Flexible vertical grinder

A vertical mill, flexible technology, applied in the field of grinding machines, to achieve the effect of stable material bed, good rigidity and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

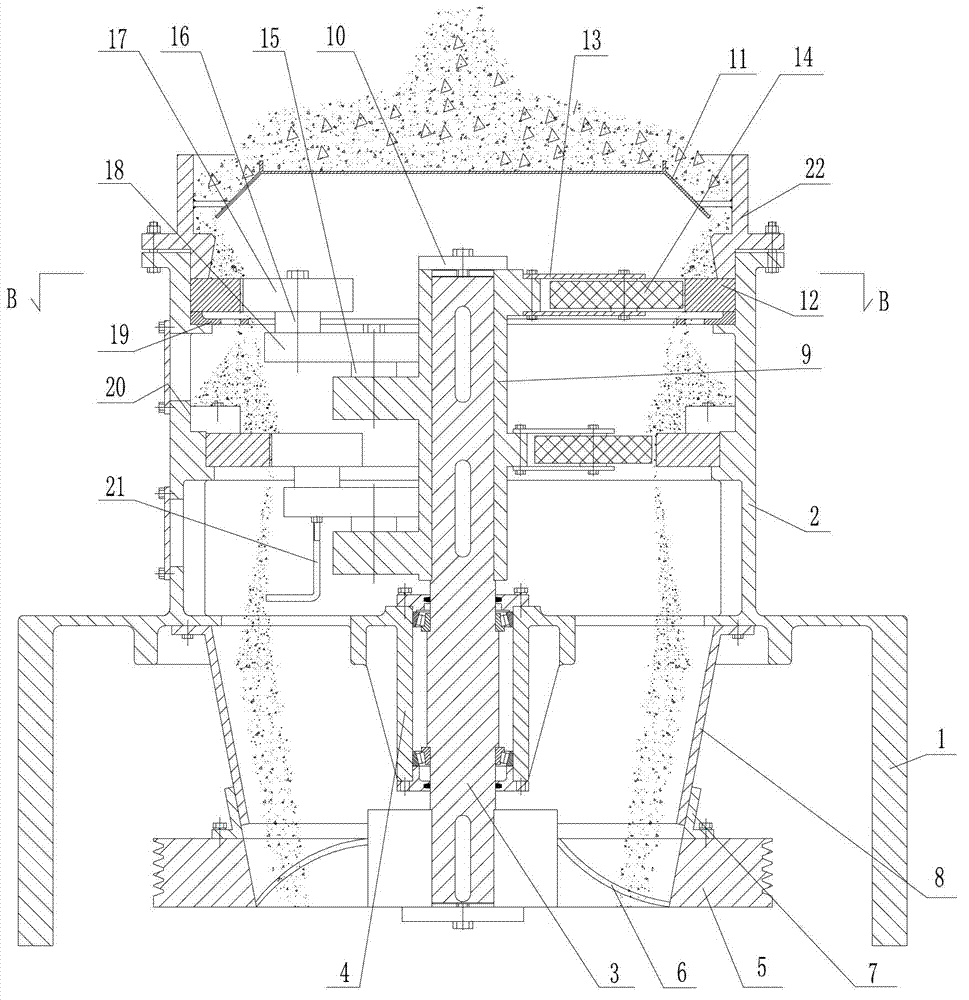

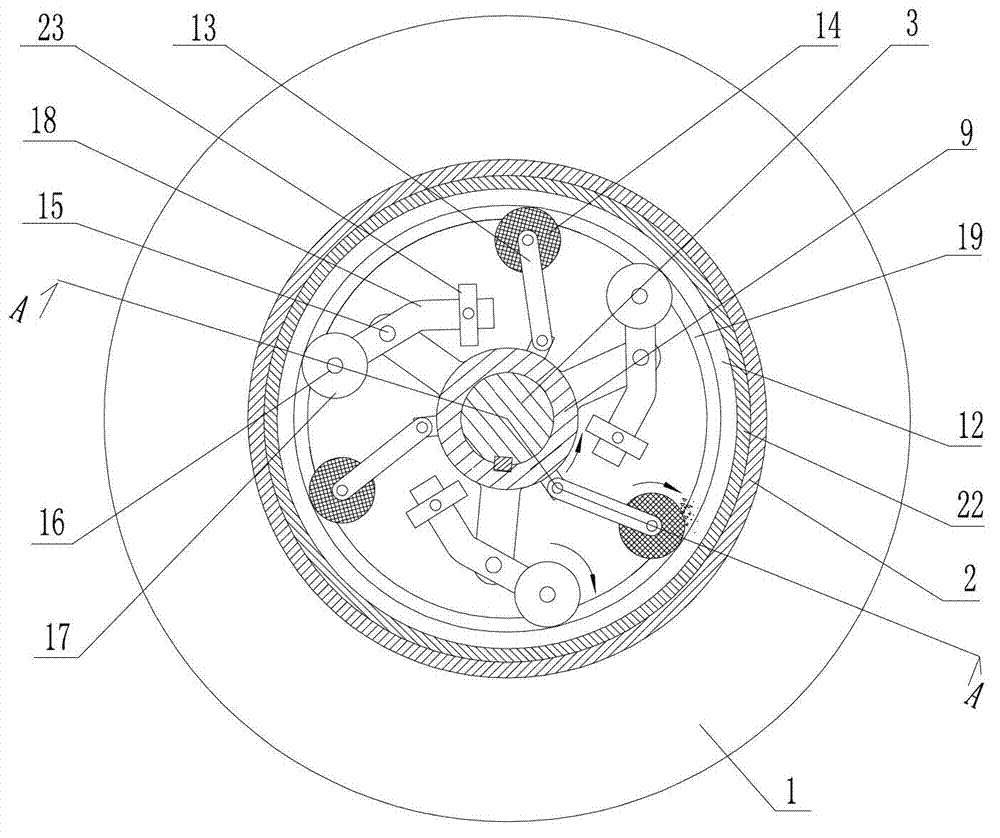

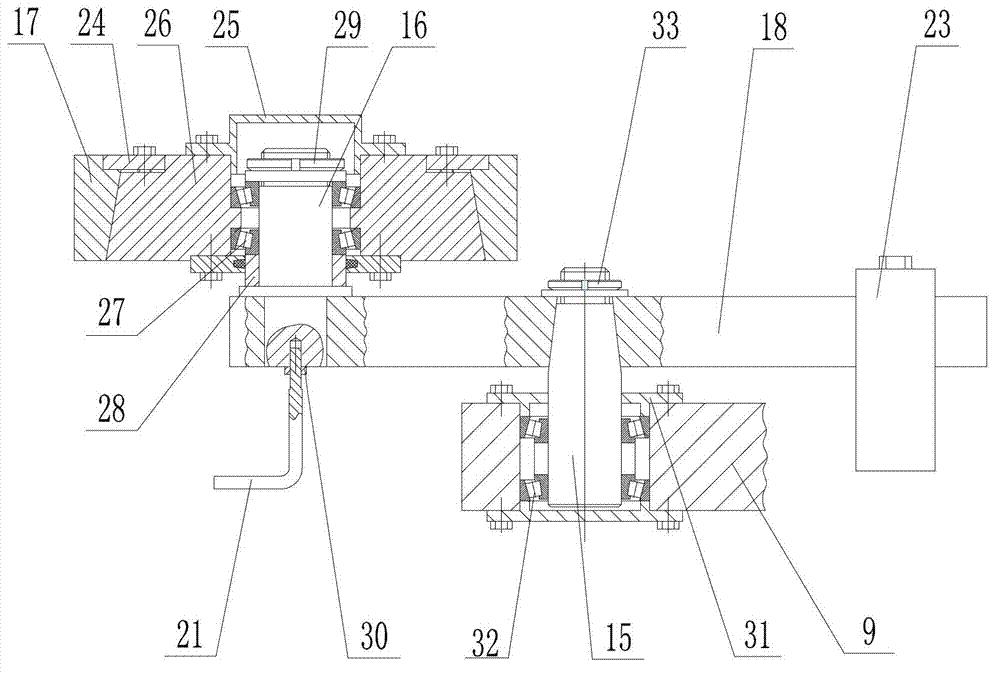

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown in the figure, a flexible vertical mill has a casing 2 fixed on a frame 1, a main shaft mounting frame 4 on the frame 1, a main shaft 3 is installed in the main shaft mounting frame 4, and a large Belt pulley 5, the spoke 6 of big belt pulley 5 is lower helical spoke; The lower end of casing 2 in frame 1 is equipped with lower hopper 8, and there is receiving hopper 7 on the upper side of big belt pulley 5 inner ring outer edge, and receiving hopper 7 is covered under The outer surface of the lower end of the hopper 8; an arched feed hopper 11 is installed on the upper end of the casing 2; a star-shaped bracket 9 is installed on the main shaft 3 in the casing 2, and the upper end of the star-shaped bracket 9 is fixed on the main shaft 3 with a pressure plate 10 , a hammer wheel milling device and a material balance wheel device are housed in the star bracket 9; the hammer wheel millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com