Positive displacement quantitative filling machine for sliced mushroom

A volumetric, filling machine technology, applied in packaging, transportation and packaging, packaging item types, etc., can solve the problems affecting the quantitative accuracy of material filling, large filling quantitative errors, high labor intensity, etc., to reduce labor The effect of strength, improved fluidity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

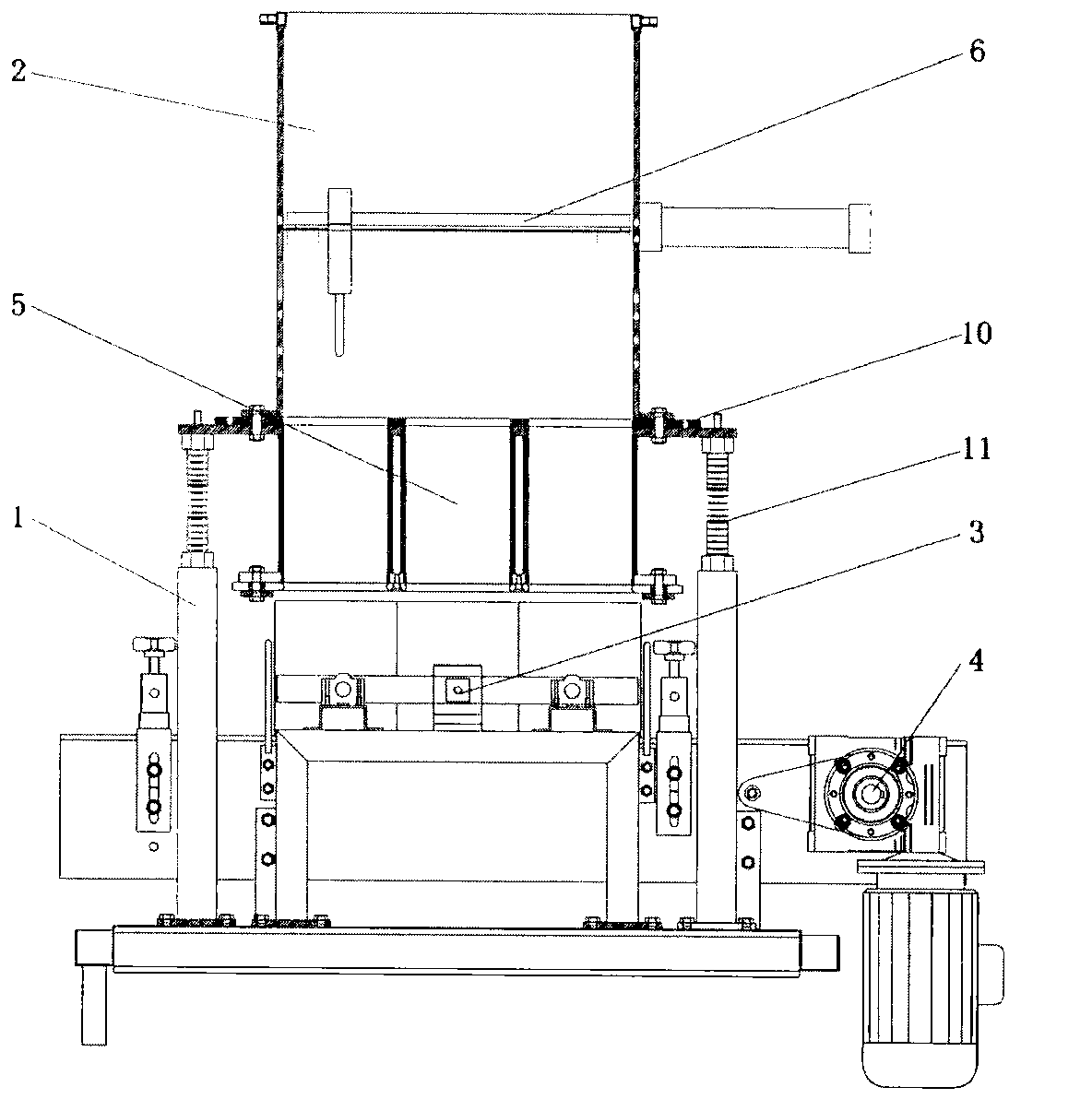

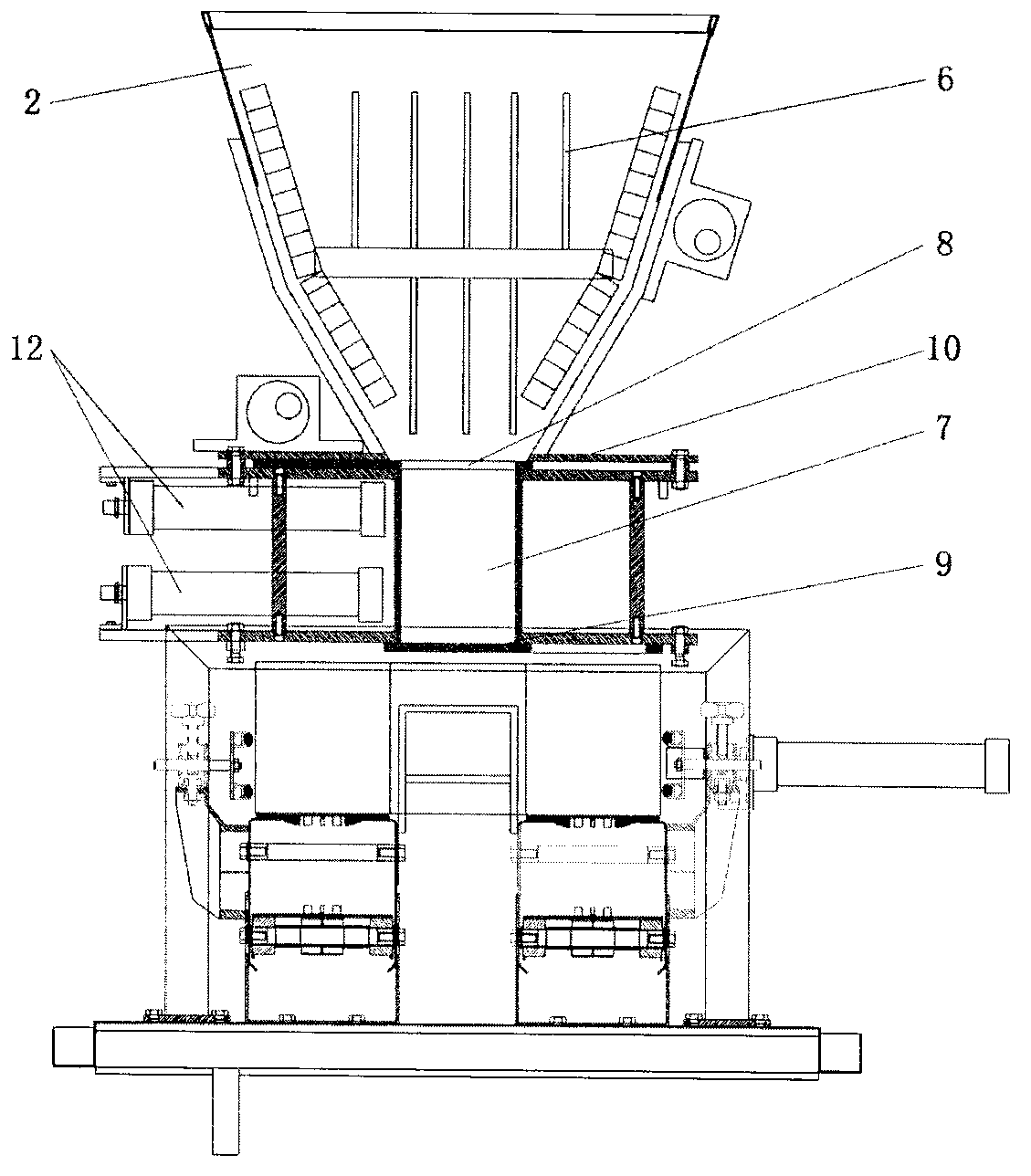

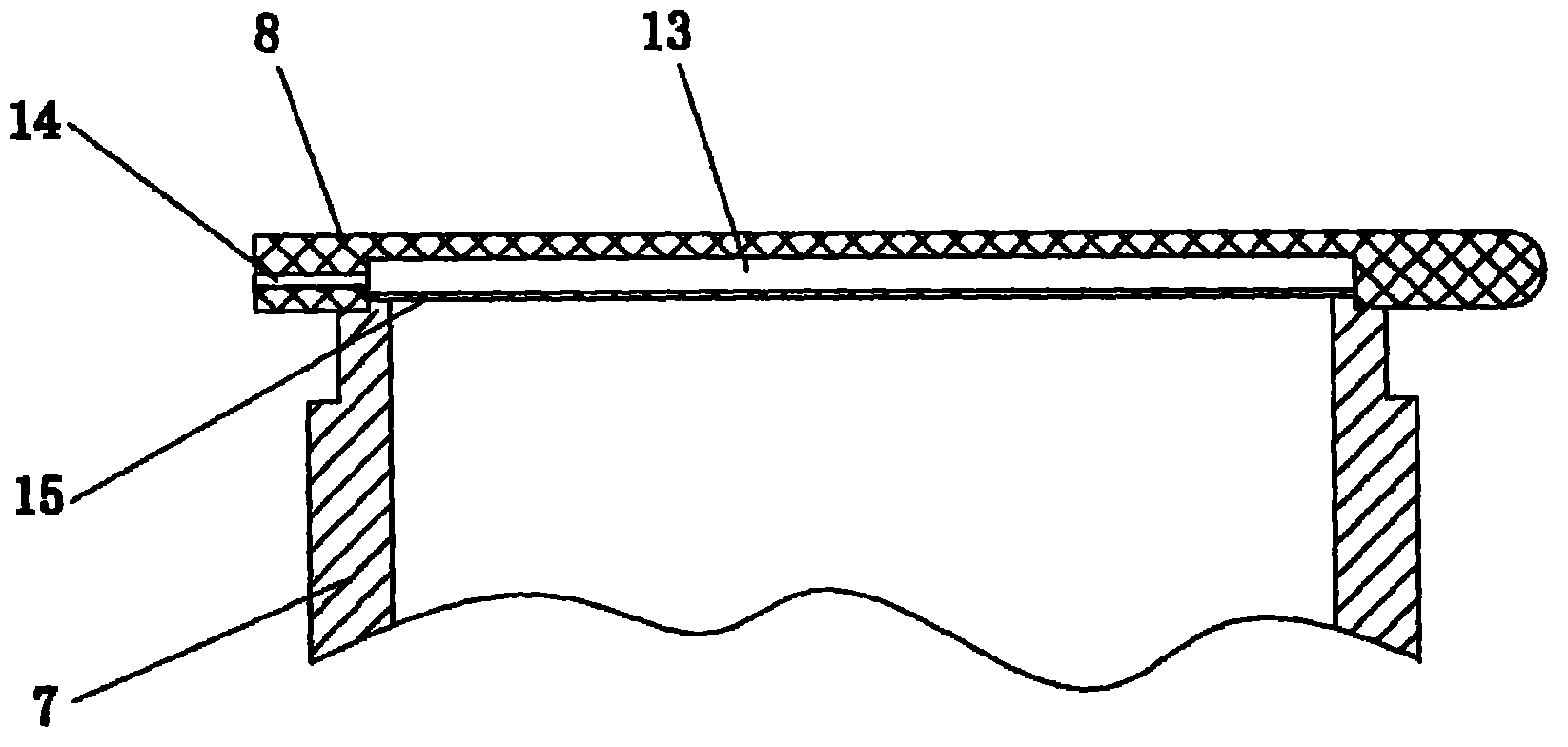

[0029] Such as figure 1 with figure 2 The straight-line mushroom quantitative filling machine (suitable for low-speed and large-capacity) shown in the figure has an overall structural composition: support 1, fixed material box 2, tank conveying device, quantitative filling device 5, raking