Heat-conducting filler containing crystalline flake graphite, and preparation method and application of heat-conducting filler

A technology of flake graphite and thermal conductive filler, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as poor mechanical properties and difficult processing, and achieve the effect of improving production efficiency, broadening application scope, and continuous and stable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

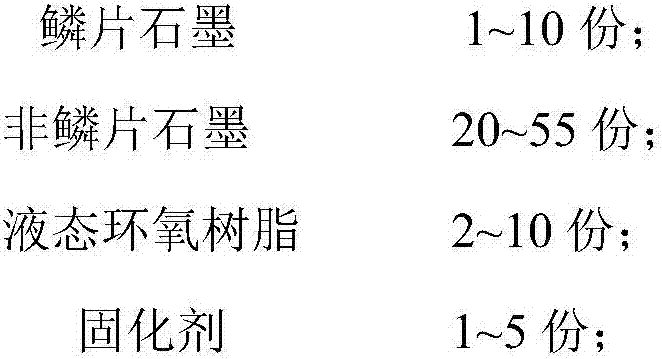

[0030] Preparation of graphite thermally conductive filler: Weigh 6 parts by weight of flake graphite powder with a D50 particle size of 8.56 μm and 24 parts by weight of non-flake graphite powder with a D50 particle size of 175 μm, and mix them uniformly at a high speed at 80°C to obtain a graphite mixture; Take 5 parts by weight of low-viscosity bisphenol A liquid epoxy resin into the planetary power mixer, heat it up to 100°C, and slowly put the graphite mixture into the planetary power mixer in 3 times under stirring, and stir to make After the uniform and viscous mixture is put into 2 parts by weight of tetrakis (2-hydroxyethyl) adipamide curing agent, continue to stir to a small block paste.

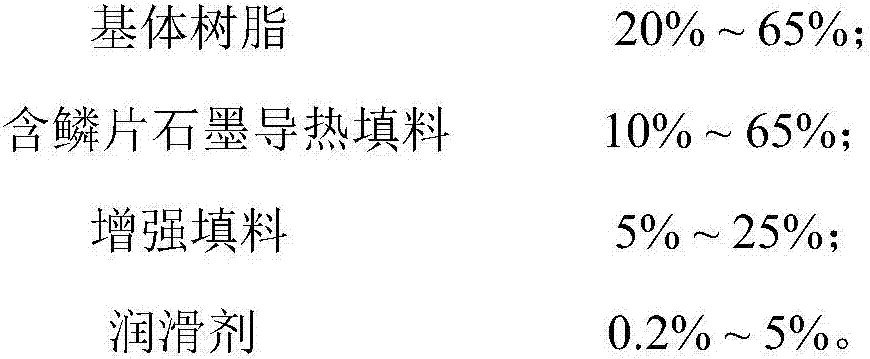

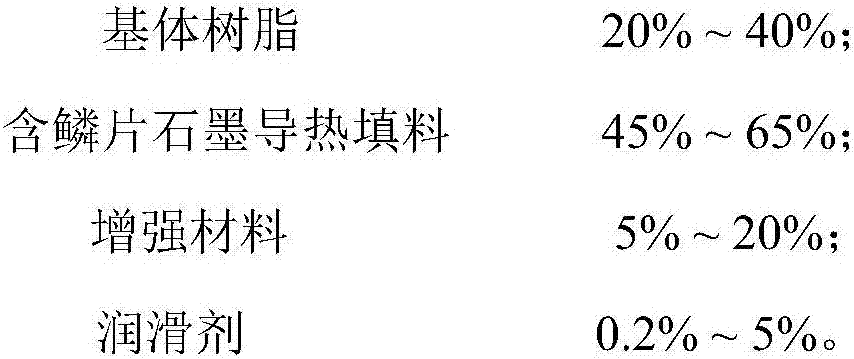

[0031] Preparation of high thermal conductivity composite material: According to the material ratio in Table 1, add PA6 resin, the prepared graphite thermally conductive filler and other additives into the mixer and mix, and then add it to the twin-screw extruder from the main feed por...

Embodiment 2

[0034] Preparation of graphite thermally conductive filler: Weigh 3 parts by weight of flake graphite powder with a D50 particle size of 11μm and 20 parts by weight of non-flake graphite powder with a D50 particle size of 200μm, and mix them uniformly at a high speed at 80°C to obtain a graphite mixture; Put 3 parts by weight of low-viscosity bisphenol A liquid epoxy resin into the planetary power mixer, heat up to 100℃, and slowly put the graphite mixture into the planetary power mixer in 3 times under stirring, and stir to make it uniform After the viscous mixture is put in 2 parts by weight of the tetrakis (2-hydroxyethyl) adipamide curing agent, continue to stir to a small blocky paste.

[0035] Preparation of high thermal conductivity composite material: According to the material ratio in Table 1, add PA6 resin, the prepared graphite thermally conductive filler and other additives into the mixer and mix, and then add it to the twin-screw extruder from the main feed port. The...

Embodiment 3

[0038] Preparation of graphite thermally conductive filler: Weigh 6 parts by weight of flake graphite powder with a D50 particle size of 9.5 μm and 29 parts by weight of non-scale graphite powder with a D50 particle size of 185 μm, and mix them uniformly at a high speed at 80°C to obtain a graphite mixture; Take 5 parts by weight of low-viscosity bisphenol A liquid epoxy resin into the planetary power mixer, heat it up to 100°C, and slowly put the graphite mixture into the planetary power mixer in 3 times under stirring, and stir to make After the uniform and viscous mixture is put into 2 parts by weight of tetrakis (2-hydroxyethyl) adipamide curing agent, continue to stir to a small block paste.

[0039] Preparation of high thermal conductivity composite materials: According to the material ratio in Table 1, add PA46 resin, the prepared graphite thermally conductive filler and other additives into the mixer and mix them, and then add them to the twin-screw extruder from the main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com