Directional straw spreading machine

A paving machine and directional mechanism technology, which is applied to household components, flat products, household appliances, etc., can solve the problems of complex design of directional paving machines, restrictions on the quality of composite boards, and low strength of composite boards, and achieve simple structure and good appearance. Beautiful appearance and low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

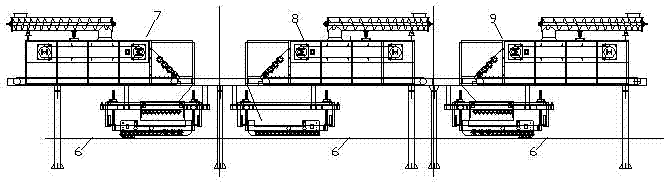

[0031] Such as figure 1 The straw directional paving machine shown comprises the first paving head 7, the second paving head 8 and the third paving head 9 arranged side by side successively from left to right, at the first paving head 7, A conveyor belt 6 is provided below the second paving head 8 and the third paving head 9 .

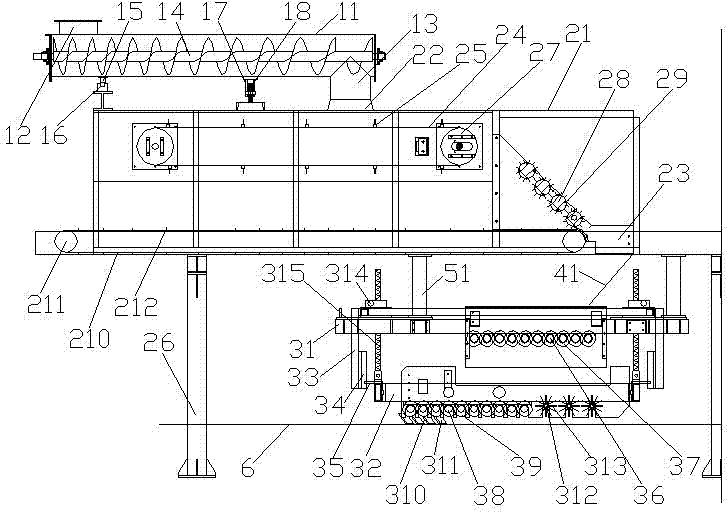

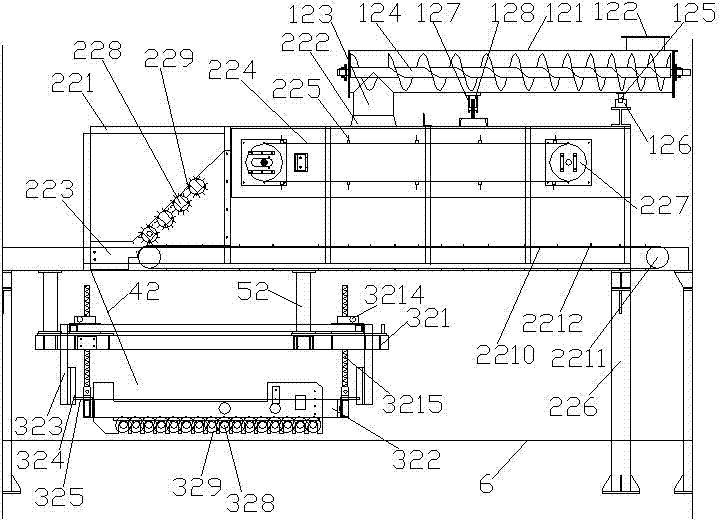

[0032] Such as figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , The first pavement head 7 includes a first feeding mechanism, a first bunker mechanism and a first orientation mechanism. The first feeding mechanism comprises a first material barrel 11 with a first material inlet 12 and a first material outlet 13 and a first feed auger 14 installed in the first material barrel 11, in the first material barrel 11. A first swinging roller 18 is provided through the first bracket 17 under one end of the first discharge port 13, and a first rotating shaft 15 is arranged under the other end of the first barrel 11. The first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com