High-thermal-conductivity modified polyphenyl ether material and preparation method thereof

A technology of polyphenylene ether and high thermal conductivity, which is applied in the field of polyphenylene ether materials and its preparation, can solve problems such as poor thermal conductivity, failure to meet electronic communication components, and no thermal conductivity modification, etc., to improve thermal conductivity and improve uneven mixing , Reduce the effect of screw wear

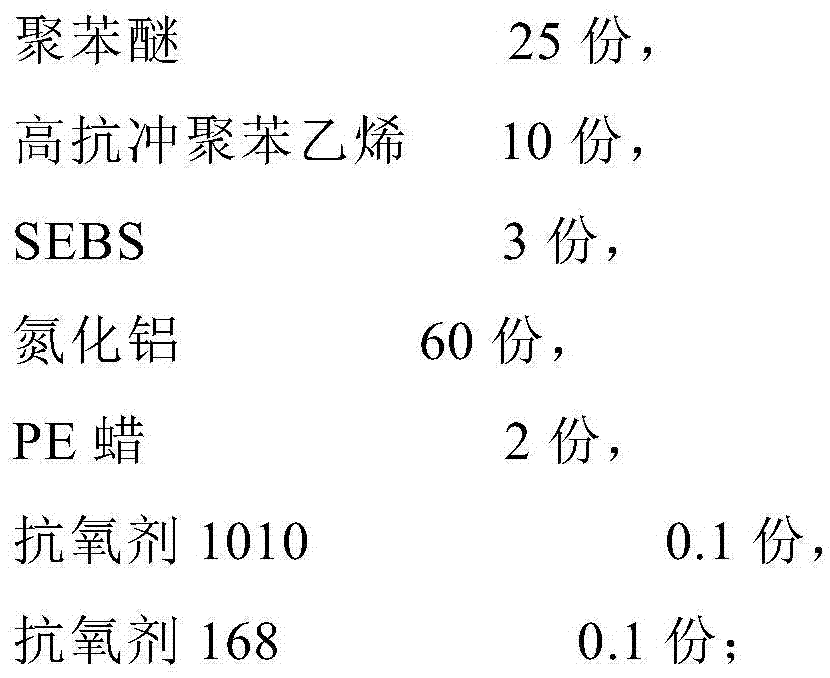

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

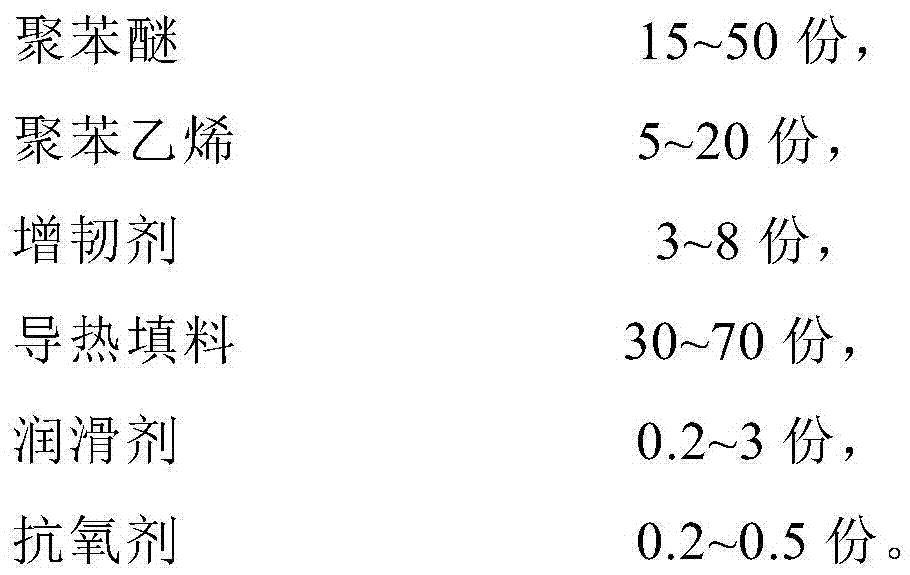

[0026] (1) Take each component raw material by the following parts by weight:

[0027]

[0028] (2) First add boron nitride and OP wax to a high-mixer at 100°C and stir at a high speed for 10 minutes to obtain pretreated boron nitride, then mix the remaining raw materials and pre-treated boron nitride with a high-speed mixer, and the high-mixer The speed of the extruder is 800-1000rmp, the mixing temperature is 40°C, and the mixture is mixed for 10 minutes; the mixed material is passed through the twin-screw extruder, the temperature of each zone is controlled at 260-290°C, and the product is obtained by strand cutting.

Embodiment 2

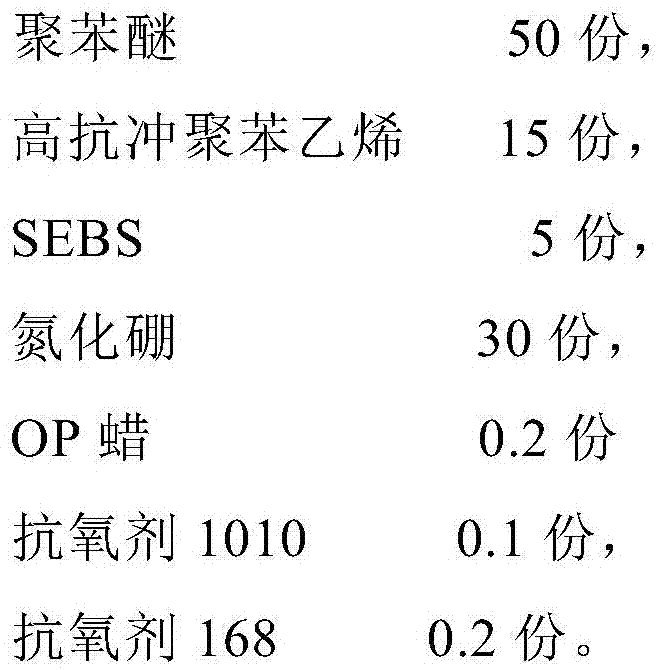

[0030] (1) Take each component raw material by the following parts by weight:

[0031]

[0032] (2) First add aluminum nitride and PE wax to a 130°C high-mixer, and stir at a high speed for 5 minutes to obtain pretreated aluminum nitride, then mix the remaining raw materials and pretreated aluminum nitride at a high speed in a high-mixer to control the high-mixing The machine speed is 800-1000rmp, the mixing temperature is 60°C, and the mixture is mixed for 3 minutes; the mixed material is passed through the twin-screw extruder, and the temperature of each zone is controlled at 240-275°C, and the extruder strands are cut into pellets to obtain the product.

Embodiment 3

[0034] (1) Take each component raw material by the following parts by weight:

[0035]

[0036] (2) First add silicon carbide and silicone to a high mixer at 120°C and stir at high speed for 15 minutes to obtain pretreated silicon carbide, then mix the remaining raw materials and pretreated silicon carbide at high speed in a high mixer, and the speed of the high mixer is 800-1000rmp, the mixing temperature is 50°C, and the mixture is mixed for 6 minutes; the mixed material is passed through a twin-screw extruder, and the temperature of each zone is controlled at 250-280°C, and the strands are cut into pellets to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com