Carpet yarn twisting machine

A technology for twisting machine and carpet yarn, which is applied in spinning machine, continuous winding spinning machine, textile and paper making, etc., can solve the problems of complex structure of tension regulator and torque effect, so as to ensure uniform winding. degree, improve the twisting efficiency, and achieve the effect of linear adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

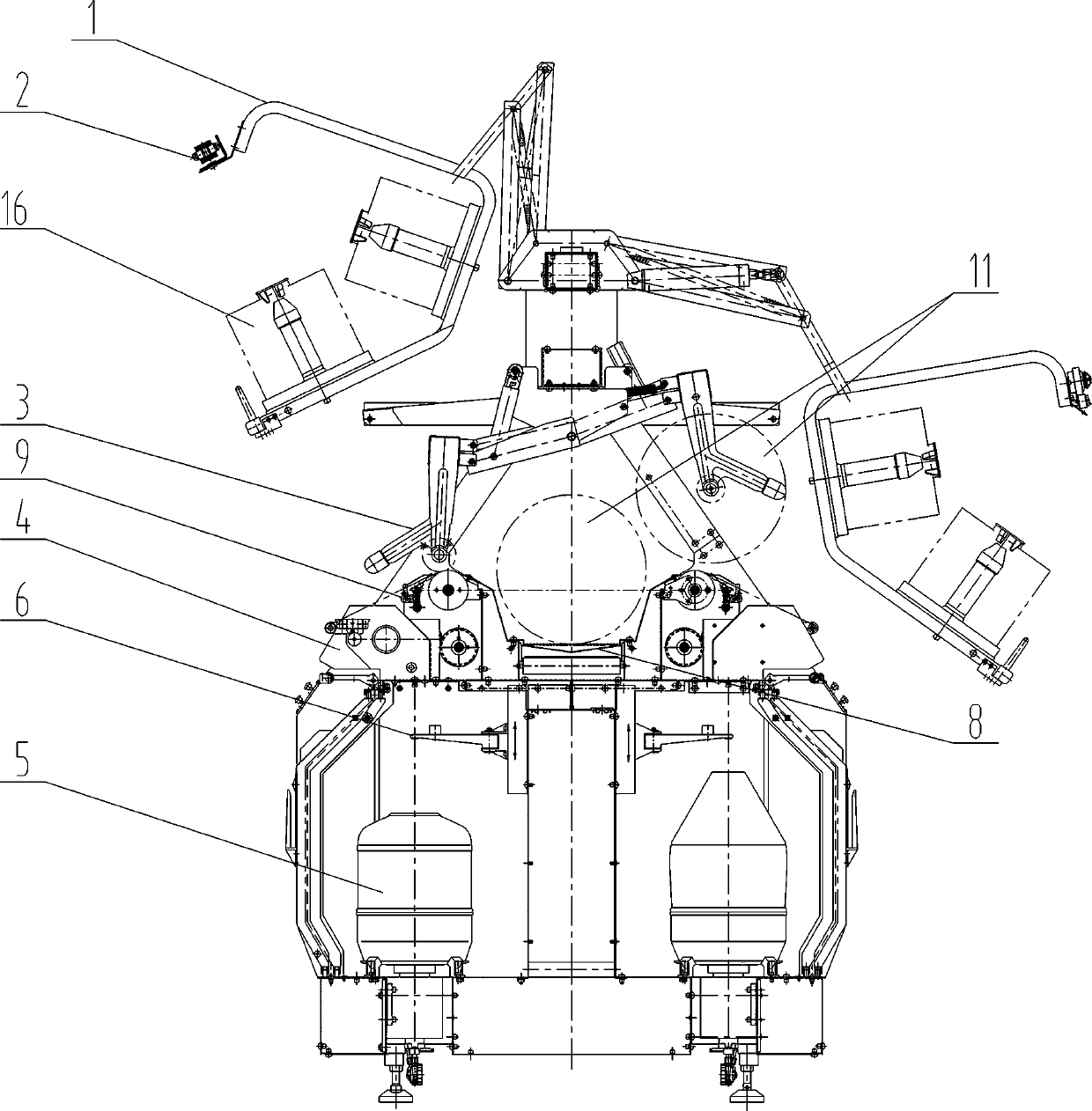

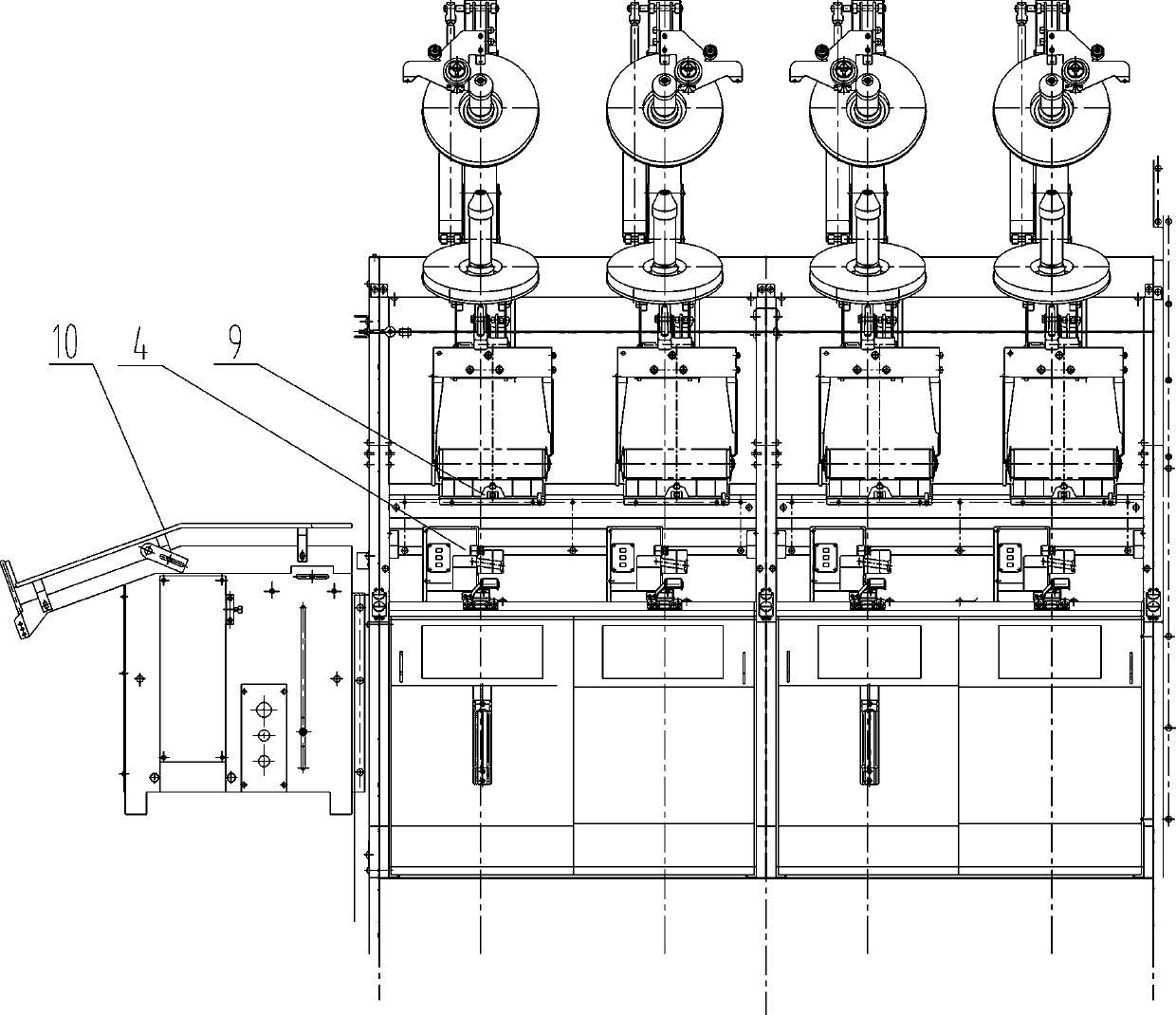

