Deeply-dehydrated sludge homogenizing discharge device for sewage plant plate-frame machines

A technology of deep dehydration and unloading device, which is applied in the direction of transportation, packaging, loading/unloading, etc., and can solve problems such as unbalanced loading of boxes, waste of manpower and material resources, waste of transport capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

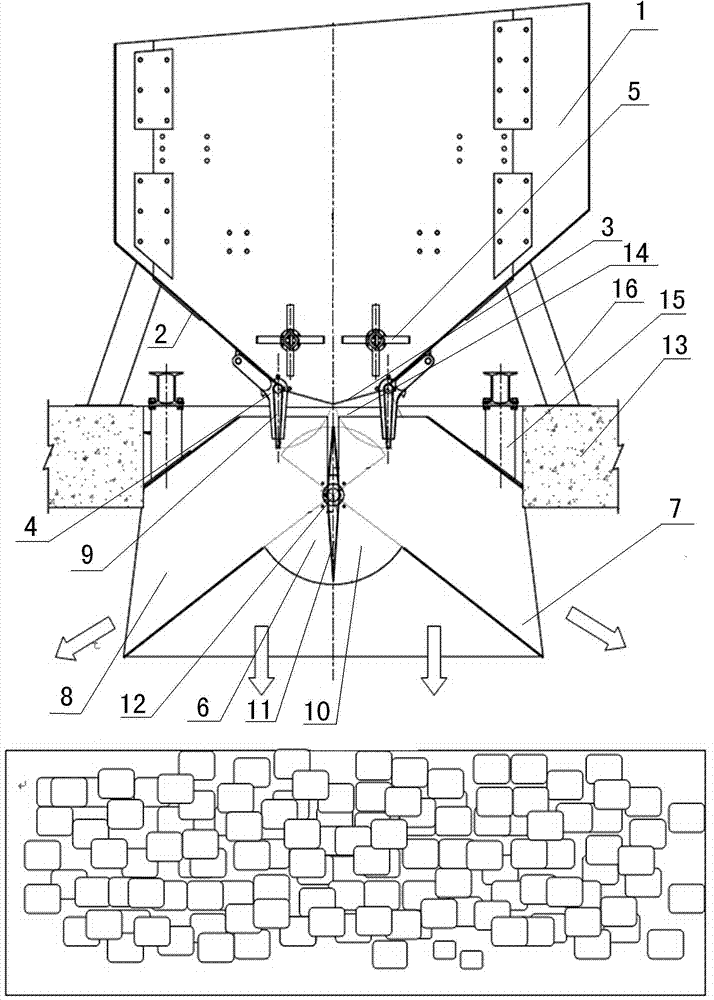

[0024] The present invention will be further described below with reference to the accompanying drawings.

[0025] The present invention is a deep dewatered sludge homogeneous unloading device for a plate and frame machine in a sewage plant, which includes an upper hopper 1, which is different from the prior art in that: both sides of the lower end of the upper hopper 1 form an oblique inner side Distributed hopper walls 2, a lower feed opening 3 is formed between the lower ends of the hopper walls 2 on both sides, and an opening and closing valve 4 is provided at the lower end of the feeding opening 3. The opening and closing valve 4 is composed of two symmetrically distributed valve pieces 9 on the left and right. There is a group of cross material shifting rollers 5 in the upper hopper 1 above the material opening 3, and the cross material setting rollers all rotate inward, which has the effect of moving the material. Both sides of the chute feeding mechanism 6 are obliquel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com