Pressure- relief material returning treatment device and method

A technology for processing devices and returning materials, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve problems affecting the accuracy of material proportioning, waste of raw materials, expensive prices, etc., to reduce labor for workers Strength, ease of operation, effect of improving structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0034] The following examples are carried out on the premise of the technical solutions of the present invention, and detailed implementation methods and specific operation processes are provided, but the protection scope of the present invention is not limited to the following examples. The methods used in the following examples are conventional methods unless otherwise specified.

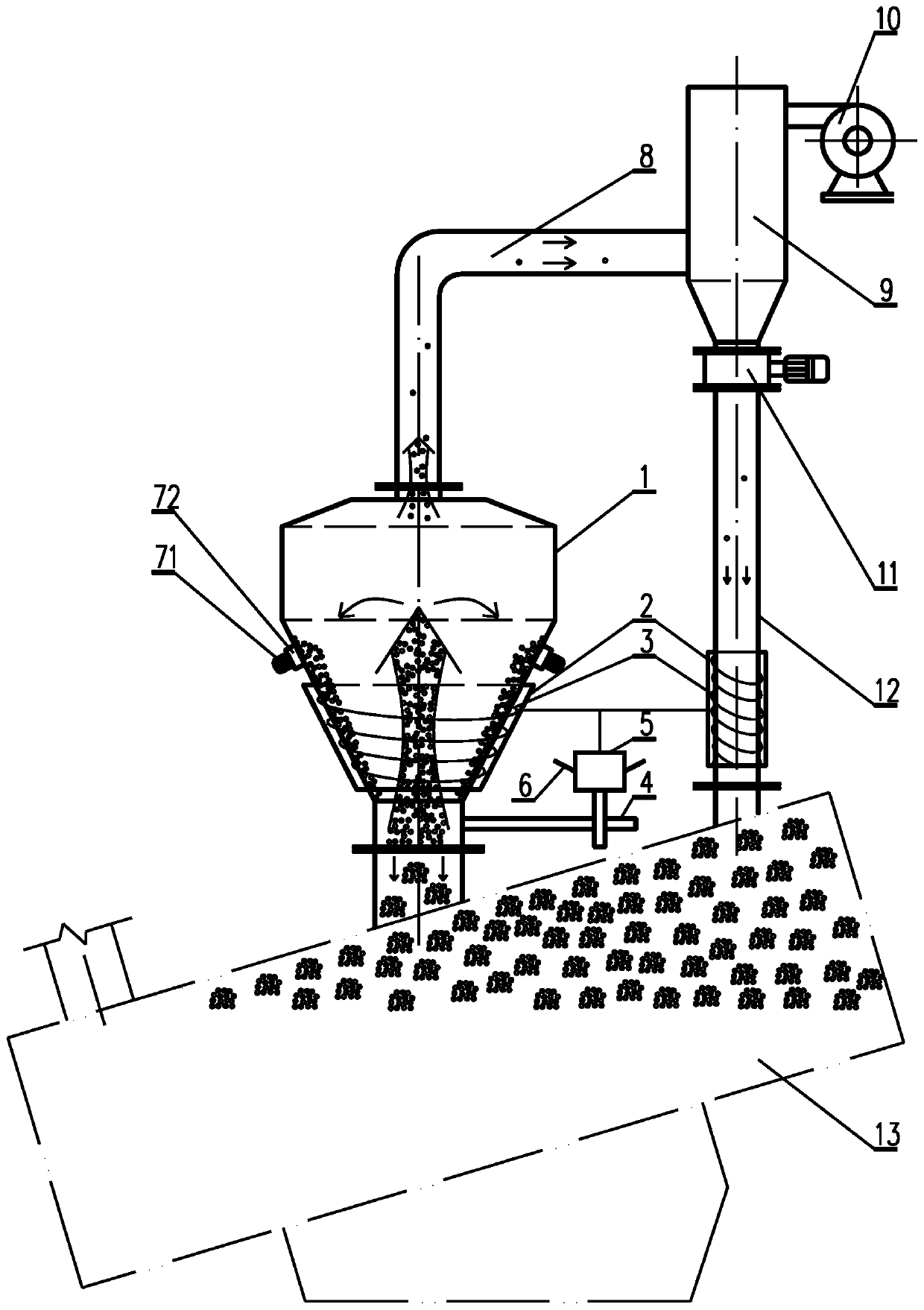

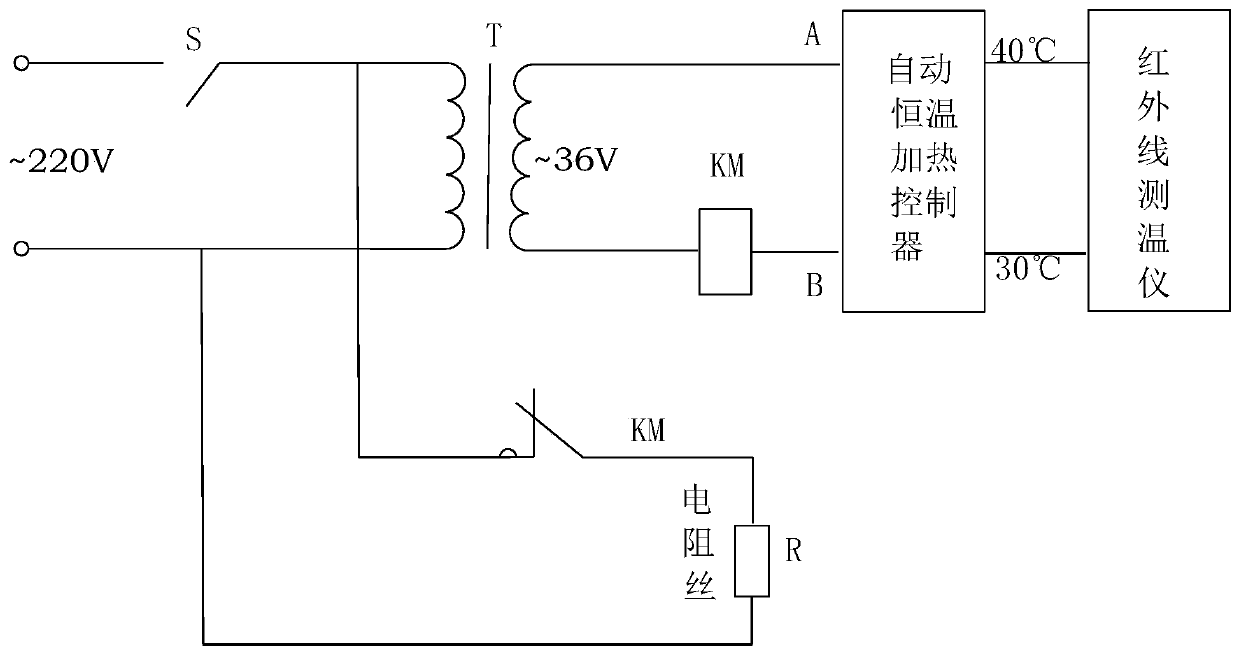

[0035] Such as figure 1 As shown, a pressure relief and return material processing device includes an expansion chamber 1, an insulation layer 2, a resistance wire 3, a bracket 4, an automatic constant temperature heating controller 5, an infrared thermometer 6, an anti-blocking device, a dust removal pipeline 8, and a cloth bag Dust collector 9, induced draft fan 10, electric valve 11, return material pipeline 12. The anti-blocking device consists of a vibration mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com