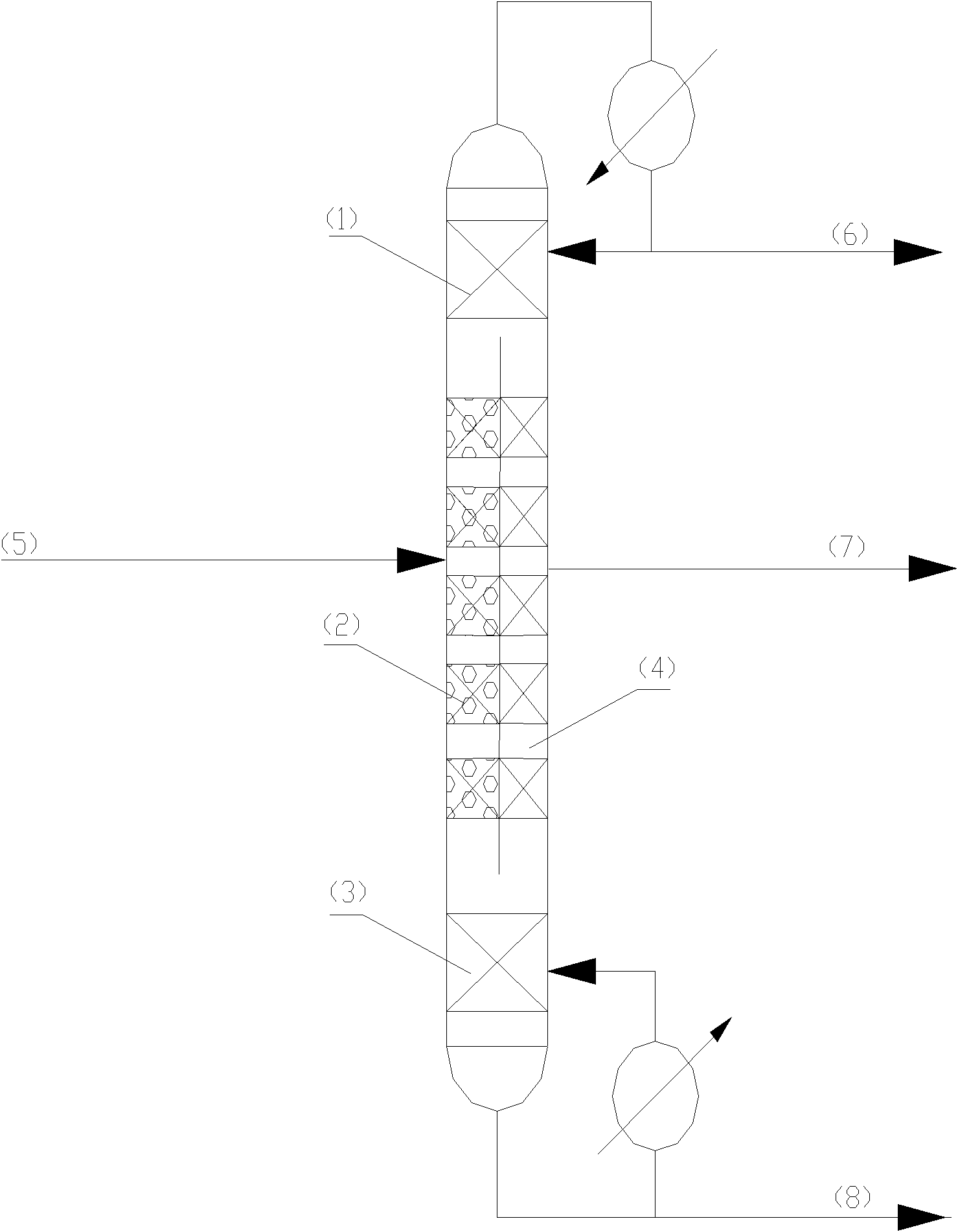

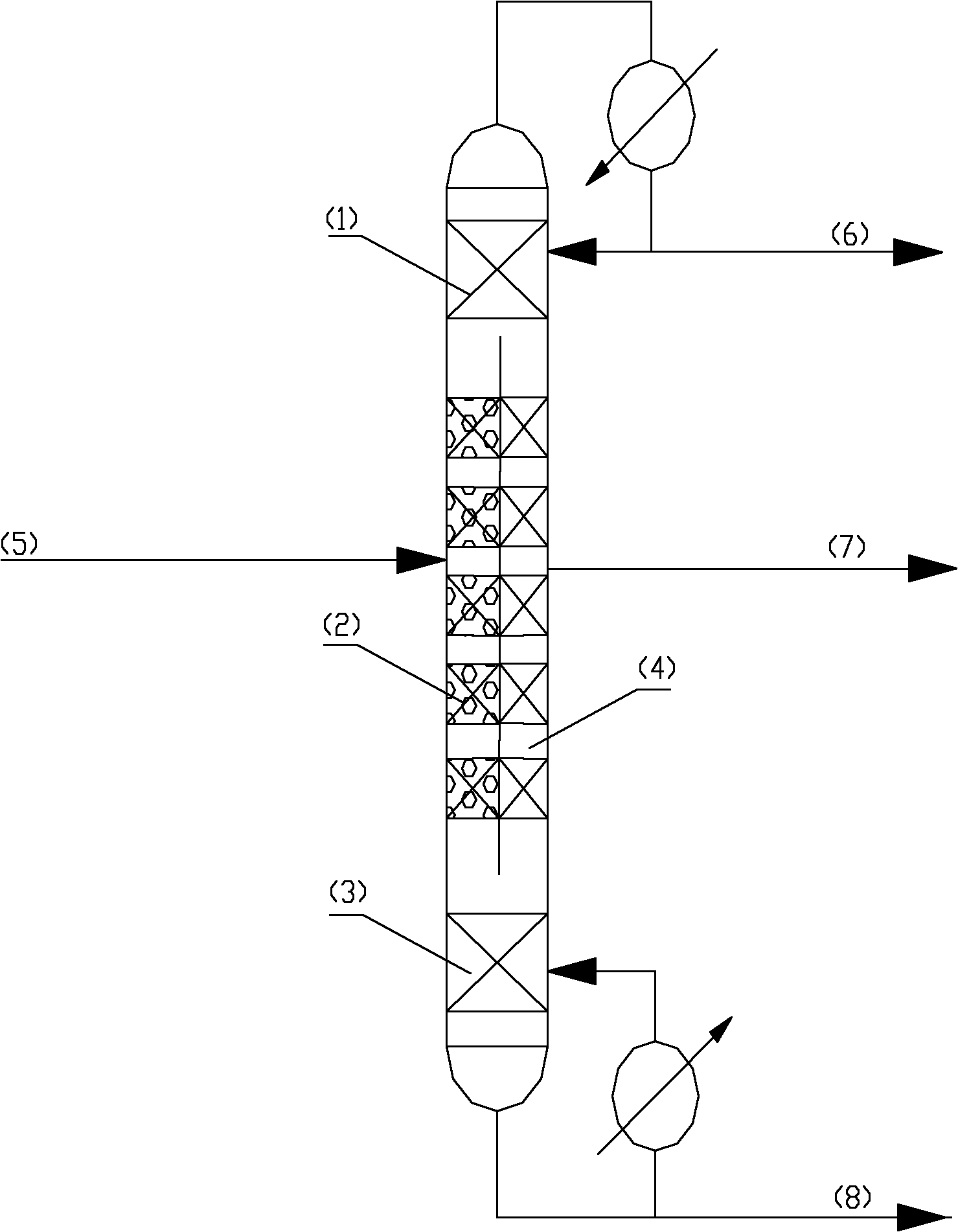

Clapboard adsorption device and method for removing boron impurities in chlorosilane system

An adsorption device and chlorosilane technology, applied in halosilane, separation methods, chemical instruments and methods, etc., to achieve the effects of simplifying the process flow, reducing production costs, and improving the efficiency of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] The chlorosilane system contains 95.0% trichlorosilane, 2.0% silicon tetrachloride, 2.0% dichlorodihydrosilicon, and 1.0% boron trichloride. The throughput of the feedstock was 378.8 kg / hr, which was converted to a molar flow rate of 2.8 Kmol / hr. The tower adsorption section adopts ion exchange resin adsorbent with high adsorption capacity. The main tower adopts metal mesh corrugated packing.

[0023] The pressure at the top of the tower is 300Kpa, the temperature at the top of the tower is 49.2°C, the thermal condition of the feed is 30.0°C bubble point feed, the top of the tower is 0.06Kmol / hr, the side line is 1.99Kmol / hr, and the tower kettle is 0.74Kmol / hr. The condenser The heat load is 0.0120M*kcal / hr, the heat load of the reboiler is 0.0154M*kcal / hr, the number of theoretical plates in the common rectifying section is 19, the number of theoretical plates in the common stripping section is 9, and the number of theoretical plates in the tower adsorption section i...

example 2

[0026] The chlorosilane system contains 98% trichlorosilane, 0.8% silicon tetrachloride, 0.7% dichlorodihydrogen silicon, and 0.5% boron trichloride, and the processing capacity of the raw material is 379.1kg / hr, which is converted into The molar flow rate was 2.8 Kmol / hr. The tower adsorption section adopts zeolite molecular sieve adsorbent.

