Vortex tube for spinning machine

A vortex tube and spinning machine technology, applied in the field of vortex tube, can solve the problems of high air consumption rate and power consumption, affecting the spinning speed, and the gap cannot be too large, so as to save energy consumption, improve spinning quality and Efficiency, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

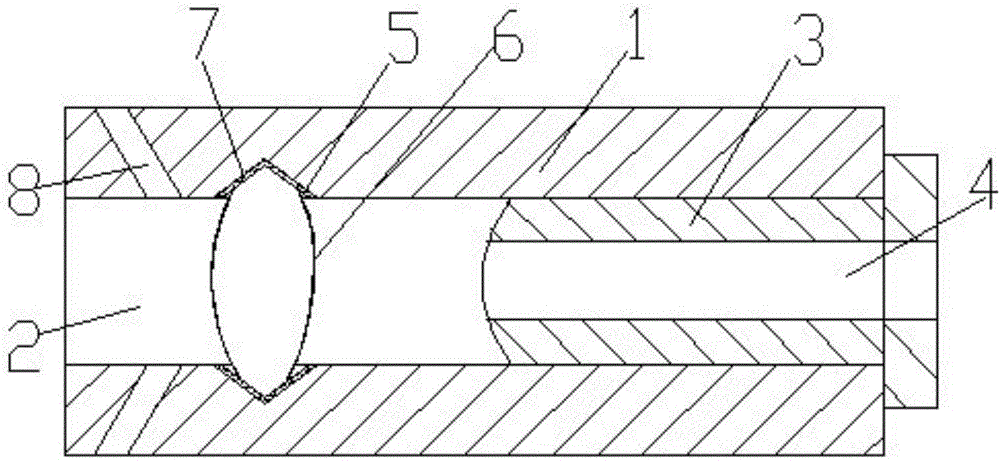

[0011] The vortex tube for spinning machine of the present invention comprises a tube body 1 provided with a hollow cavity 2, one end of the tube body is provided with a plug 3; The yarn guide hole 5, the hollow inner cavity wall is provided with a V-shaped groove structure 5; the V-shaped groove structure 5 is provided with a fiber ring 6; on the V-shaped groove structure 5 and the fiber ring 6 is provided with flannelette tissue 7 at the junction; and an inclined air supply hole 8 is provided on the wall of the hollow inner cavity near the end opposite to the end where the plug 3 is provided. The scheme of the present invention has an inclined air supply hole 8 on the hollow inner cavity wall of the pipe body 1, which can increase the effective air flow in the pipe body, improve the bearing capacity of the fiber ring, increase the rotational speed of the fiber ring, thereby improving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com