Preparation and application methods of small-grain-size polyimide powder

A polyimide powder and small particle size technology, which is applied in the preparation and application of small particle size polyimide powder, can solve the problems of difficult feeding, uneven particles, high cost, etc., and improve the overall mechanical properties , Simplify the production device and solve the problem of difficult blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

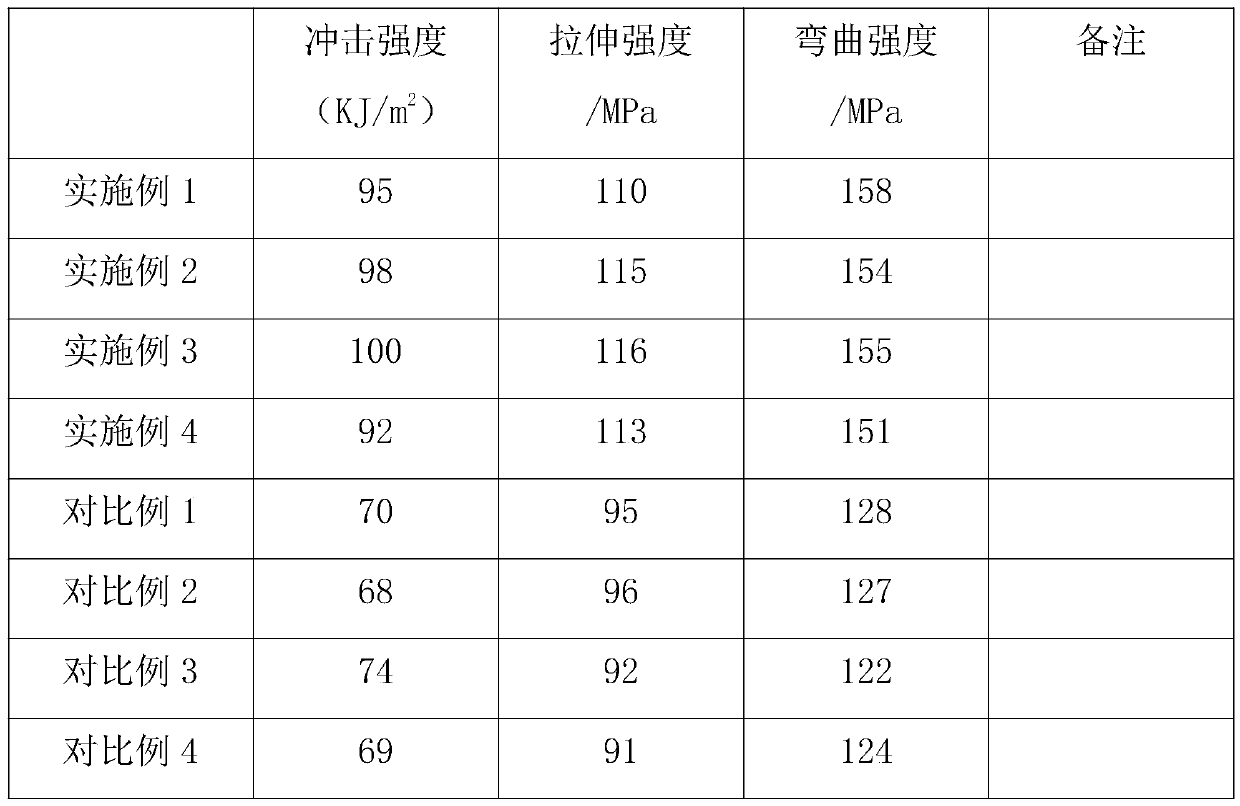

Examples

preparation example Construction

[0027] A preparation method of small particle size polyimide powder, comprising the following steps:

[0028] Dissolve diamine in an organic solvent at room temperature, then add dianhydride to react for 5 hours, add a water separator to raise the temperature to a certain temperature, then pass nitrogen gas and stir for dehydration for 8 hours, then cool down to 90°C, pour the reaction solution into the precipitate while it is hot solution, cooled to normal temperature to crystallize, filtered and dried to obtain resin powder with small particle size, the particle size of polyimide powder is 6μm-15μm. Put the above resin powder into a twin-screw extruder for extrusion granulation, processing temperature: 345°C-360°C, speed: 80r / min-150r / min; Dry in a drying oven for 4 hours, and inject into standard mechanical test specimens by injection molding machine.

Embodiment 1

[0031] Dissolve 20.02g of 4,4'-diaminodiphenyl ether in 167.32g of DMAc at room temperature, slowly add 21.81g of pyromellitic dianhydride, stir and react for 5 hours, then add 33.46g of toluene, blow nitrogen , heated to 155°C and stirred for 8 hours, then cooled to 90°C, poured the reaction solution into 334.64 g of ethanol adjusted to pH 3 with acetic acid, stirred and cooled to room temperature, filtered, and dried at 180°C for 4 hours to obtain a light yellow powder resin , yield 98%. Particle size: D(90)7μm.

Embodiment 2

[0033] Dissolve 24.83g of 4,4'-diaminodiphenylsulfone in 186.56g of NMP at room temperature, slowly add 21.81g of pyromellitic dianhydride, stir and react for 7 hours, then add 37.31g of toluene, and blow argon , heated to 160°C and stirred for 10 hours, then cooled to 80°C, poured the reaction liquid into 373.12 g of methanol whose pH was adjusted to 4 with acetic acid, stirred and cooled to normal temperature, filtered, and dried at 180°C for 4 hours to obtain a light yellow powder resin , yield 97%. Particle size: D(90)6μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com