Opening and cleaning method for axial flow opener for opening picking or blowing carding process and special composite beater device thereof

A technology of blowing carding, opening and cleaning, which is applied in the field of composite beating devices, can solve the problems of large fiber damage, etc., and achieve the effect of reasonable opening, compact structure and strong rigidity

Active Publication Date: 2010-08-25

CHTC HEAVY IND +1

View PDF7 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

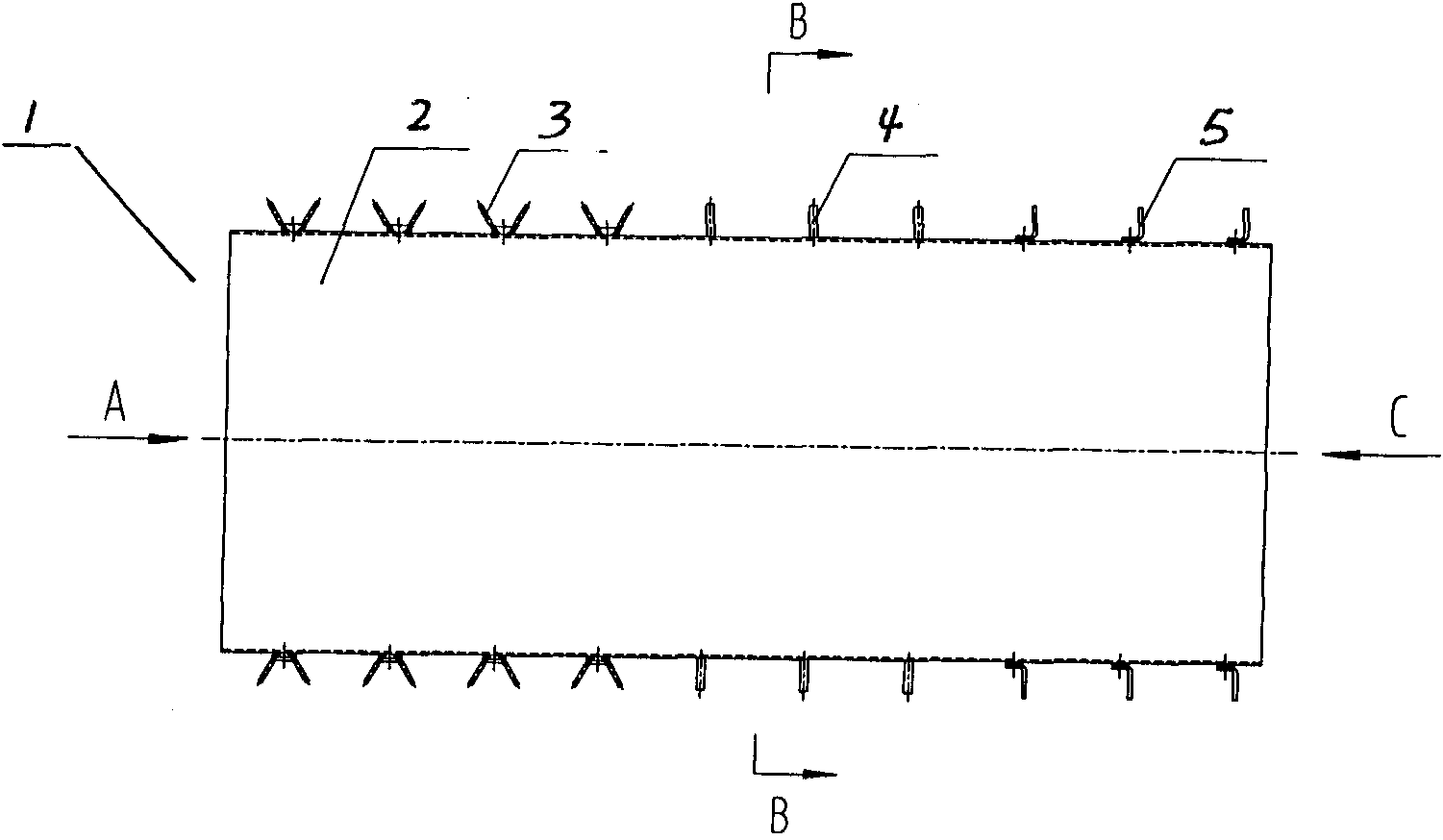

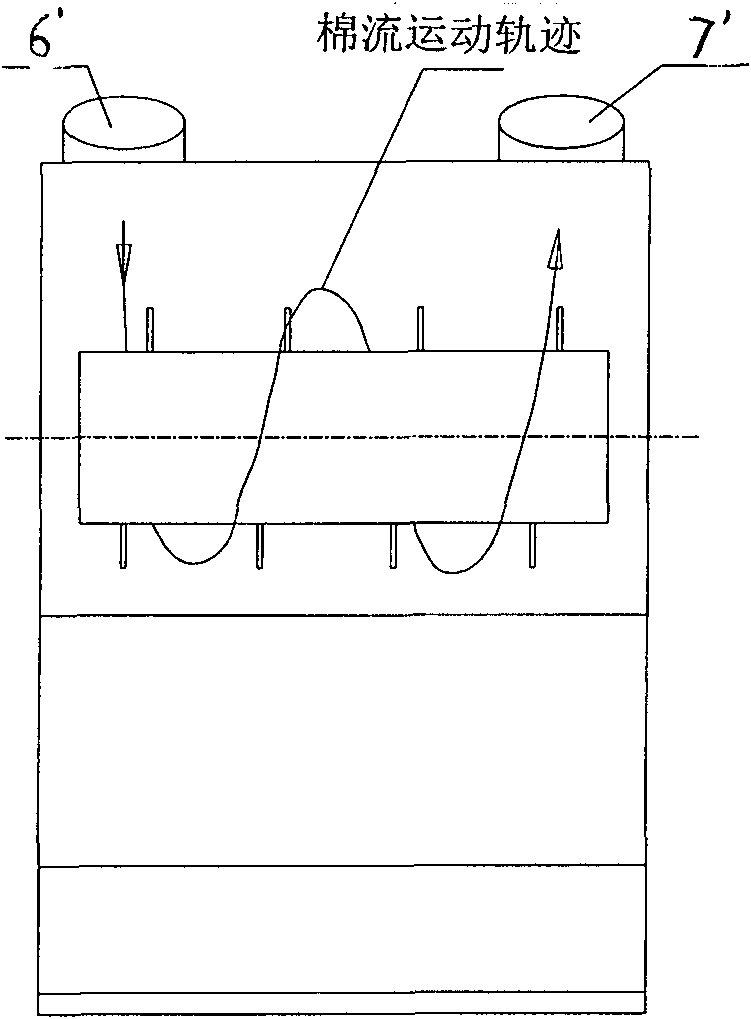

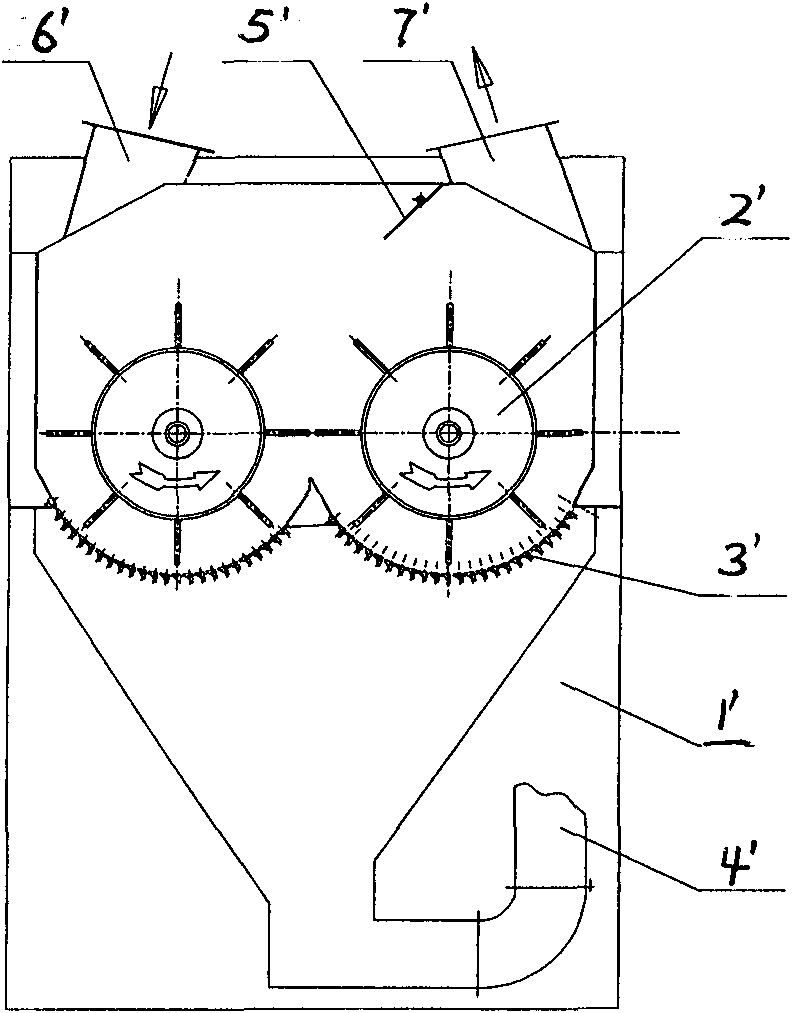

The invention provides an opening and cleaning method for an axial flow opener for opening picking or blowing carding process, and a special composite beater device. The method comprises the step that a cotton block to be opened makes spiral movement along beaters under common action of the beaters and air flow after the cotton block to be opened is fed into a beater chamber. The method is characterized in that the cotton block is subjected to opening and cleaning in different beating modes in turns when the cotton block makes spiral movement from a cotton inlet to a cotton outlet. The special composite beater device comprises beater cylinders, and is characterized in that the beater cylinders are provided with a blade region, a bar-shaped brad region and a V-shaped brad region in sequence from the inlet end to the outlet end. A reducing mode that the beater outer diameter is reduced from the inlet to the outlet in turns is adopted, so distances between beaters and grid bars are increased from the inlet to the outlet in turns to adapt to the condition that the cotton block is gradually opened and expanded in the forwarding process. The method has reasonable opening mode, high cleaning efficiency and fiber destruction prevention, and achieves the effect of developing strong points and avoiding weak points compared with the prior art.

Description

The method of opening and removing impurities and its special compound beating device for axial flow openers in the process of opening and cleaning cotton or blowing and carding (1) Technical field The invention relates to the field of textile machinery, in particular to an opening and cleaning method for an axial-flow opener in a blowing-carding process and a special compound beating device thereof. (2) Background technology The cotton opener is one of the main equipment in the process of opening and cleaning or blowing and carding. It will loosen and remove impurities from the delivered cotton block to meet the needs of the next spinning process. At present, there are mainly two types of cotton openers: one is the "free opening type" in which raw cotton is fed into the beating chamber by airflow, such as six-roller openers, axial flow openers, etc. It is generally used for preliminary opening and impurity removal of fibers. The other type is the "holding and opening t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01G9/06D01G9/14

Inventor 刘延武邢怀祥段保强张小平郭东亮丁惠敏成志勇常尧

Owner CHTC HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com