Abutment earth pressure elimination based abutment structure and construction method

A construction method and earth pressure technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as bridge abutment damage, abutment jumping phenomenon, economic loss, etc., to avoid bending damage and improve the overall mechanical performance And the comfort of driving, the effect of not easy to settle and fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

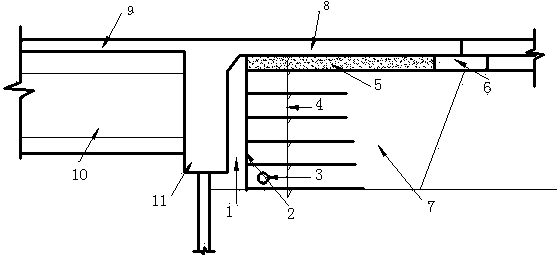

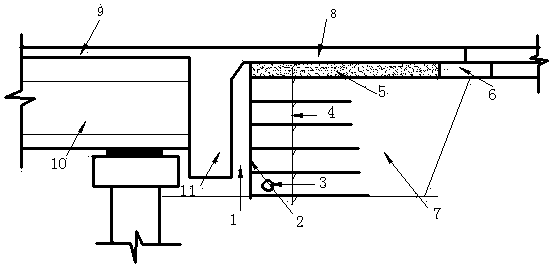

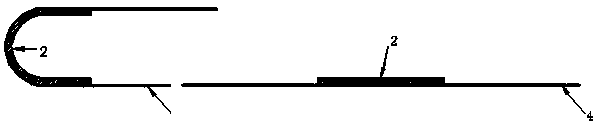

[0026] Such as Figure 1~3 As shown, an abutment structure based on eliminating the earth pressure of the abutment includes an abutment 11, the abutment 11 is connected with a bridge deck 9 and a butt plate 8, and the bottom of the bridge deck 9 is provided with a bridge abutment 11. The main girder 10 of the main beam 10, one end of the strapping plate 8 is connected to the abutment 11, and the other end is arranged on the corbel 6, and an embankment 7 with a local reinforcement structure is arranged below the corbel 6, and the embankment 7 and the strapping plate 8 is filled with a fine sand cushion 5, and a gap 1 is provided between the embankment 7 and the abutment 11, and the gap 1 ensures that there is no gap between the abutment 11 and the embankment 7 under the condition of the temperature difference between day and night and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com