Separating and impurity-removing method for graphene oxide

A graphene and graphite technology, applied in the field of graphene oxide preparation, can solve the problems of low efficiency, high energy consumption and high cost of graphene oxide, and achieve the effects of reducing time, improving economic benefits and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

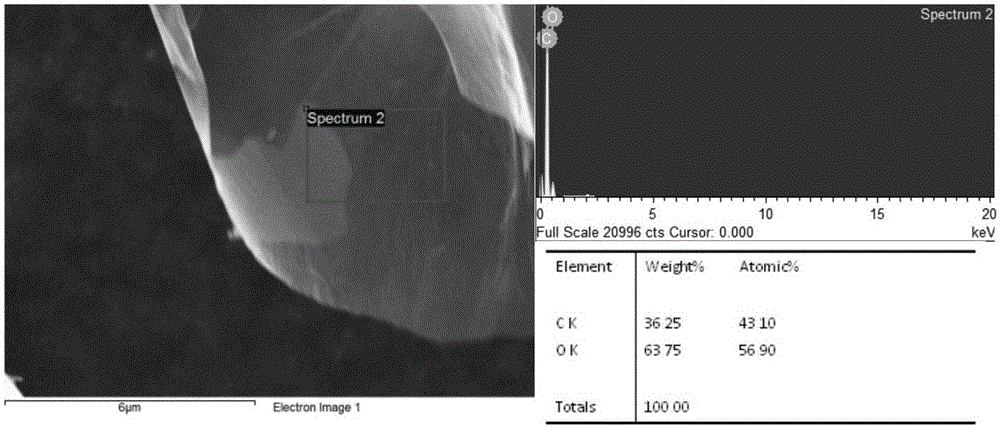

Image

Examples

Embodiment 1

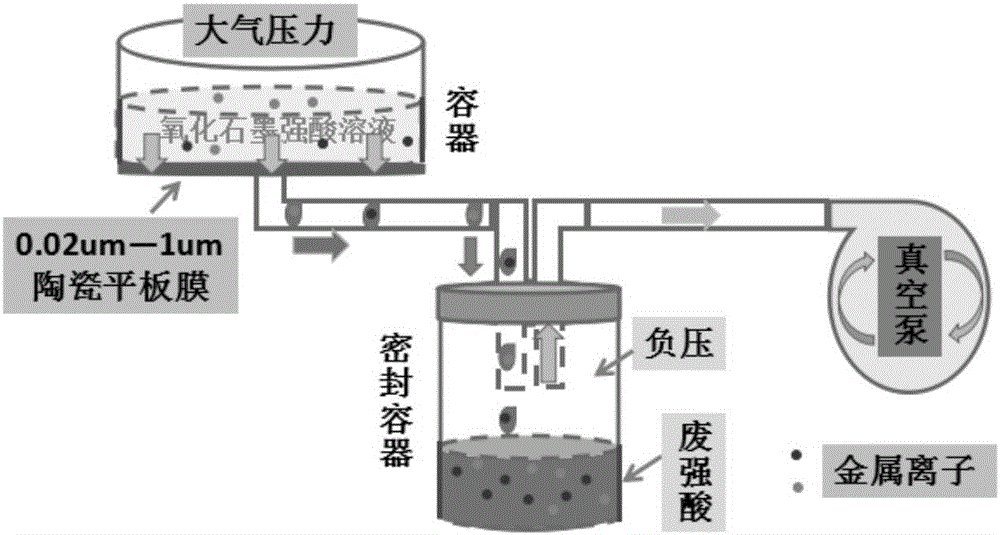

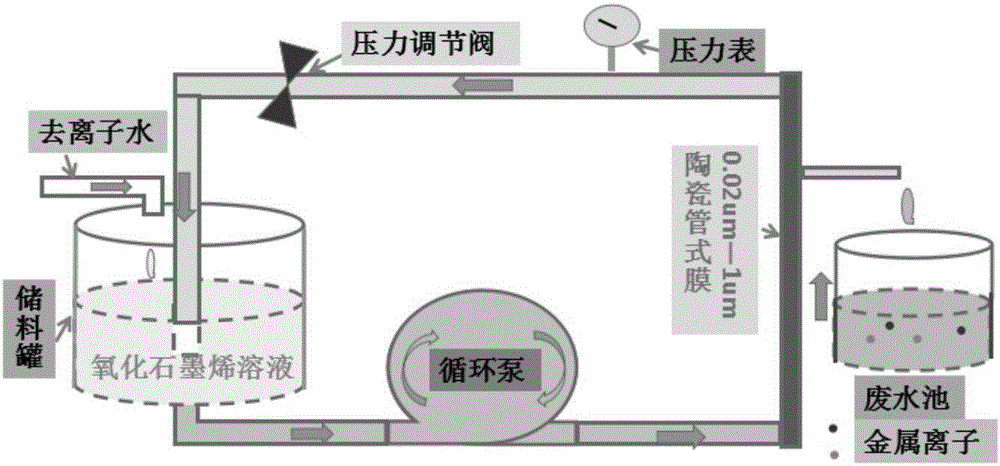

[0025] 1) Preparation of graphene oxide: dry 6g graphite powder at 60°C for 12h; cool 720ml concentrated sulfuric acid and 80ml phosphoric acid to below 5°C, then stir and mix magnetically while dissipating heat; add 6g of dried graphite powder to sulfuric acid / Phosphoric acid mixed acid, stir; slowly add 36g potassium permanganate powder (when adding potassium permanganate must be slow to avoid explosion); after adding potassium permanganate, raise the temperature of the reaction vessel to 60℃, Open the mouth and react for 12 hours. After the reaction is over, cool to room temperature naturally; pour the cooled reaction solution into a container of 800ml solution (containing 10ml, 30% hydrogen peroxide) frozen in advance, and rinse the reaction vessel with the same proportion of dilute hydrogen peroxide solution On the surface, add dilute hydrogen peroxide solution to the container and stir continuously until the solution turns bright yellow, which is the graphite oxide reacti...

Embodiment 2