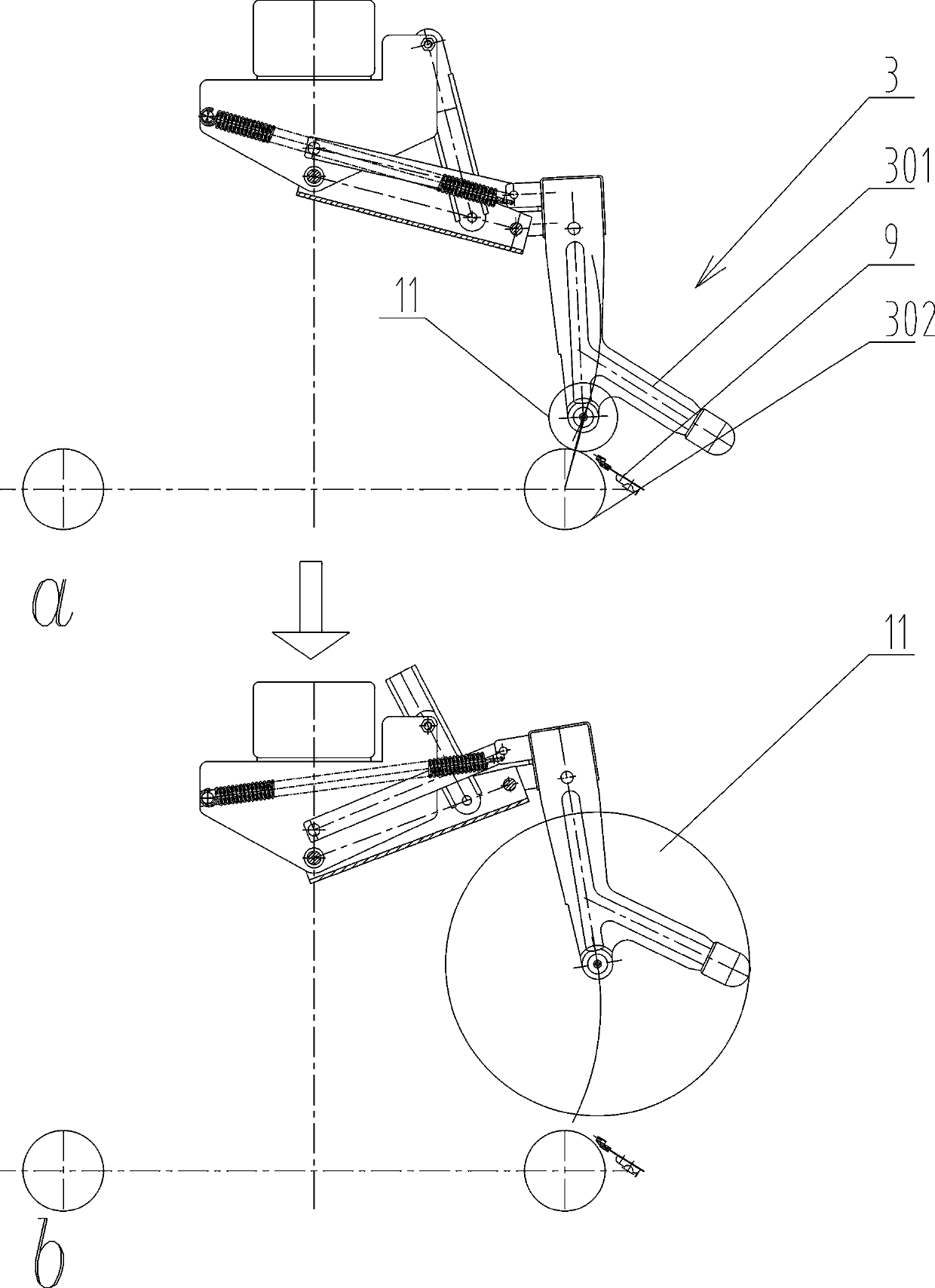

[0045] Such as figure 1 , 2 , 4 to 6, a carpet yarn twisting machine, comprising a frame, a creel device 1, an electric spindle device 5, an overfeeding device 4 and a coiling device 3, in the electric spindle device 5, the hollow spindle bar 502 is fixedly connected with the motor 501. In this example, a synchronous motor is preferably used, and the hollow spindle bar 502 is driven by the motor 501 to rotate. The center of the hollow spindle bar 502 is provided with a yarn path for the outer yarn to pass through, a twisting disc 506 and a yarn storage The disc 505 is fixedly connected with the hollow spindle bar 502 and rotates with the moving hollow spindle bar 502;

[0046] The yarn storage tray 505 is provided with a yarn outlet hole 504 communicating with the inner yarn path of the hollow spindle bar 502 for passing the outer yarn 13 out;

[0047] The spindle pot for accommodating the inner yarn package 15 is connected with the hollow spindle rod 502 through the spindle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com