Spinning method for high-count high-quality embedded compact spun yarn

A high-quality, embedded technology, applied in the field of textile processing, can solve the problems of adverse effects and increases in physical indicators such as yarn dryness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

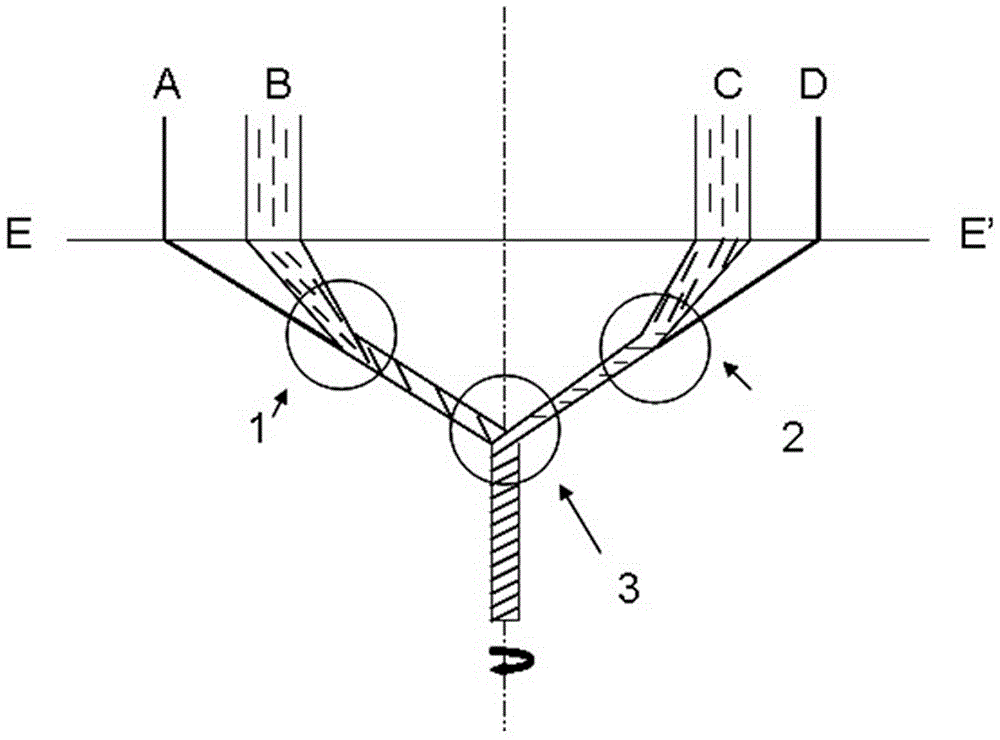

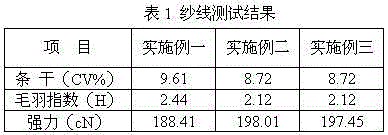

[0012] Cotton roving and nylon filament yarn are selected as spinning raw materials, raw materials A and D are nylon filament yarn, B and C are cotton roving, and the air negative pressure applied is 0.15Mpa. The test results of the yarn obtained after spinning on the spinning frame are shown in Table 1.

Embodiment 2

[0014] Cotton roving and nylon filament yarn are selected as spinning raw materials, raw materials A and D are nylon filament yarn, B and C are cotton roving, and the air negative pressure applied is 0.20Mpa. The test results of the yarn obtained after spinning on the spinning frame are shown in Table 1.

Embodiment 3

[0016] Cotton roving and nylon filament yarn are selected as spinning raw materials, raw materials A and D are nylon filament yarn, B and C are cotton roving, and the air negative pressure applied is 0.25Mpa. The test results of the yarn obtained after spinning on the spinning frame are shown in Table 1.

[0017]

[0018] Through the statistical comparison of the three implementations, it is found that under the condition of negative air pressure of 0.20Mpa, the standard deviation of evenness (CV%), hairiness index (H) and strength index of the obtained product reach relatively ideal indexes.

[0019] Different from conventional methods, the invention has obvious effects on fibers with small initial modulus and fibers with large initial modulus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com