Pretreatment method for lead plaster of waste lead-acid accumulators

A waste lead-acid battery, pretreatment technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the impact of wet lead recycling process, incomplete separation of lead paste and other components, no technology, etc. problem, to achieve the effect of small investment, low production cost and high impurity removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

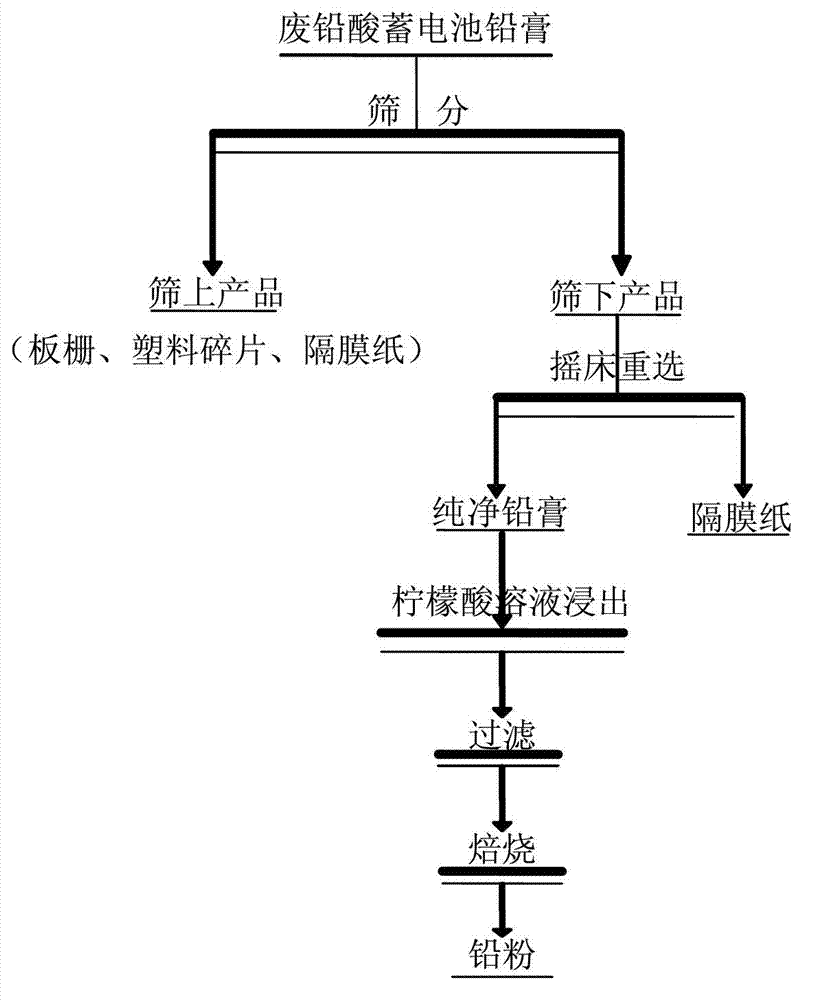

Method used

Image

Examples

Embodiment 1

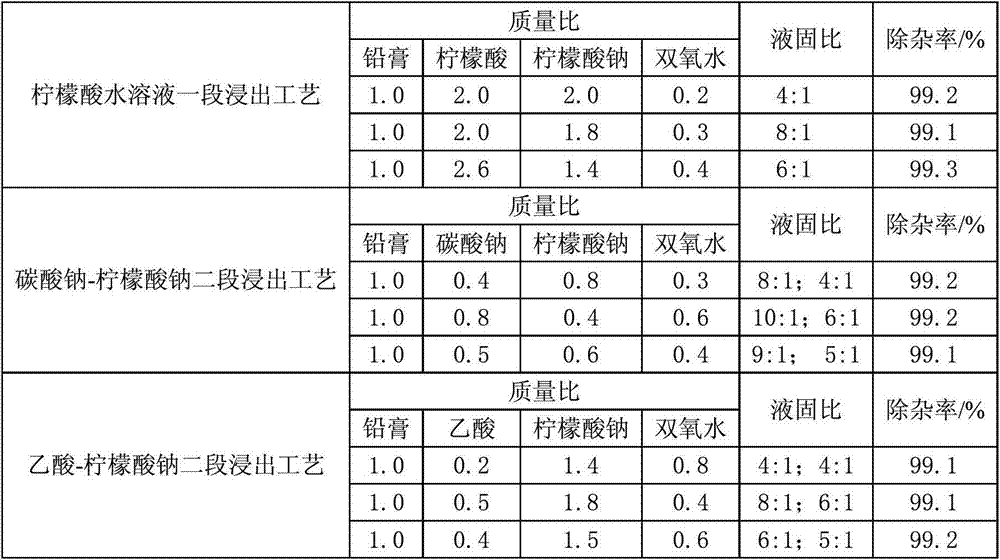

[0029] The waste lead-acid battery is broken and separated to obtain the waste lead paste. Take 10.0 kg of lead paste for waste lead-acid batteries, and sieve it with a 0.85 mm sieve to obtain 2.1 kg of the product on the sieve and 7.9 kg of the product under the sieve. The product under the sieve is re-selected with a shaking table to obtain 0.4 kg of diaphragm paper and 7.5 kg of pure lead paste. Add 37.5L of water, 18kg of citric acid, 13.5kg of sodium citrate, and 2.25kg of hydrogen peroxide to the obtained pure lead paste, stir and leach for 4 hours at room temperature, and filter to obtain lead citrate. Calcined lead citrate in a muffle furnace at 350°C for 1 hour to obtain 5.4kg of lead powder. Lead powder can be directly used to prepare lead-acid batteries. After calculation, the removal rate of waste lead plaster impurities is 99.1%.

Embodiment 2

[0031]Take 5kg of waste lead-acid battery lead paste from a company in Hubei, and sieve it with a 0.25mm sieve to obtain 1.1kg of the product on the sieve and 3.9kg of the product under the sieve. The product under the sieve is re-selected with a shaking table to obtain 0.2 kg of diaphragm paper and 3.7 kg of pure lead paste. Add 37L of water and 2.22kg of sodium carbonate to the pure lead paste, and after leaching for 1 hour, add 2.59kg of citric acid, leaching for 1 hour, and filter to obtain lead citrate. Roast lead citrate in a muffle furnace at 375°C for 2 hours to obtain 2.8kg of lead powder. Lead powder can be directly used to prepare lead-acid batteries. After calculation, the removal rate of waste lead plaster impurities is 99.2%.

Embodiment 3

[0033] Take 15kg of waste lead-acid battery lead paste from a certain company, and sieve it with a 0.106mm sieve to obtain 2.4kg of the product on the sieve and 12.6kg of the product under the sieve. The product under the sieve is re-selected with a shaking table to obtain 0.4 kg of diaphragm paper and 12.2 kg of pure lead paste. Add 61L of water and 4.27kg of acetic acid to the pure lead paste, stir and leach for 6 hours at room temperature, then add 19.5kg of sodium citrate and 7.32kg of hydrogen peroxide, stir and leach for 4 hours at room temperature, and filter to obtain lead citrate. Roast lead citrate in a muffle furnace at 360°C for 3 hours to obtain 9.1kg of lead powder. Lead powder can be directly used to prepare lead-acid batteries. After calculation, the removal rate of waste lead plaster impurities is 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com