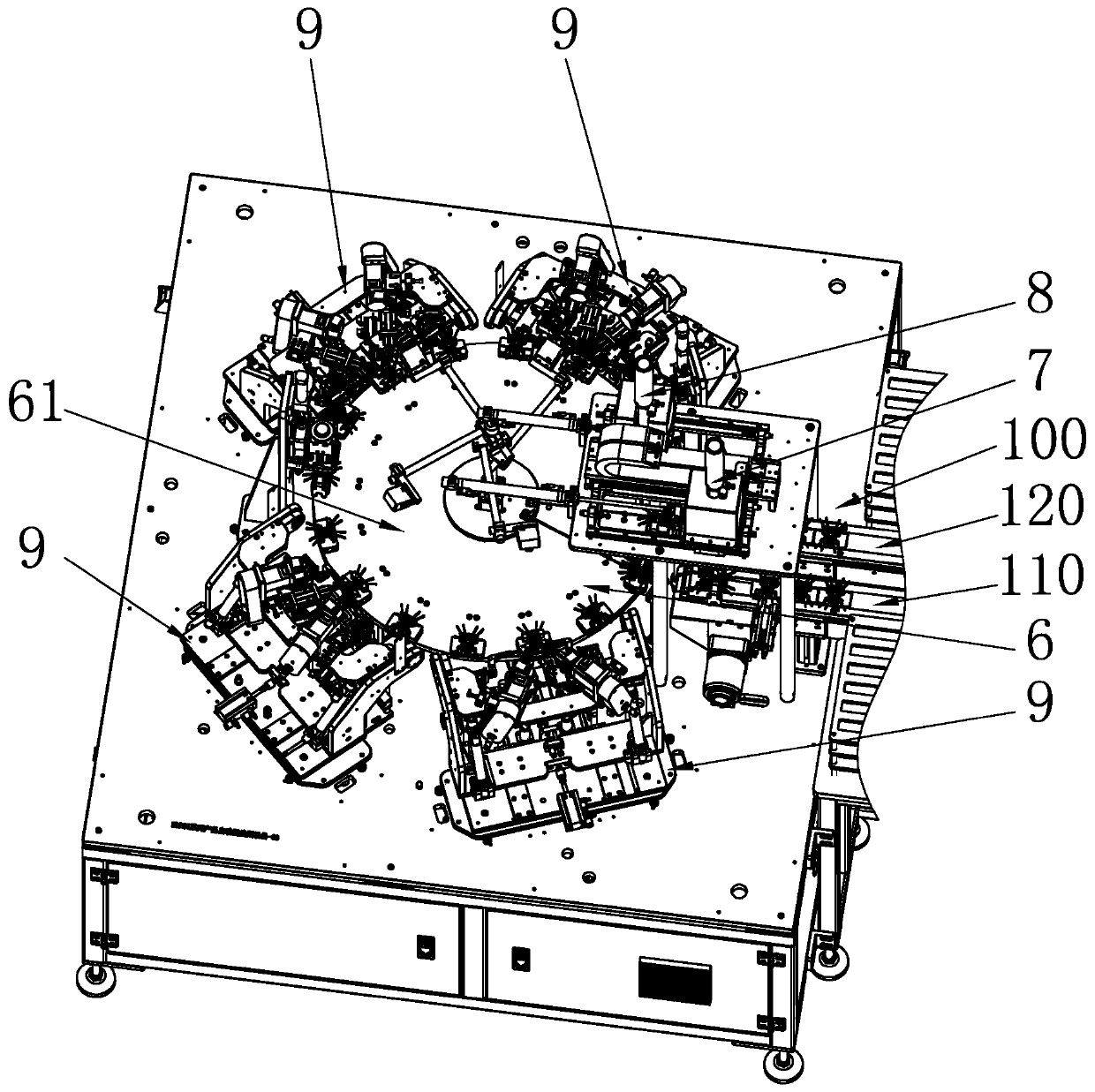

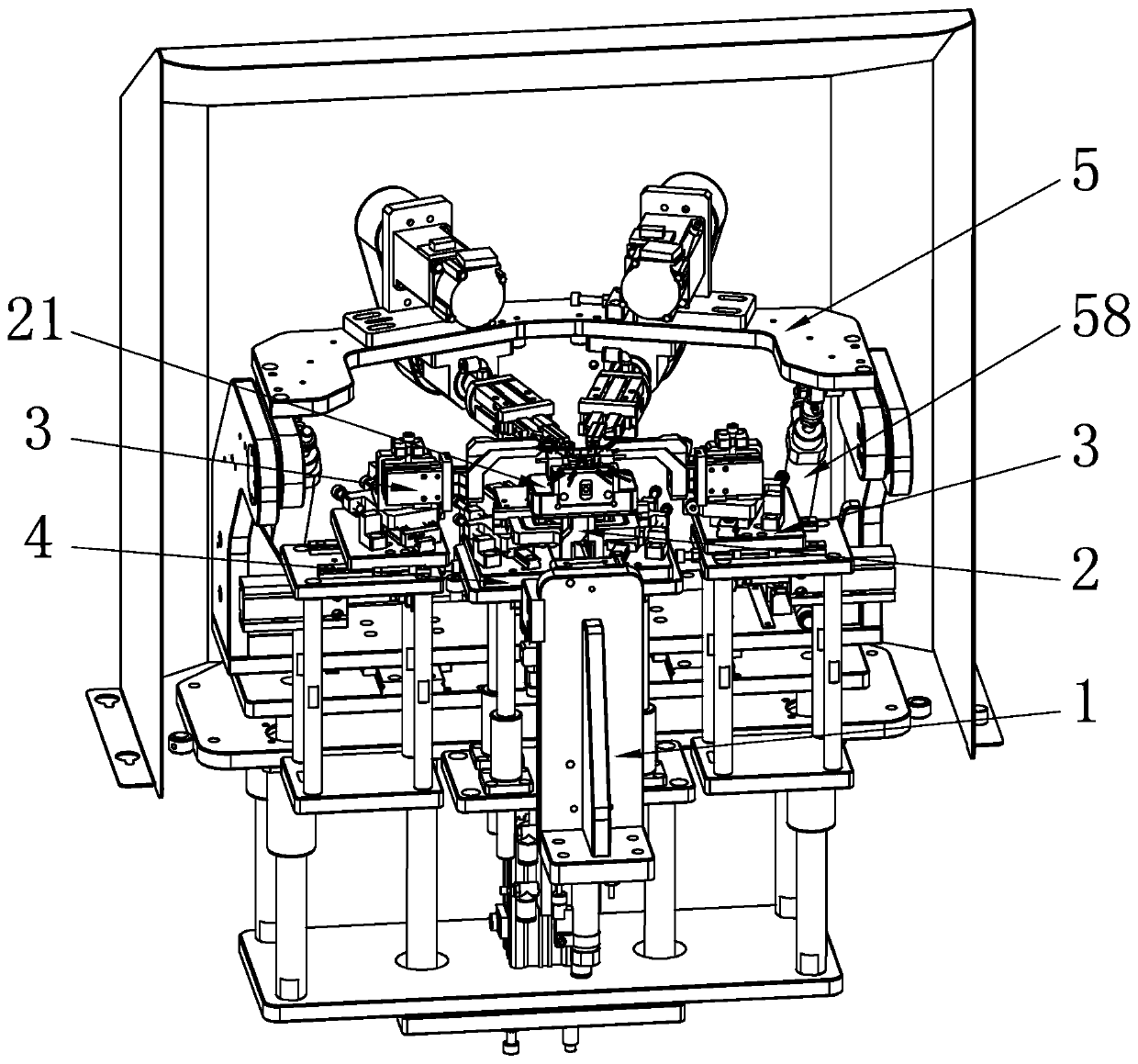

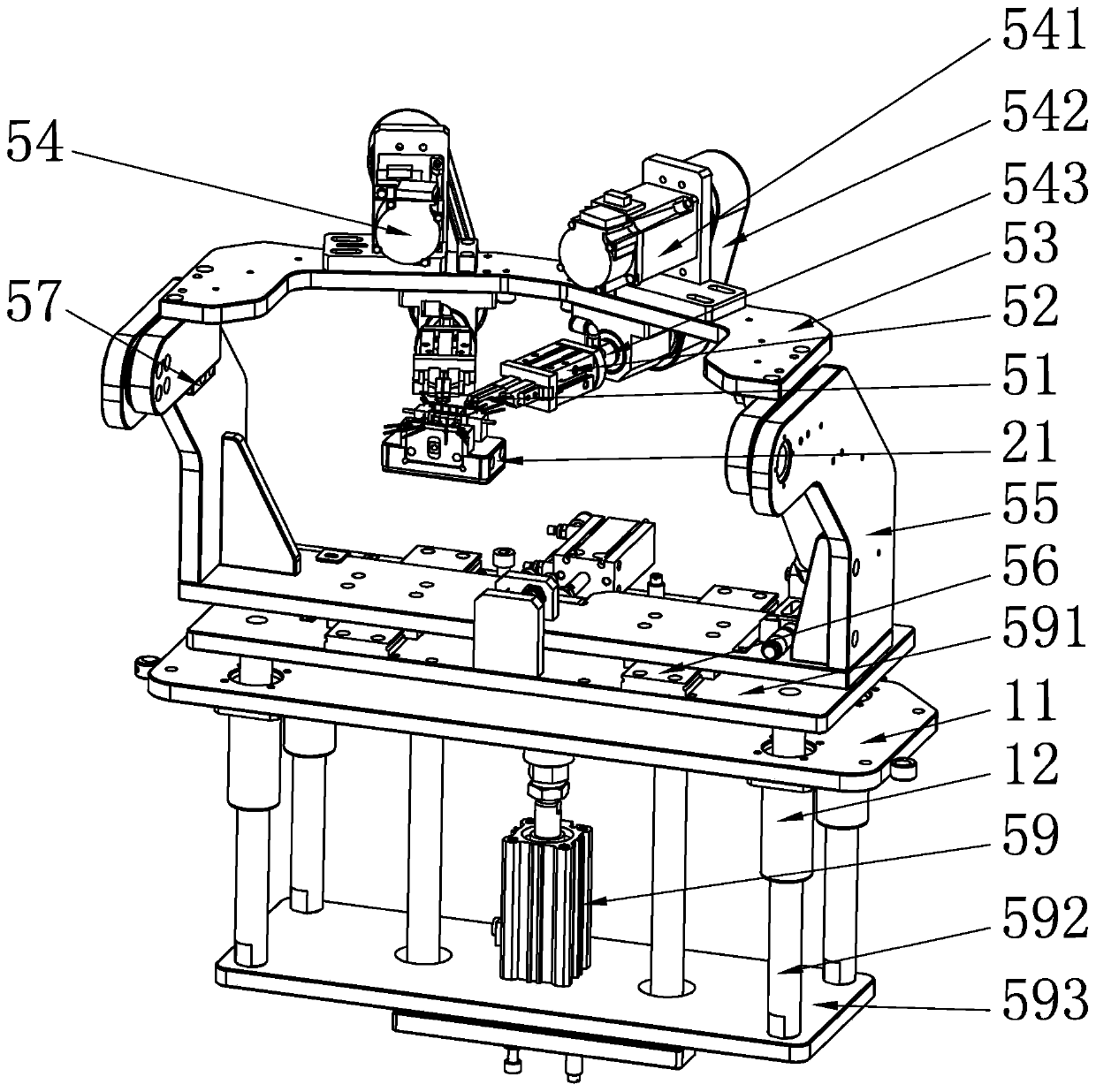

[0033] see figure 2 , Image 6 , Figure 10 with Figure 11 , the invention discloses an inductance twisting mechanism, comprising a frame 1 and a positioning assembly 2 arranged at the front end of the frame 1, the positioning assembly 2 can position a jig 21, and the positioning assembly 2 includes a The first lifting assembly 26 and the fourth slide rail 22 vertically arranged at the front end of the frame 1, the fourth slide rail 22 is correspondingly provided with a fourth slide block 23, and the first lift assembly 26 is located on the fourth slide block 23 Below, the output end of the first lifting assembly 26 is connected with the fourth slide block 23, and the fourth pneumatic clamp finger 24 is vertically installed on the fourth slide block 23, and the output end of the fourth pneumatic clamp finger 24 faces above, and the output end of the fourth pneumatic gripper finger 24 is provided with a positioning jaw 25, and the positioning jaw 25 includes two fourth cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com