[0030] 1) Preparation of graphene oxide: Add 15g of sodium nitrate to a container containing 675ml of concentrated sulfuric acid, dissolve the solid under magnetic stirring, then weigh 20g of graphite powder into the above mixed solution, stir evenly, in an ice bath Then slowly add 90 g of potassium permanganate to control the reaction temperature not to exceed 10°C. The reactant was stirred under ice bath conditions for 2 hours and at room temperature for 5 days. After the reaction was completed, 2000 ml of 5 wt% sulfuric acid solution was added for dilution and stirred at room temperature for 2 hours. Then add 60ml of dilute hydrogen peroxide to obtain a yellow reaction solution, and stir for 2 hours at room temperature to obtain a graphite oxide reaction solution;

[0031] 2) With reference to the method of Example 1, the graphite oxide reaction solution is vacuum filtered with a 0.3μm pore size silica ceramic flat membrane to obtain a solid mud cake-like filter cake and filtr...

Embodiment 3

[0035] 1) Preparation of graphene oxide: fully cool the vessel, graphite, potassium permanganate, and concentrated sulfuric acid of the hydrothermal synthesis reactor to 2°C, place the reactor vessel in a stainless steel shell, and add 2.5g graphite and 12.5g After potassium permanganate pour 125ml of concentrated sulfuric acid, quickly cover the reaction kettle and screw it tightly, let the reaction kettle stand at 2℃ for 1.5 hours, take out the reaction kettle and tighten the reaction kettle again and place it in a 100℃ oven for 1.5 hours, take it out After the reaction kettle is naturally cooled, open it, pour the product into 300ml pure water and dilute it, add hydrogen peroxide until the solution turns yellow, which is the graphite oxide reaction liquid;

[0036] 2) With reference to the method of Example 1, the graphite oxide reaction solution was vacuum filtered with an alumina ceramic flat membrane with a pore size of 0.05 μm to obtain a solid mud cake-like filter cake and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com