Vibrating device for precast concrete stairs

A technology of precast concrete and vibrating device, which is used in the manufacture of tools, ceramic molding machines, molds, etc., can solve the problems of inconvenient mass operation, low work efficiency, high labor intensity, etc., so as to reduce the investment of manpower and time, and reduce labor. Strength, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

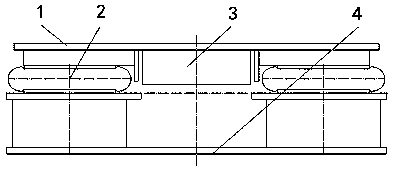

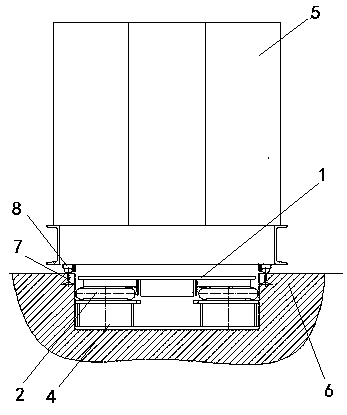

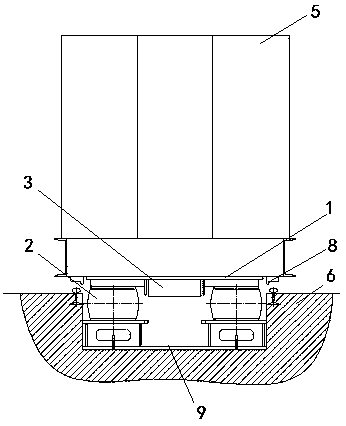

[0020] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention provides a vibration device for precast concrete stairs, which is used for a staircase mold 5, including at least one set of vibration unit assemblies 10, the vibration unit assembly 10 includes a lifting part and a vibrating part, and the lifting part includes a vibrating Pedestal 4, shock-absorbing airbags 2 and air compressors arranged on the left and right sides of the vibration pedestal 4, the shock-absorbing airbags 2 are respectively connected to the air compressors through pneumatic hoses, and the outlet of the air compressors is provided with two, three Air-ventilating solenoid valve; the vibrating part includes a vibrating table 4 and a vibrating motor 3, the vibrating motor 3 is installed on the lower end face of the vibrating table 1, and the upper end of the shock-absorbing air bag 2 is fixedly connected with the vibrating table 1 by bolts, The lower end is fixedly connected with the vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com