Hollow spindle twisting machine

A spindle and hollow technology, which is applied in the field of hollow spindle twisting machines, can solve the problems of inability to meet the high quality of textiles, multiple patterns, high labor intensity of workers, multiple processes, etc., achieves simple structure, improves twisting efficiency, and increases the number of updated machines. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

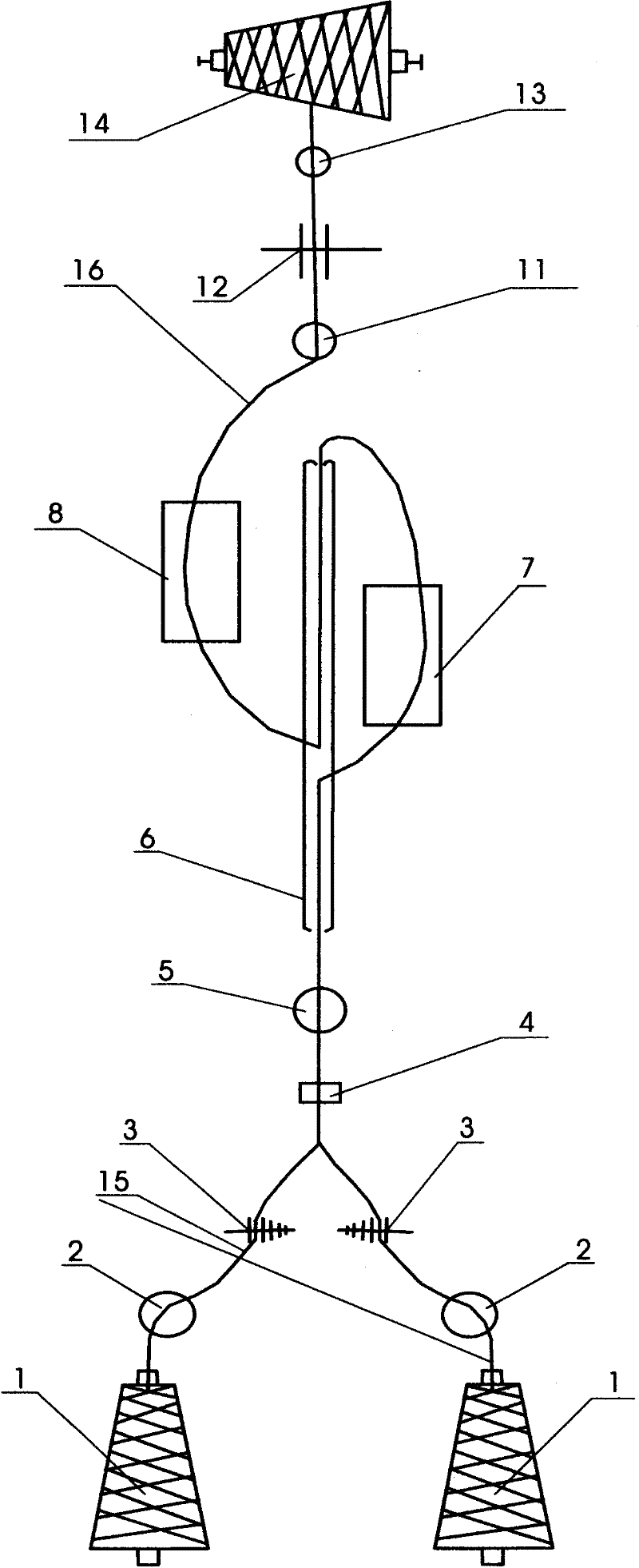

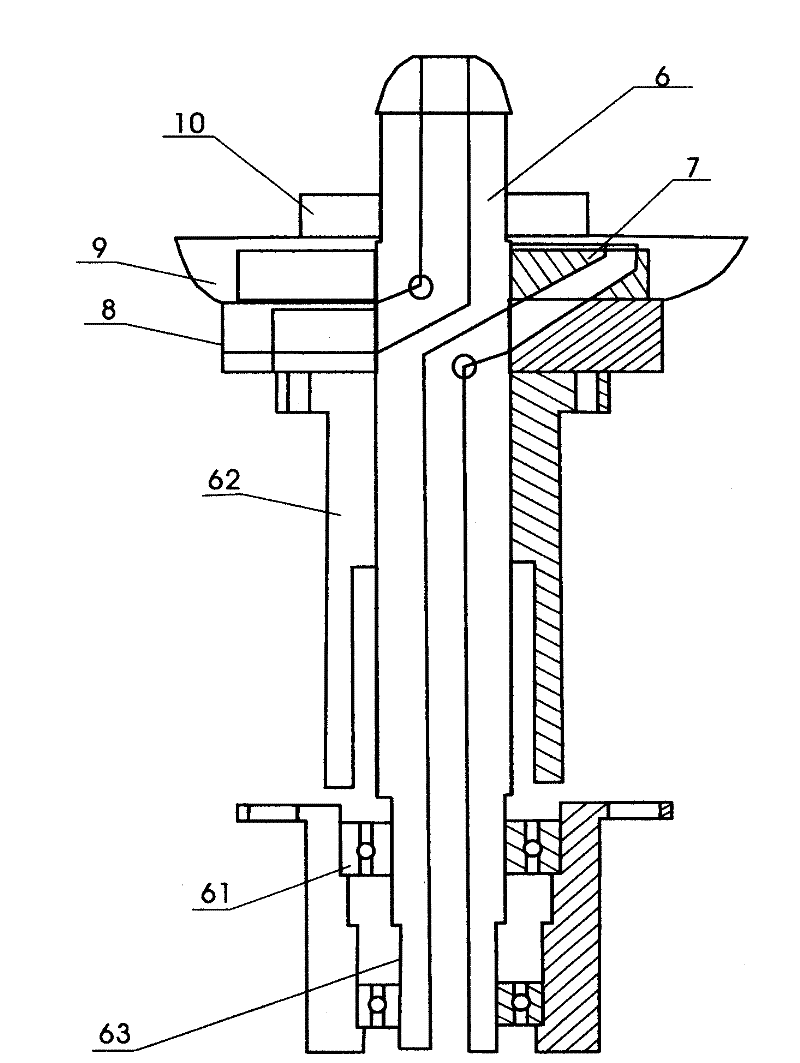

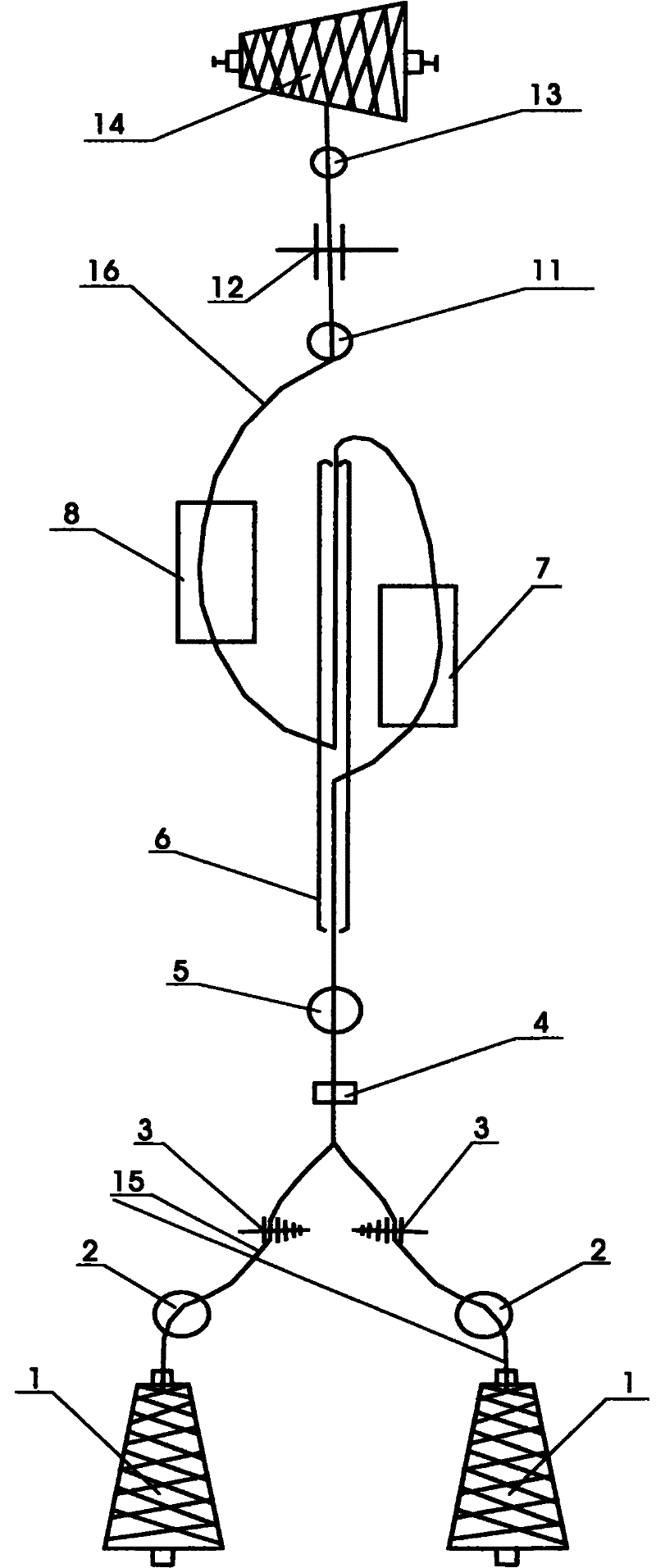

[0021] Figure 1 to Figure 2 As shown in the figure, the present invention is mainly composed of single-thread bobbin holder 1, primary yarn guide 2, tension regulator 3, yarn break automatic stop device 4, secondary yarn guide 5, hollow spindle 6, primary twister 7, secondary Two-for-one twister 8, inner balloon controller 9, outer balloon controller 10, tertiary yarn guide 11, tension twist device 12, anti-folding thread guide 13 and strand winding device 14. It is characterized in that: two groups of single-thread bobbin holders 1 are arranged on the frame below the frame, two groups of primary yarn guides 2 are correspondingly arranged on the frame above the single-thread bobbin holder 1, and two sets of tension regulators 3 are arranged correspondingly on the frame On the frame above the yarn guide 2, the yarn break automatic stop device 4 is set on the frame above the tension regulator 3, and the secondary yarn guide 5 is set on the frame above the thread break automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com