Feeding funnel device of tablet press

A technology of feeding funnel and tablet press, applied in the direction of presses, manufacturing tools, etc., can solve the problems of reduced production efficiency, excessive feeding of fine powder, difficulties, etc., to improve production efficiency, increase corporate profits, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

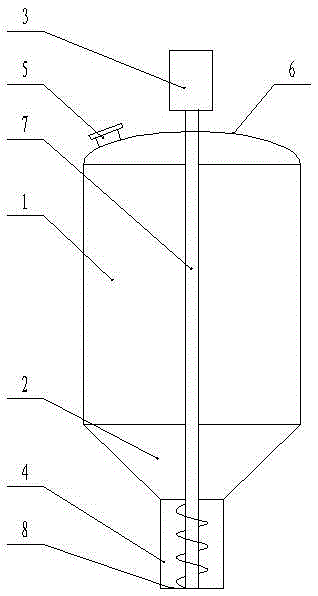

[0034] like figure 1 As shown, a feeding hopper device for a tablet press includes: a motor 3, a threaded rod 7, a first hopper 1 and a second hopper 2; the first hopper 1 is provided with an end cap 6, and the The end cover 6 is provided with a feed inlet 5, the second hopper 2 is an inverted conical transition hopper arranged below the first hopper 1, and the lower part of the second hopper 2 is connected with a feeding pipe 4, and the feeding pipe The lower discharge port 8 of 4 is connected to the tablet press; the tail end of the threaded rod 7 passes through the end cover 6 and is connected with the motor 3 arranged on the end cover 6, and the lower end of the threaded rod 7 is flat with the lower discharge port 8 and the axis of the threaded rod 7 coincides with the axes of the first hopper 1, the second hopper 2 and the feed pipe 4; at least one section of the threaded rod 7 located in the feed pipe 4 is provided with a thread, and the thread is used for feeding The ...

Embodiment 2

[0036] A feed hopper device for a tablet press, the structure of which is basically the same as the hopper device in Example 1, the difference is that the parts of the threaded rod 7 located in the second hopper 3 and the feeding pipe 4 are all provided with threads.

Embodiment 3

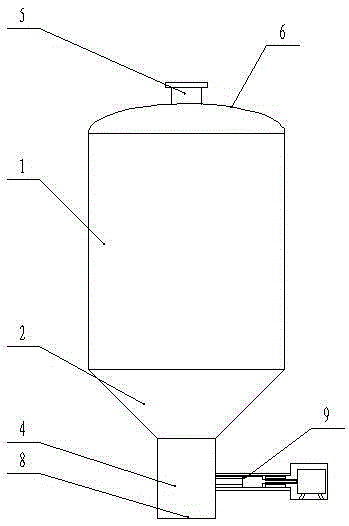

[0038] like Figure 2-Figure 5 As shown, a feeding hopper device for a tablet press includes: a first hopper 1 and a second hopper 2; the first hopper 1 is provided with an end cover 6, and the end cover 6 is provided with an inlet The feed opening 5, the second hopper 2 is an inverted conical transition hopper arranged below the first hopper 1, the lower part of the second hopper 2 is connected with a feeding pipe 4, and the lower outlet 8 of the feeding pipe 4 Connect to tablet press.

[0039] The funnel device is also provided with a stirring device 9, and the stirring device 9 is composed of a stirring mechanism, a push-out mechanism 94, and a power mechanism.

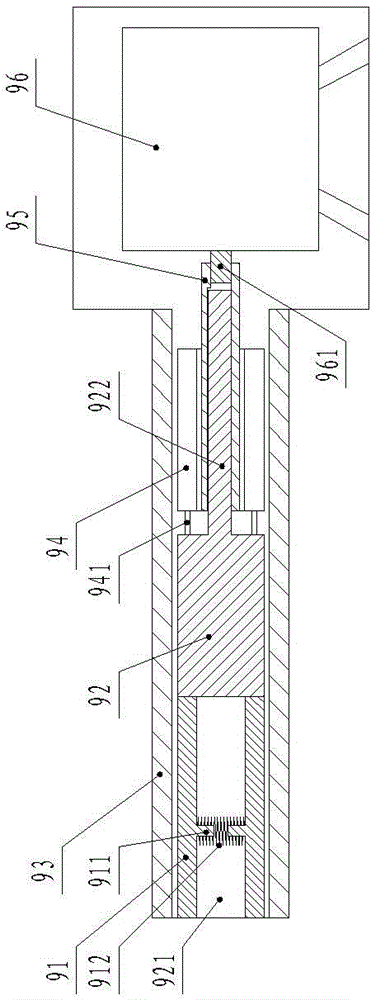

[0040] The stirring mechanism includes a support rod 91 and a stirring rod body 92. The stirring rod body 92 includes a connecting section, the connecting section is a short cylinder, and one end of the connecting section is fixedly provided with two supporting rods 921. Between the two poles 921 is a receiving gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com