Rotating disc type grain discharging and storing device

A storage device and turntable technology, which is applied in the field of grain processing, can solve the problems of debris and dust flying around, no dust removal, impurity removal, etc., and achieve the effect of improving the dust removal effect, simple structure, and increasing the dust removal area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

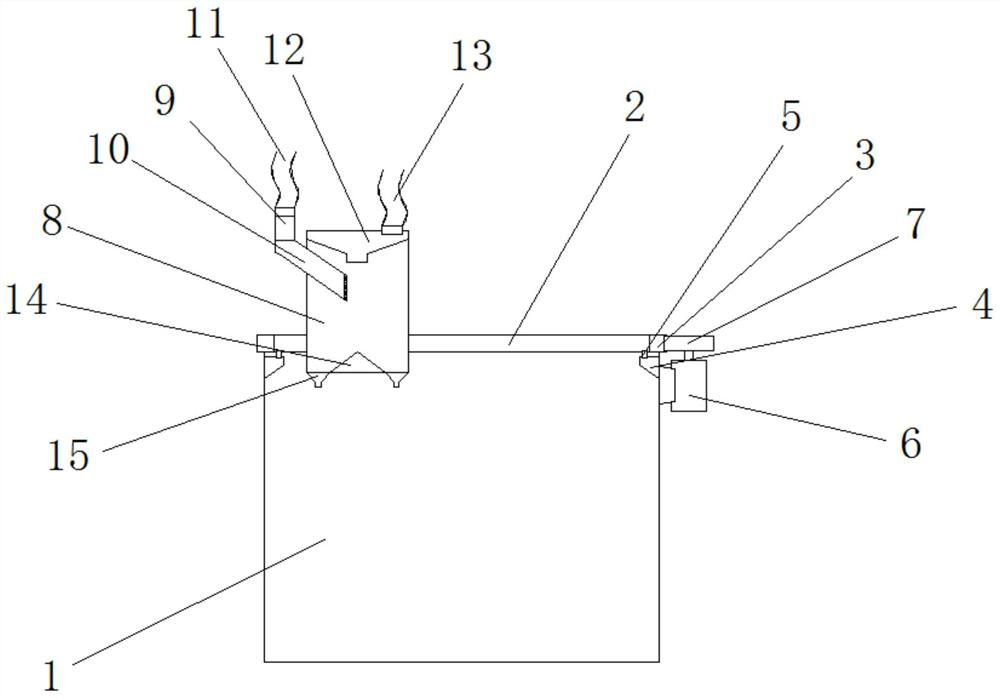

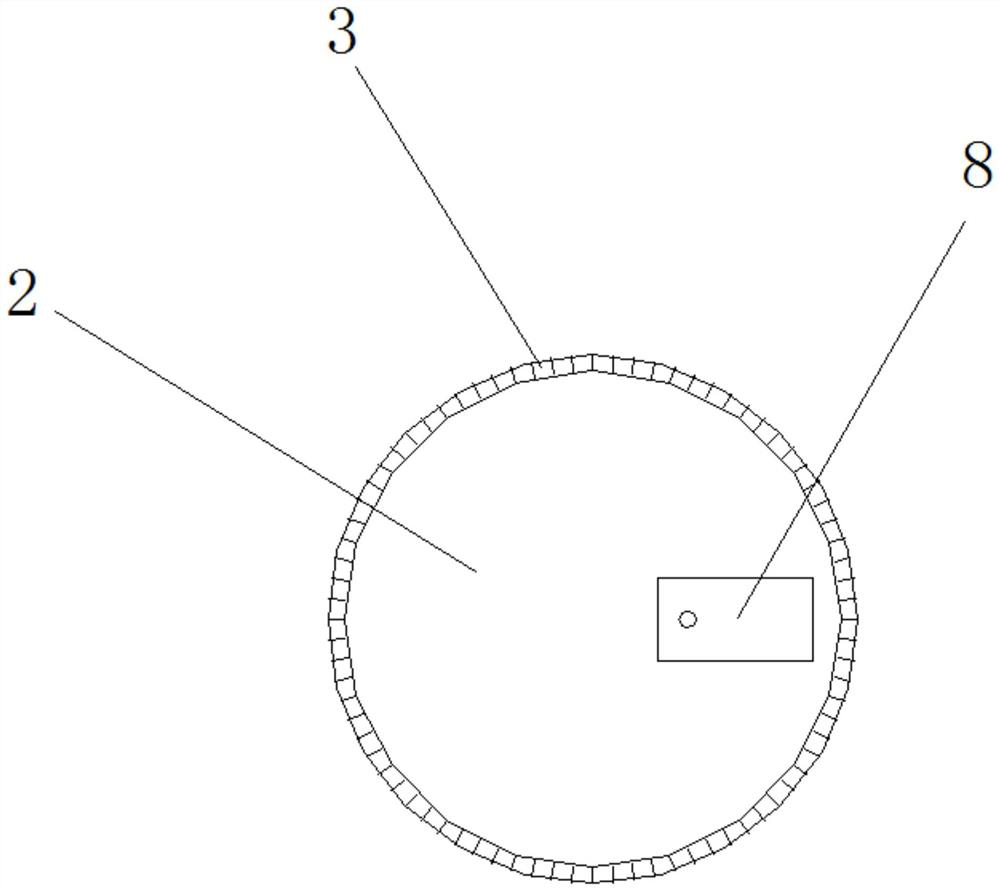

[0018] Embodiment 1: as Figure 1-4 As shown, a turntable type grain blanking storage device includes a silo 1, the silo 1 is arranged in a barrel shape, and an annular track 4 is fixedly installed on the top of the inner cavity of the silo 1, and the annular track 4 The top of the silo 1 is rotatably connected with a turntable 2, the outer side of the turntable 2 is fixedly connected with a ring gear 3, the top side wall of the silo 1 is fixedly installed with a motor 6, and the top of the motor 6 is fixedly connected with a gear 7. The gear 7 meshes with the ring gear 3;

[0019] The motor drives the gear to rotate, so that the ring gear on the side wall of the turntable drives the turntable to rotate, and the lower silo unloads the material into the hopper during the process of following the rotation of the turntable, and distributes it evenly in the hopper, thus playing the function of storage and avoiding There is a situation of accumulation.

