Double twisting mechanism and working method thereof, and double twisting device

A driving mechanism and twister technology, applied in the field of double twisting device and double twisting mechanism, can solve the problems of large space occupied by rope making equipment, complex twisting structure, low rope making efficiency, etc. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

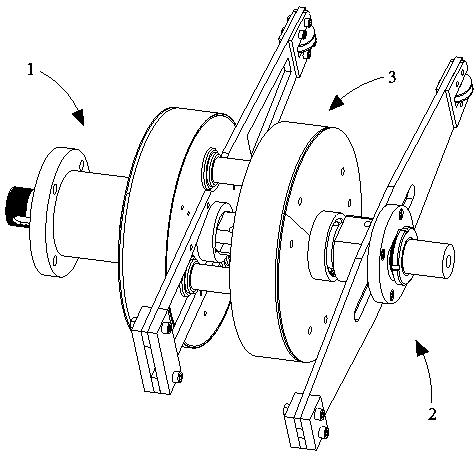

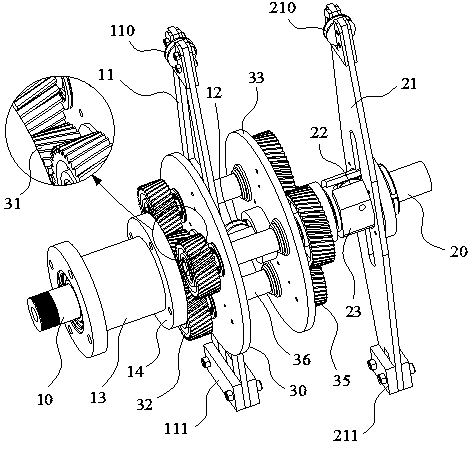

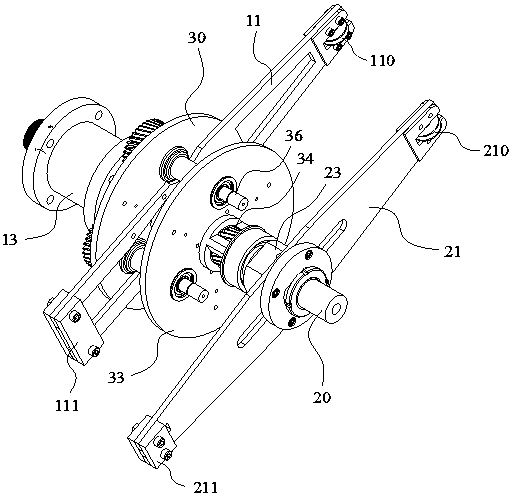

[0025] Such as Figure 1 to Figure 3 As shown, the present embodiment 1 provides a two-for-one twisting mechanism, including: a first twisting sub-mechanism 1 and a second twisting sub-mechanism 2; Several raw yarns are twisted.

[0026] Specifically, the two-for-one twisting mechanism of this embodiment is provided with two twisting sub-mechanisms, that is, the first and second twisting sub-mechanisms, and the first and second twisting sub-mechanisms are used to rotate several raw material yarns in opposite directions. The threads are twisted sequentially to effectively improve the twisting efficiency, thereby effectively improving the rope-making efficiency.

[0027] The two-for-one twisting mechanism also includes: a transmission sub-mechanism 3; when a driving mechanism drives the first twisting sub-mechanism 1 to rotate, the first twisting sub-mechanism 1 is suitable for driving the transmission sub-mechanism 3 to rotate; the transmission sub-mechanism 3 is suitable for...

Embodiment 2

[0045] On the basis of Embodiment 1, this Embodiment 2 provides a working method of a two-for-one twisting mechanism, including: after the first twisting of several raw material yarns through the first twisting sub-mechanism, the second twisting sub-mechanism The mechanism performs the second twisting to make a multi-twist cord.

[0046] Specifically, for the specific structure of the two-for-one twisting mechanism, please refer to the content of Embodiment 1, which will not be repeated here.

Embodiment 3

[0048] On the basis of embodiment 1, this embodiment 3 provides a two-for-one twisting device, including: two sets of two-for-one twisting mechanisms as described in embodiment 1; The first twisting sub-mechanism in the two-for-one twisting mechanism is set close to it, and the second twisting sub-mechanism in the two sets of two-for-one twisting mechanisms is set far away; each raw material yarn is suitable for feeding into the input shaft of the first two-for-one twisting mechanism, and passes through the first twisting mechanism in turn. After the first and second guide wheels of the group are wound out, they are fed into the input shaft of the second group of two-for-one twisting mechanisms through the second and first guide wheels of the second group in turn; and the input shaft of the second group of two-for-one twisting mechanisms Each raw material yarn in the shaft is suitable to be fed into the output shaft of the second group of two-for-one twisting mechanism, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com