Quadruple-twisting machine

A twister and twister technology, which is applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of multi-tasking, high energy consumption and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

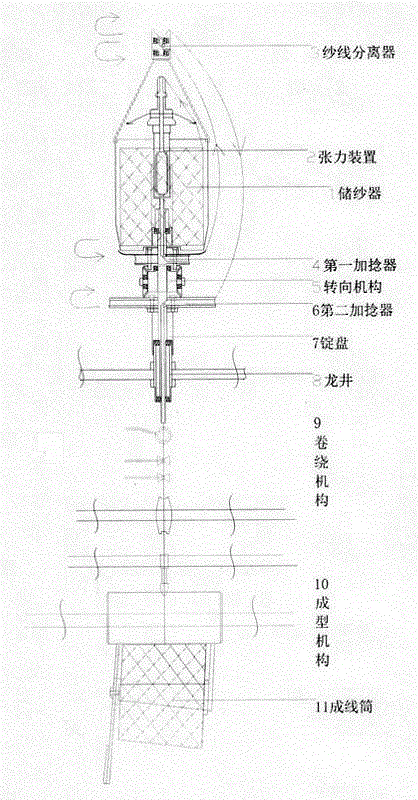

[0007] Structurally, such as figure 1 As shown, 11 forming cylinder, 10 forming mechanism, 9 winding mechanism and 8 Longjing are fixed on the two-for-one twister frame from bottom to top, 7 spindle discs are fixed on 8 Longjing through the spindle, and 6 the second twister is fixed on the ingot On the disk, the 5 steering mechanism is in contact with the 6 second twister and the 4 first twister through gears (or other means), the lower end of the 4 first twister is connected with the rotating shaft by a bearing, and the 1 In the magnetic disk, the magnetic disk is placed on the first twister, the 2 tension device is located in the middle area above the 1 yarn storage device, and the 3 yarn separator is fixed on the upper edge of the 1 yarn storage device by its lower end bracket.

[0008] In terms of power, the engine transmits power to the 7 spindles through the transmission mechanism such as the dragon belt, and the 6 second twister is connected to the 7 spindles to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com