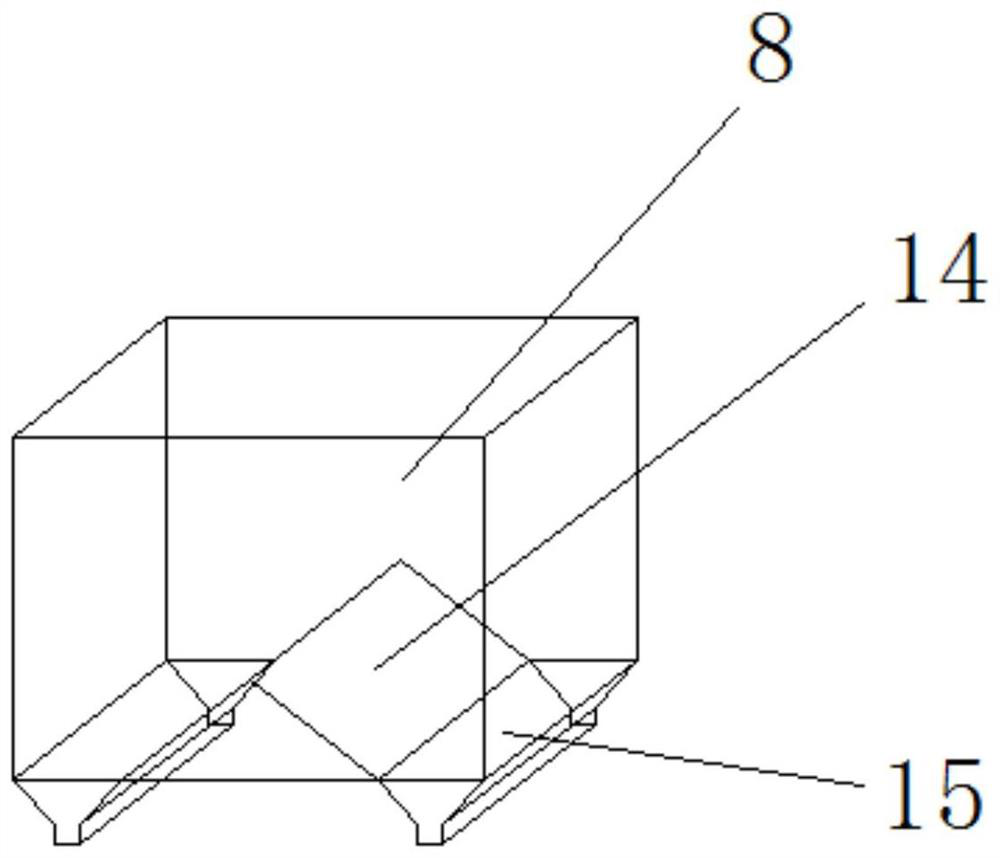

[0020] A lower hopper 8 i...

Embodiment 2

[0025] Embodiment 2: as Figure 1-4 As shown, a turntable type grain blanking storage device includes a silo 1, the silo 1 is arranged in a barrel shape, and an annular track 4 is fixedly installed on the top of the inner cavity of the silo 1, and the annular track 4 The top of the silo 1 is rotatably connected with a turntable 2, the outer side of the turntable 2 is fixedly connected with a ring gear 3, the top side wall of the silo 1 is fixedly installed with a motor 6, and the top of the motor 6 is fixedly connected with a gear 7. The gear 7 meshes with the ring gear 3;

[0026] The motor drives the gear to rotate, so that the ring gear on the side wall of the turntable drives the turntable to rotate, and the lower silo unloads the material into the hopper during the process of following the rotation of the turntable, and distributes it evenly in the hopper, thus playing the function of storage and avoiding There is a situation of accumulation.

[0027] A lower hopper 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com