device 6 and base (this is omitted in the figure). The quantitative filling device 5 includes a quantitative cup 7, an upper sealing plate 8 and a lower sealing plate 9. The upper and lower openings of the quantitative cup are respectively provided with an upper sealing plate and a lower sealing plate, and the upper and lower sealing plates are driven by a cylinder 12 to realize reciprocating motion. . The quantitative cup 7 and the material box 2 are integrally installed on the support plate 10 . The support plate 10 is connected with the bracket 1 through the spring seat 11, so as to realize the overall vibration of the material box and the quantitative cup adaptively, and also make th...

Embodiment 2

[0035] Such as Figure 7 with Figure 8 Shown rotary type sheet mushroom quantitative filling machine (suitable for high-speed small capacity), its overall structure consists of: support 21, quantitative filling device 22, tank delivery device, raking device and base (this is omitted among the figures). A hopper 27 is arranged on the top of the quantitative filling device 22, and a raking device (not shown) is arranged at the lower outlet of the hopper. The main body of the rotating stand is the main shaft 26 . The tank delivery device includes a tank-in puller 23, a tank-out puller 24, and a tank-separating screw shaft 25.

[0036] Such as Figure 9 As shown, the quantitative filling device 22 is made up of a quantitative cup 28 and a rotary feed box 29. A plurality of discharge openings are arranged on the circumference of the material box. On top of the main shaft 26, a support plate 30 is installed. Quantitative filling device 22 is driven to rotate by the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com