[0027] The pressure at the top of the tower is 400Kpa, the temperature at the top of the tower is 70.8°C, the thermal condition of the feed is 30.0°C bubble point feed, the top of the tower is taken 0.06Kmol / hr, the side line is taken out 2.0Kmol / hr, the tower kettle is taken out 0.74Kmol / hr, the condenser The heat load is 0.0153M*kcal / hr, and the heat load of the reboiler is 0.0199M*kcal / hr. The number of theoretical plates in the common rectifying section is 19, the number of theoretical plates in the common stripping section is 9, and the number of theoretical plates in the tower adsorption section is 10. The number of theoretical b...

example 3

[0030] The chlorosilane system contains 95.0% trichlorosilane, 2.0% silicon tetrachloride, 2.0% dichlorodihydrosilicon, and 1.0% boron trichloride. The throughput of the feedstock was 378.8 kg / hr, which was converted to a molar flow rate of 2.8 Kmol / hr. The tower adsorption section uses silica gel as the adsorbent.

[0031] The pressure at the top of the tower is 500Kpa, the temperature at the top of the tower is 65.3°C, the thermal condition of the feed is 30.0°C, the bubble point feed, the top of the tower is 0.06Kmol / hr, the side line is 1.99Kmol / hr, and the tower kettle is 0.74Kmol / hr. The condenser The heat load is 0.0143M*kcal / hr, and the heat load of the reboiler is 0.0197M*kcal / hr. The number of theoretical plates in the common rectifying section is 19, the number of theoretical plates in the common stripping section is 9, and the number of theoretical plates in the tower adsorption section is 10. The number of theoretical boards in the outgoing section is 20, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com