Integral abutment based on corrugated steel plates and construction method thereof

An integral abutment and corrugated steel web technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unfavorable structures and complex stress conditions, and achieve the effect of prolonging service life and ensuring vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

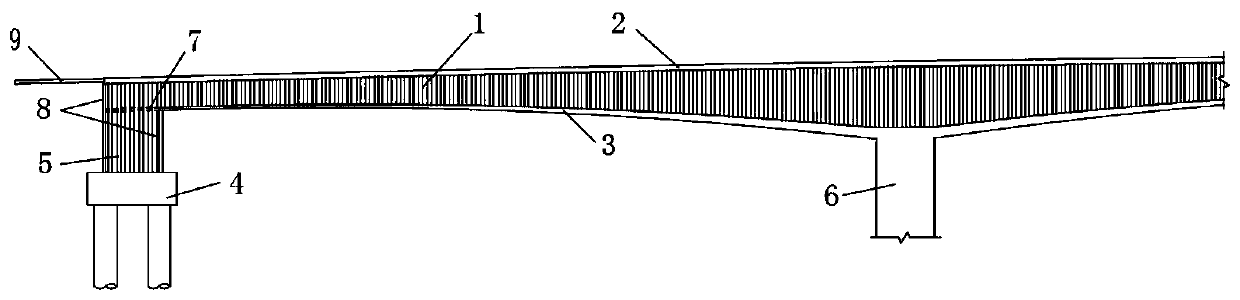

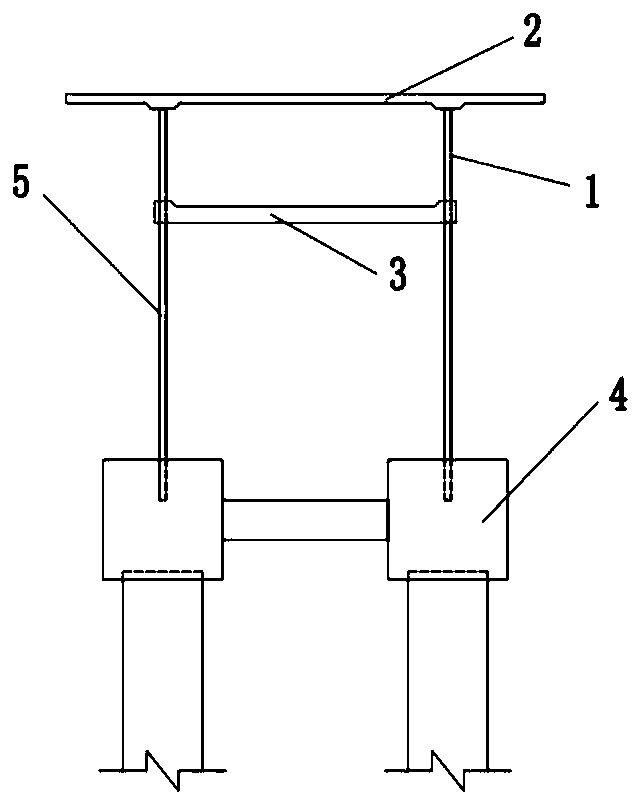

[0038] Such as Figure 1 to Figure 3 As shown: the integral abutment based on corrugated steel plates in this embodiment includes a box girder and several abutment foundations 4 for supporting the box girder. The box girder includes a concrete roof 2, a concrete bottom 3 and a corrugated rigid web. The slabs are respectively connected to the concrete top slab 2 and the concrete bottom slab 3; the end of the corrugated steel web is connected to the abutment foundation 4 through the corrugated steel plate group, and the bottom end of the middle part of the corrugated steel web 1 extends downward and is inserted into the pier 6. In this embodiment, the corrugated steel plate group includes only one corrugated steel plate 5 .

[0039] The box girder includes at least two corrugated steel webs 1, and the corrugated steel webs 1 are connected with the concrete top plate 2 and the concrete bottom plate 3 of the box girder through perforated steel plates and / or welding nails to form a...

Embodiment 2

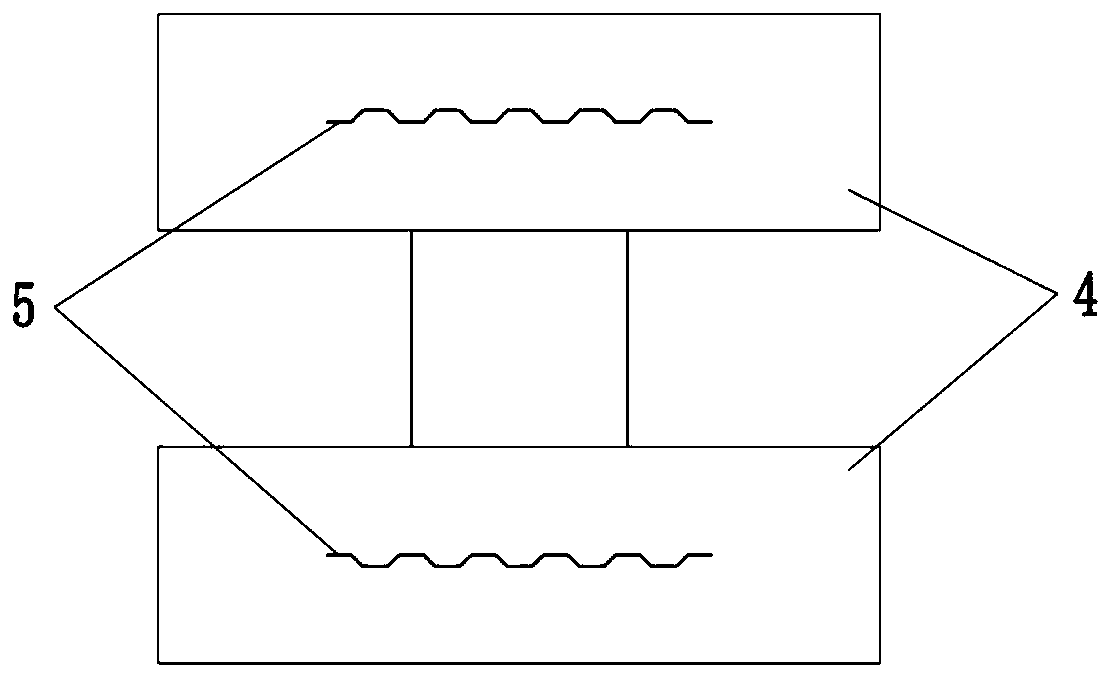

[0053] Such as Figure 4 As shown, this embodiment provides an integral abutment based on corrugated steel plates. Compared with Embodiment 1, the difference lies in that the corrugated steel web 1 of the box girder in this embodiment corresponds to the corrugated steel plate group of the abutment It includes two or three corrugated steel plates 5 parallel to each other.

Embodiment 3

[0055] Such as Figure 5 As shown, the difference between the present embodiment and the first embodiment is that: the corrugated steel plate 5 in the present embodiment is provided with a vertical stiffener 10, and the stiffener 10 is a plate rib or a T rib.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com